Amoxicillin granules and preparation technology of same

A technology of amoxicillin and granules, applied in the field of amoxicillin granule preparation and preparation thereof, can solve the problems of large amount of solvent and high safety risk of high-concentration ethanol, and achieves reduction of polymer impurities, improvement of production safety, and improvement of solubility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

reference example 1

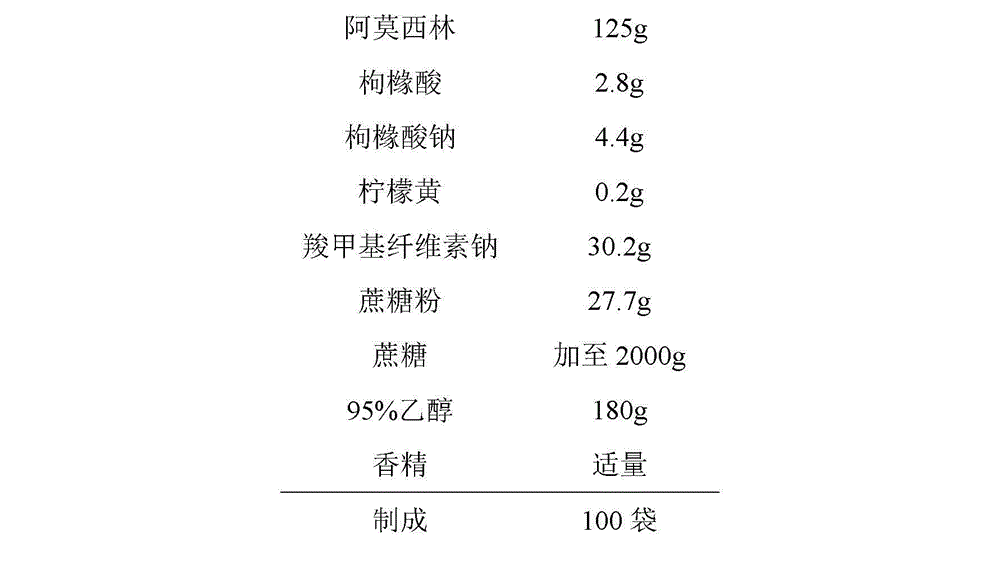

[0017] Example 1 in the patent CN102000033B.

[0018]

[0019] Preparation Process:

[0020] (1) Weigh Amoxicillin.

[0021] (2) Mix and grind citric acid, sodium citrate, lemon yellow and sucrose through an 80-mesh sieve.

[0022] (3) Prepare the binder solution, and prepare 1.0wt% sodium carboxymethylcellulose in 95% ethanol and 66.52wt% syrup in proportion.

[0023] (4) Mix amoxicillin and excipients, add binder solution, place in the hopper of a high-efficiency wet granulator, close the material box, turn on the paddle and cutter and mix at low speed for 5 minutes, stop stirring, and add 95% Appropriate amount of ethanol, turn on the paddle stirring and cutter, stir at a slow speed for 120 seconds, stop stirring, add 1% sodium carboxymethyl cellulose slurry, and stir at a high speed for 60 seconds, add syrup from the observation port, and stir at a high speed From 180 seconds to 240 seconds, use the cleaned and disinfected material barrel to receive the wet granules,...

reference example 2

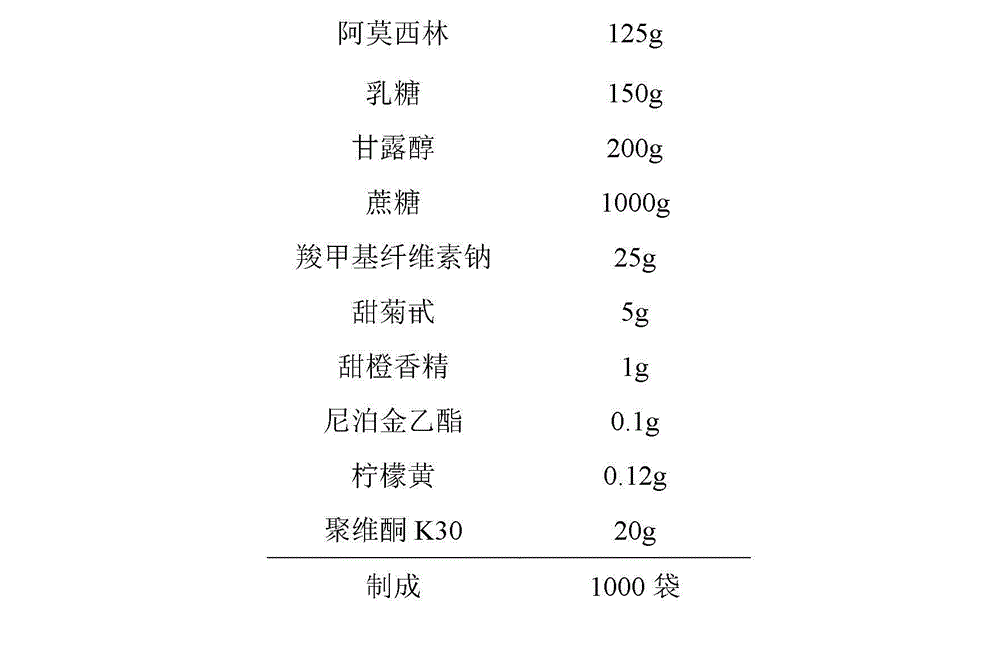

[0028]

