LED (Light-Emitting Diode) wafer modularized packaging process

A packaging process and LED chip technology, which is applied in lighting devices, lighting and heating equipment, electrical components, etc., can solve the problems of low LED chip packaging efficiency and high cost, and achieve high efficiency of packaging manufacturing process, increase production capacity, and increase speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with drawings and embodiments.

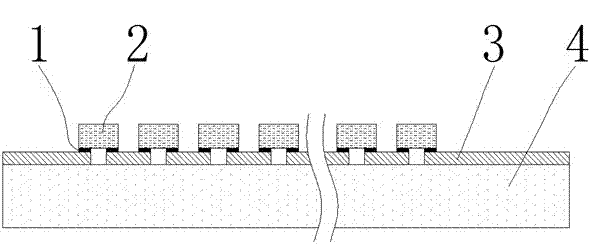

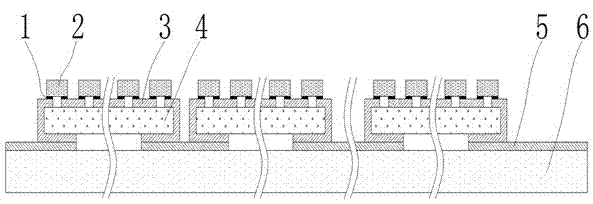

[0012] The specific steps of the LED chip modular packaging process of the present invention are as follows: first, a single or multiple LED chips with a front-mounted or flip-chip structure are connected in series and parallel to form an LED chip group, and then the LED chip group is pasted with an LED chip placement device. to the substrate or support.

[0013] After single or multiple LED chips are connected in series and parallel to form an LED chipset, the lead wires are metal wires, metal thin film wires or indium tin oxide (ITO) transparent wires. On the lead-out wire, the flip-chip LED chip is welded on the lead-out wire with eutectic solder joints.

[0014] The LED chip placement equipment is a solid crystal machine or a placement machine. The welding materials used for welding the LED chip and the lead wire are solder wire, solder paste and conductive adhesi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com