Device and method for performing ultraviolet cleaning on nano-patterns

A nano-patterning and external cleaning technology, applied in cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of poor cleaning uniformity of silicon wafers, adverse effects, low ozone concentration, etc., and achieve good development and application prospects. Reduced energy consumption and uniform cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

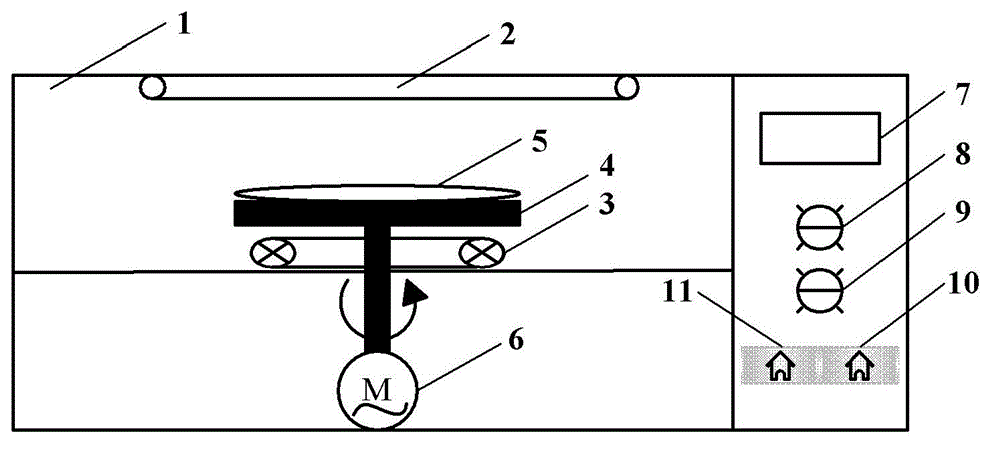

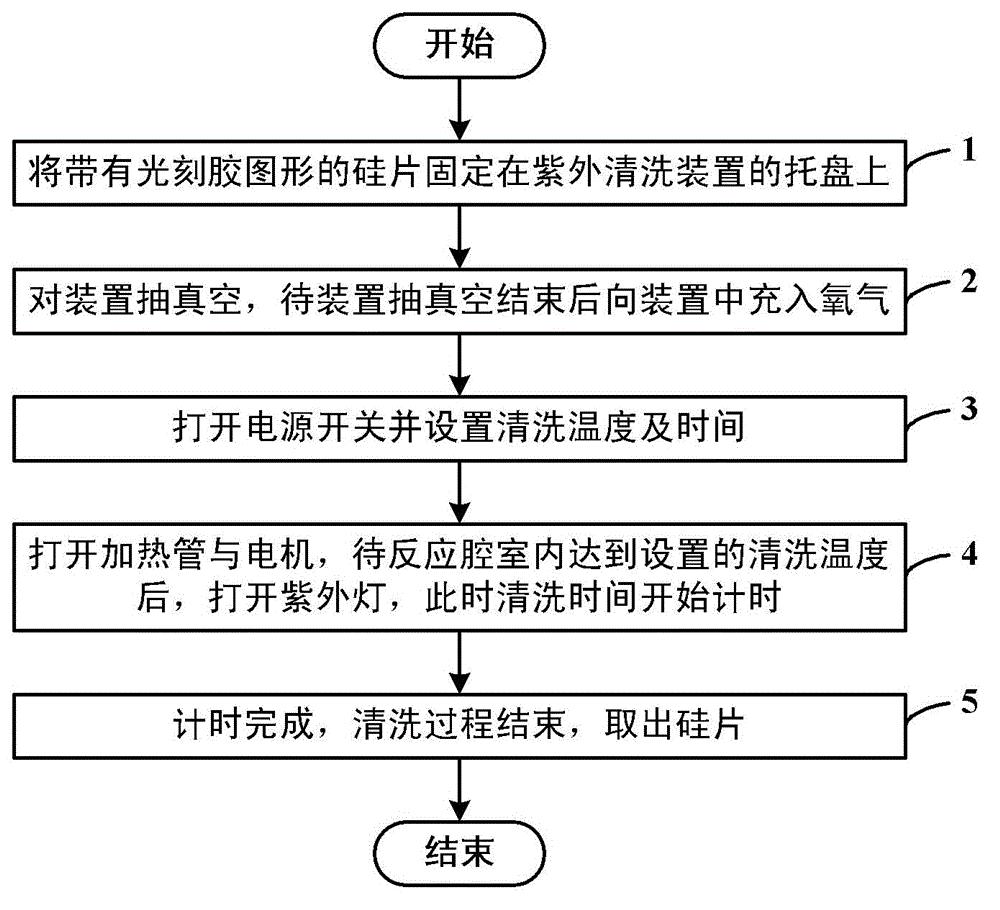

[0022] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

[0023] The realization principle of the present invention is firstly introduced below. After the CMOS process enters the 22ns node, there is no better way to remove the high molecular polymers that appear after electron beam lithography. Oxygen molecules in the air will also produce ozone and atomic oxygen after absorbing ultraviolet light. Under different bands of ultraviolet radiation, it is decomposed into atomic oxygen and oxygen, among which atomic oxygen is extremely active. Under its action, the high molecular polymer composed of carbon and hydrocarbons on the nanometer pattern can be decomposed into volatile gases . The invention controls the intensity and irradiation time of the ultraviolet rays and the surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com