[0029] Preparation Process

[0030] (1) Weigh amoxicillin, lactose, mannitol, stevioside, sucrose, and sodium carboxymethylcellulose for subsequent use;

[0031] (2) Configuration of adhesive solution:

[0032] Put povidone K30, ethyl paraben, tartrazine, and sweet orange essence into 80 g of purified water and stir to dissolve to prepare a binder solution.

[0033] (3) Put amoxicillin, lactose, mannitol, sucrose, sodium carboxymethyl cellulose, and stevioside into the wet granulator, turn on the motor of the stirring paddle, and stir for 10 minutes; open the cover and add the adhesive solution, the granulation time is about 3 minutes.

[0034] (4) After the granulation is completed, open the discharge piston, and move the stirring paddle to discharge the wet granules. The wet granules are granulated with a wet granulator (the mesh number of the screen is 16 mesh).

[0035] (5) Start the blower to suck the material into the boiling dryer. The air inlet tempera...

Embodiment 1

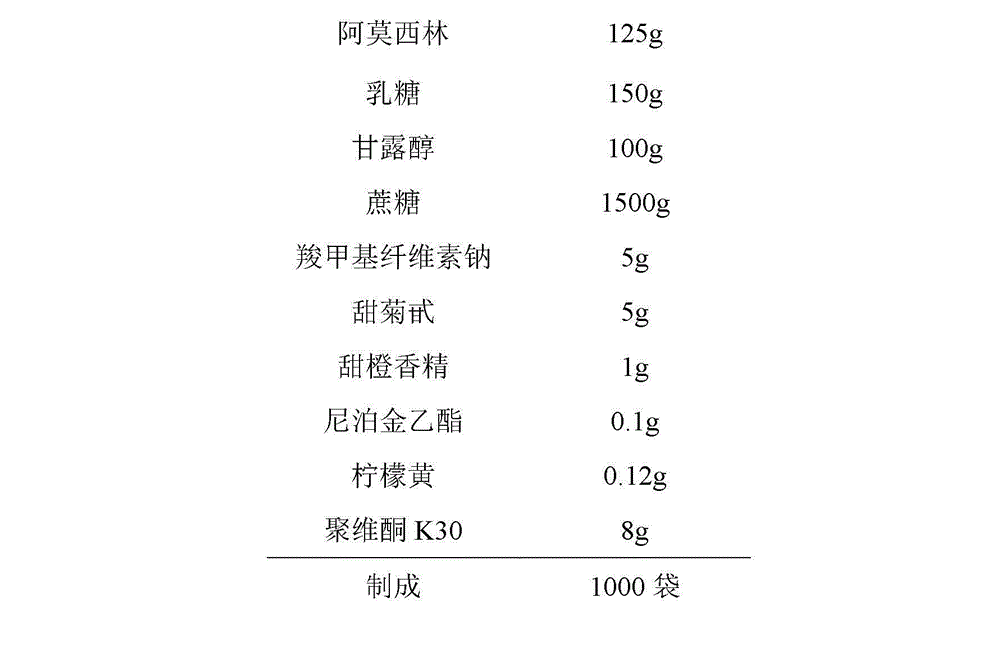

[0039]

[0040] Preparation Process

[0041] (1) Weigh amoxicillin, lactose, mannitol, stevioside, sucrose, and sodium carboxymethylcellulose for subsequent use;

[0042] (2) Configuration of adhesive solution:

[0043] Put povidone K30, ethyl paraben, tartrazine, and sweet orange essence into 80 g of purified water and stir to dissolve to prepare a binder solution.

[0044] (3) Put amoxicillin, lactose, mannitol, sucrose, sodium carboxymethyl cellulose, and stevioside into the wet granulator, turn on the motor of the stirring paddle, and stir for 10 minutes; open the cover and add the adhesive solution, the granulation time is about 3 minutes.

[0045] (4) After the granulation is completed, open the discharge piston, and move the stirring paddle to discharge the wet granules. The wet granules are granulated with a wet granulator (the mesh number of the screen is 16 mesh).

[0046] (5) Start the blower to suck the material into the boiling dryer. The air inlet tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com