Catalytic cracking double-metal deactivator

A catalytic cracking and bimetallic technology, applied in catalytic cracking, catalyst protection, cracking, etc., can solve the problems of high toxicity, poor compounding performance, increase the amount of CO combustion aid, etc., achieve high effective metal content and increase regeneration yield , the effect of improving the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

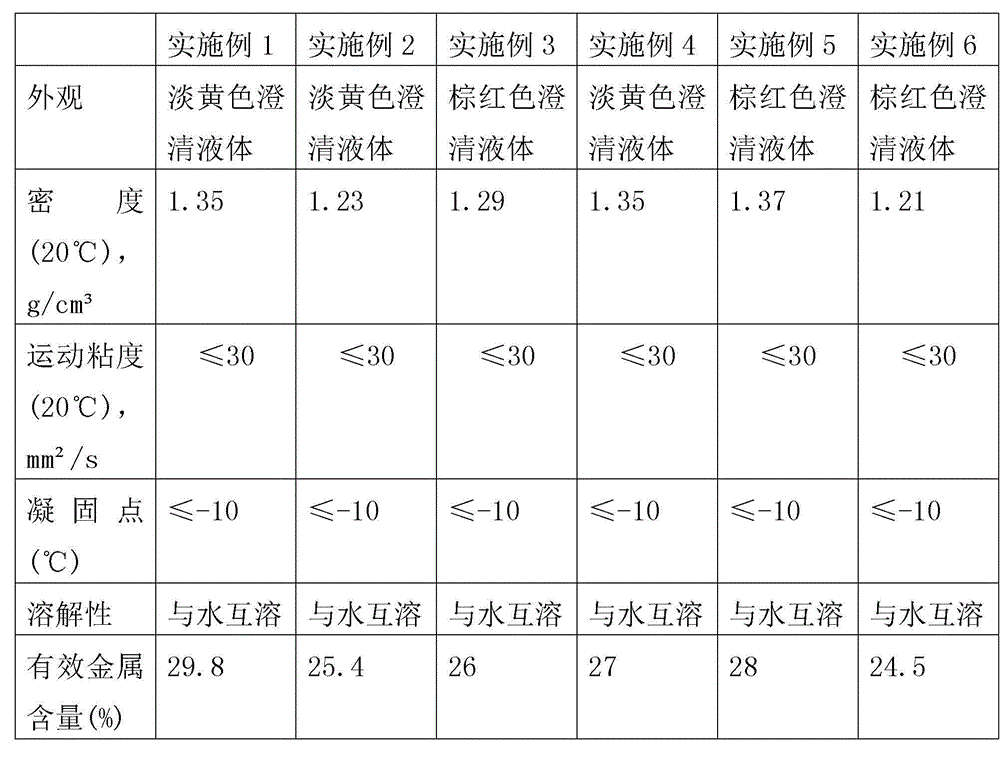

Examples

Embodiment 1

[0018] A catalytic cracking bimetallic passivator, wherein the content of antimony in the antimony single agent is 21%, the content of cerium in the cerium single agent is 8.8%, and the rest is water. The specific preparation steps include:

[0019] (1) Preparation of antimony single agent: put 30g of water, 30g of tartaric acid and 30g of antimony trioxide into the reaction kettle in turn and stir, add 10g of monoethanolamine to prevent bumping, after the dropwise addition, control the temperature at 75°C, and then heat to boiling , reflux for 22 minutes, and discharge after cooling to form a single agent of antimony;

[0020] (2) Preparation of cerium single agent: put 30g of water, 21g of tartaric acid and 19g of monoethanolamine into the reactor and stir for 30min, add 30g of rare earth powder to prevent carbon dioxide gas from overflowing the reactor, after the dropwise addition, stir for 30min and heat up to 102°C Boil, reflux for 1 hour, and discharge after cooling to f...

Embodiment 2

[0023] A catalytic cracking bimetal passivator, wherein the antimony content in the antimony single agent is 19%, the cerium content in the cerium single agent is 6.4%, and the rest is water. The specific preparation steps include:

[0024] (1) Preparation of antimony single agent: put 30g of water, 27.5g of tartaric acid and 31g of antimony trioxide into the reaction kettle in order to stir, add 11.5g of monoethanolamine to prevent bumping, dropwise, control the temperature at 75°C, and then heat Bring to boiling, reflux for 22 minutes, discharge after cooling, and serve as antimony single agent;

[0025] (2) Preparation of cerium single agent: put 30g of water, 22g of tartaric acid and 18g of monoethanolamine into the reactor and stir for 30min, add 30g of rare earth powder to prevent carbon dioxide gas from overflowing the reactor, after the dropwise addition, stir for 30min and heat up to 102°C Boil, reflux for 1 hour, and discharge after cooling to form a cerium single do...

Embodiment 3

[0028] A catalytic cracking bimetallic passivator, wherein the content of antimony in the antimony single agent is 18%, the content of cerium in the cerium single agent is 8%, and the rest is water. The specific preparation steps include:

[0029] (1) Preparation of antimony single agent: put 30g of water, 29.8g of tartaric acid and 30g of antimony trioxide into the reaction kettle in order to stir, add 10.2g of monoethanolamine to prevent bumping, after the dropwise addition, control the temperature at 75°C, and then heat Bring to boiling, reflux for 22 minutes, discharge after cooling, and serve as antimony single agent;

[0030] (2) Preparation of cerium single agent: put 30g of water, 20g of tartaric acid and 18g of monoethanolamine into the reactor and stir for 30min, add 32g of rare earth powder to prevent carbon dioxide gas from overflowing the reactor, after the dropwise addition, stir for 30min and heat up to 102°C Boil, reflux for 1 hour, and discharge after cooling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com