Wood modifier and preparation method thereof

A modifier and wood technology, applied in the directions of impregnating wood, wood impregnation, wood processing appliances, etc., can solve the problems of poor bleed resistance, no contribution to wood dimensional stability, and achieve low cost, remarkable flame retardant effect, and preparation method. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

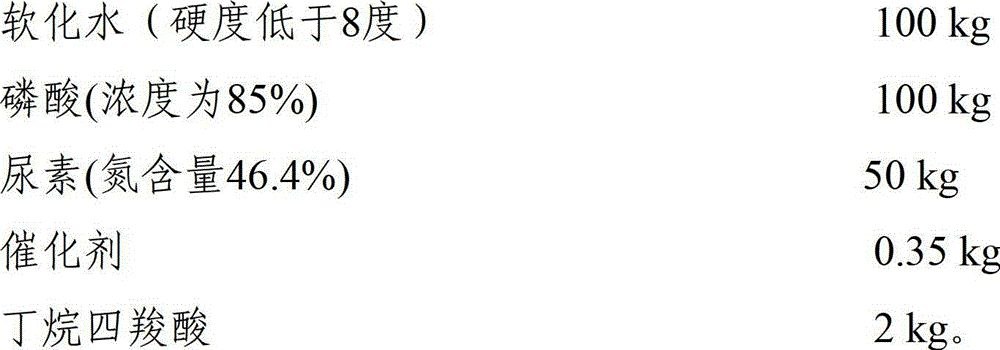

[0041] 1. Prepare raw materials according to the following weight ratio:

[0042]

[0043] The catalyst is a light yellow-green powder prepared by the Environmental Protection Flame Retardant Technology Center of the School of Materials Science and Technology, Beijing Forestry University: 40g of tin chloride, 80g of copper sulfate, 35g of sodium chloride, 40g of ferric chloride, 40g of aluminum sulfate, 45g of boric acid and chlorine Zinc chloride 70g (grinded according to the proportion and then pulverized evenly).

[0044] 2. Preparation method:

[0045] 1) In the reaction kettle equipped with a mixer, temperature and pressure monitor and condenser, add the phosphoric acid in the reaction raw materials, stir and heat at the same time, so that the temperature rises to 60°C;

[0046] 2) Add all urea into the reactor, and continue to stir the mixture of phosphoric acid and urea at the same time, so that the material is distributed and heated evenly;

[0047] 3) Continue he...

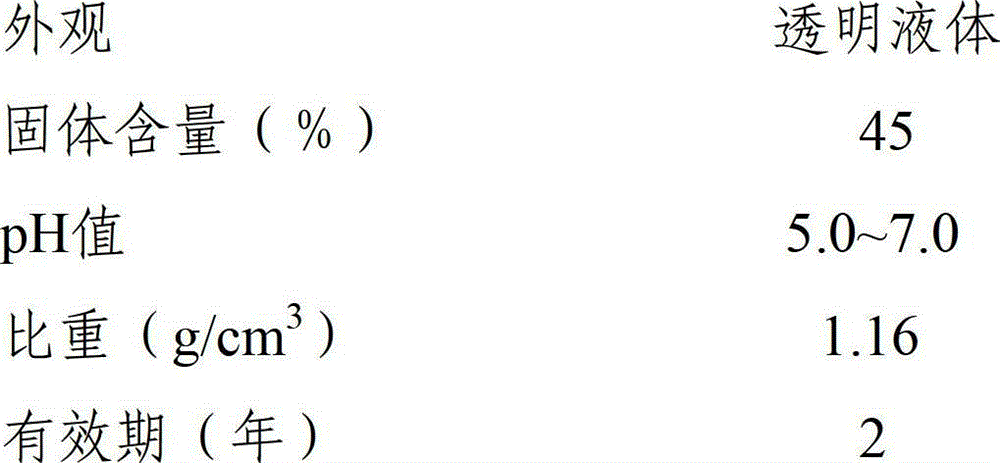

Embodiment 2

[0054] 1. Prepare raw materials according to the following weight ratio:

[0055]

[0056] The catalysts are: 40g of tin chloride, 135g of copper sulfate, 45g of sodium chloride, 45g of ferric chloride, 65g of aluminum sulfate, 65g of boric acid and 85g of zinc chloride (evenly pulverized after grinding according to the proportion).

[0057] 2. Preparation method:

[0058]1) In a reaction kettle equipped with a mixer, a temperature and pressure display, and a condenser, add phosphoric acid in the reaction raw materials, stir and heat at the same time, so that the temperature rises to 50°C;

[0059] 2) Add urea into the reactor, and at the same time continue to stir the mixture of phosphoric acid and urea, so that the material is distributed and heated evenly;

[0060] 3) Continue heating to raise the temperature to 115°C, slowly and evenly add the catalyst to the reaction kettle to make the mixture react;

[0061] 4) Continue heating until the temperature reaches 140°C, a...

Embodiment 3

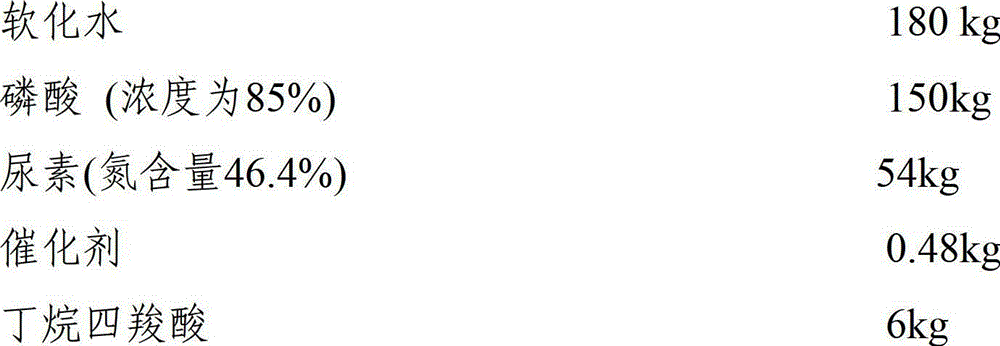

[0067] 1. Prepare raw materials according to the following weight ratio:

[0068]

[0069]

[0070] The catalysts are: 35g of tin chloride, 45g of copper sulfate, 35g of sodium chloride, 35g of ferric chloride, 25g of aluminum sulfate, 25g of boric acid and 80g of zinc chloride (evenly pulverized after grinding according to the proportion).

[0071] 1) In the reaction kettle equipped with a mixer, temperature and pressure monitor and condenser, add the phosphoric acid in the reaction raw materials, stir and heat at the same time, so that the temperature rises to 60°C;

[0072] 2) Add urea into the reaction kettle, and continue to stir the mixture of phosphoric acid and urea, so that the material is distributed and heated evenly;

[0073] 3) Continue heating to raise the temperature to 110°C, slowly and evenly add the catalyst to the reaction kettle to make the mixture react, and the reaction material turns light green;

[0074] 4) Continue heating until the temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com