Conical hood mechanism of titanium slag furnace

A conical, titanium slag technology, applied in the field of conical hood mechanism of titanium slag furnace, can solve the problem that the protective performance cannot meet the requirements of titanium slag smelting, etc. The effect of reducing the circulating water temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

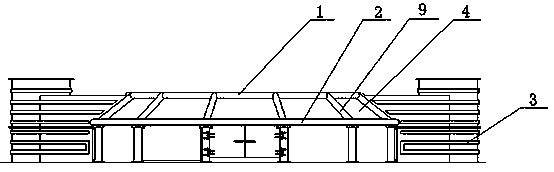

[0018] like figure 1 and figure 2 As shown, the conical fume hood mechanism of this titanium slag furnace includes the main beam composed of the outer cone 1 and the inner cone 2. The welding seam of the main beam is reduced, the inner cone 2 is located above the outer cone 1, and the diameter of the inner cone 2 is smaller than the diameter of the outer cone 1, and there are several auxiliary beams 9 between the outer cone 1 and the inner cone 2 The connection is fixed, the gap formed between the main beam and the sub-beam 9 is fixed with a cover plate 4, and the outside of the outer cone 1 is also connected with a dust suppression box 3, thus forming a conical smoke hood structure, and all the sub-beams 9 are It is the butt joint of the whole seamless steel pipe, and all welds are under pressure, thus realizing a seamless skeleton and changing the original historical pattern of channel steel butt joint, polygonal splicing, large weld seam volume and easy cracking.

[0019...

Embodiment 2

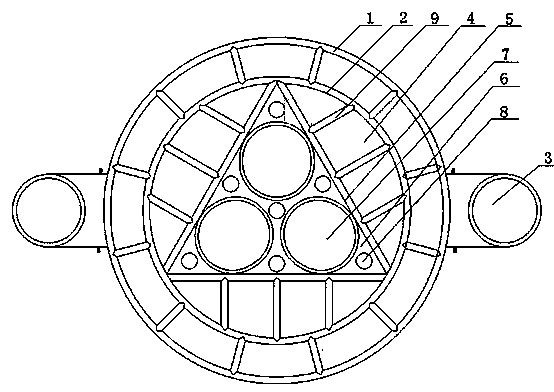

[0024] The inner side of the inner cone circle 2 is ring-connected with a triangular frame 5 , and inside the triangular frame 5 is a polar center circle area 6 , which is reserved for electrode holes 7 and feeding holes 8 on the cover plate 4 .

[0025] Each side of the triangular frame 5 is fixedly connected to the adjacent points of the inner cone circle 2 through several sub-beams 9, and the gap between the triangular frame 5 and the inner cone circle 2 is also fixed with a cover plate 4, thereby increasing the strength of the triangular frame 5. Stability, in this embodiment, three sub-beams 9 connected with the inner cone circle 2 are uniformly fixed on each side.

[0026] Three electrode holes 7 of the same specification are distributed symmetrically in a triangular shape in the triangular frame 5, and the three graphite electrodes are respectively extended from the three electrode holes 7 to the titanium slag furnace. There are several blanking holes 8 on the blank cov...

Embodiment 3

[0028] There are two floor-standing water-cooled dust suppression boxes 3 arranged symmetrically on the outside of the outer cone 1, and the upper part of the dust suppression box 3 is a flue. These two dust suppression boxes 3 can directly absorb 60% of the flue gas temperature in the titanium slag furnace flue gas, and improve the temperature of the dust collector. The service life of the cloth bag is more than 3 times. Because it is located in the symmetrical position on both sides of the outer cone 1, the rolling smoke cloud formed with the conical furnace cover can just be sucked away, just like the suction port of a tornado. Put an end to the unorganized emission of smoke, and fundamentally solve the unfavorable historical situation of smoke pollution in the workshop.

[0029] The large particle attachments in the flue can be discharged into the dust suppression box 3 in an organized manner, and there is no possibility of polluting the production environment, which effect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com