Glass powder of water-based glass ionomer cement and preparation method thereof

A glass powder, glass technology, applied in the direction of dental preparations, dental prostheses, pharmaceutical formulations, etc., can solve problems such as high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

[0045] Embodiment 1-4 glass powder and its preparation

[0046] According to the chemical raw material components of the glass powder of the dental water-based glass ionomer cement of the present invention, four batches of glass powders, namely the four examples in the table below, were prepared by using the preparation method of the present invention. in,

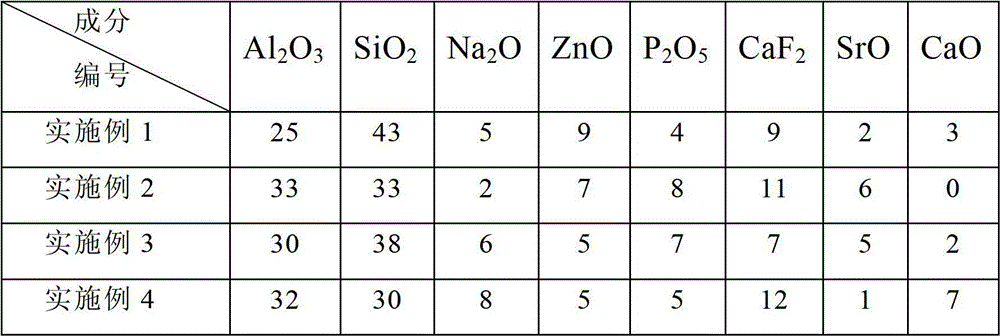

[0047] Table 1 is the raw material composition table of the glass powder of four embodiments of the present invention;

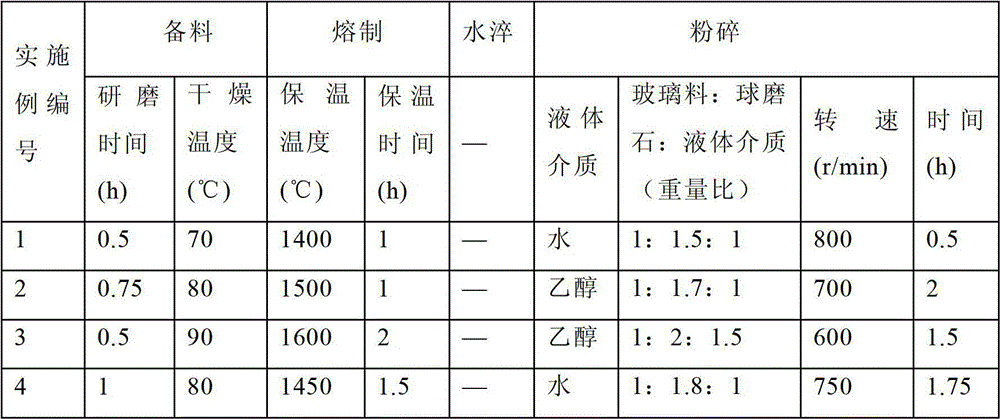

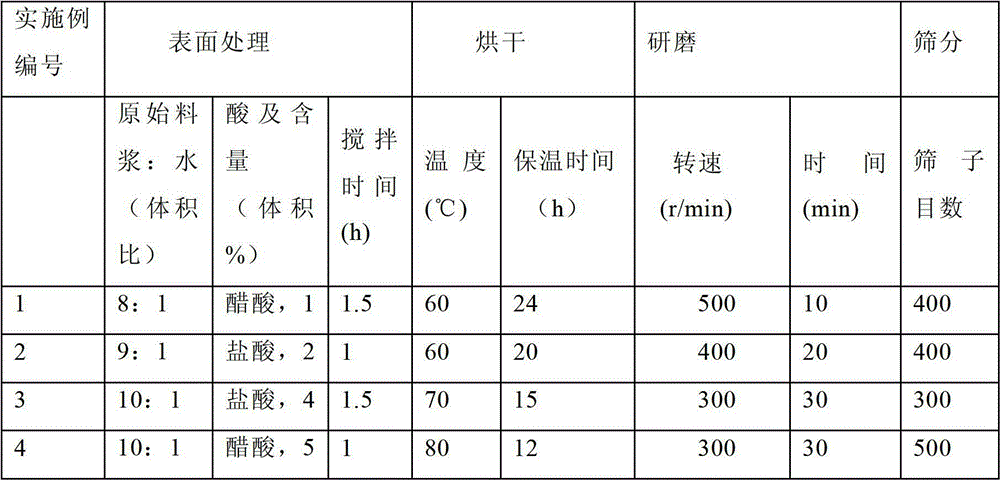

[0048] Table 2-A and Table 2-B are the process steps and process parameter tables of four embodiments of the glass powder preparation method of the present invention;

[0049] Table 3 shows the particle size distribution of the glass powder prepared in Example 3 of the present invention.

[0050] Table 1 Raw material composition list (mass %) of the glass powder of the present invention

[0051]

[0052] Table 2-A Process steps and process parameter table of the glass powder preparation method of t...

Embodiment 5

[0075] Get 3.3g of the glass powder obtained in Example 1, and then take 1.0g of Fuji's GC II type glass ionomer cement liquid, put them respectively on the mixing paper for subsequent use, and use a plastic spatula to divide the powder evenly into two First, add the first part to the liquid and mix for 10 seconds, then add the remaining powder and mix for 15-20 seconds to obtain the test cement paste, and measure the net cement paste after the glass powder and liquid are cured according to the above method. Curing time and compressive strength, the results are shown in Table 4.

Embodiment 6

[0077] In Example 5, the glass powder prepared in Example 1 was replaced with the glass powder prepared in Example 2. Others were the same as in Example 5. The performance test results are shown in Table 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com