Hydrolysis resistant urethane resin for garment synthetic leather as well as preparation method and application thereof

A polyurethane resin, hydrolysis-resistant technology, used in textiles and papermaking, etc., can solve the problems of poor hydrolysis resistance, chalking, and high temperature of synthetic leather garments, and achieve the goal of improving grade and quality, increasing hydrolysis resistance, and improving service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

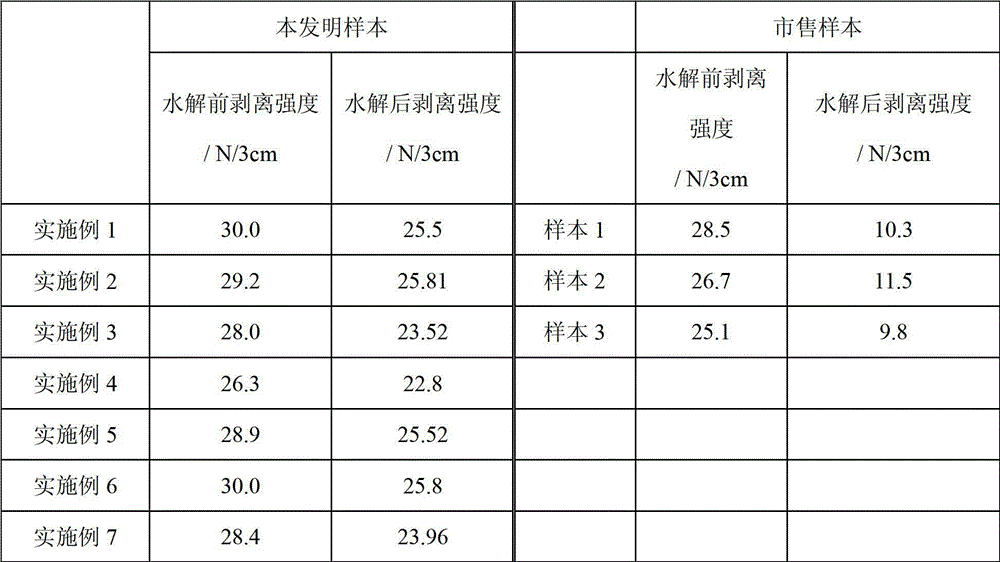

Examples

Embodiment 1

[0029] The hydrolysis-resistant polyurethane resin for garment synthetic leather is made of the following components in parts by weight:

[0030] 10 parts of 4,4-diphenylmethane diisocyanate, 15 parts of toluene diisocyanate;

[0031] 4 parts of polybutylene adipate with a molecular weight of 2500; 4 parts of polyethylene adipate with a molecular weight of 2500;

[0032] Molecular weight is 10 parts of polytetrahydrofuran ether diols and molecular weight is 10 parts of polypropylene oxide ether polyols of 2500;

[0033] 0.4 parts of ethylene glycol, 0.3 parts of butanediol and 0.3 parts of neopentyl glycol;

[0034] 1 part of disulfamic acid salt;

[0035] Additives include: 4 parts of neutralizer, any reasonable neutralizer can be selected, preferably, sodium hydroxide, potassium hydroxide, dimethylethanolamine, dimethyl sulfate or hydrochloric acid; 3 parts of defoamer, optional Any reasonable polyether-modified silicone compound, preferably BYK-020; 3 parts of thickener,...

Embodiment 2

[0045] The hydrolysis-resistant polyurethane resin for garment synthetic leather is made of the following components in parts by weight:

[0046] 15 parts of 4,4-diphenylmethane diisocyanate, 10 parts of toluene diisocyanate;

[0047] 4 parts of polybutylene adipate with a molecular weight of 2000; 6 parts of polyethylene adipate with a molecular weight of 2000;

[0048] 6 parts of polytetrahydrofuran ether diols and 14 parts of polyoxypropylene ether polyols of 2000 with a molecular weight of 2000;

[0049] 0.3 parts of ethylene glycol, 0.3 parts of butanediol and 0.3 parts of neopentyl glycol;

[0050] 5 parts of dimethylolpropionic acid;

[0051]Additives include: 3 parts of neutralizing agent, any reasonable neutralizing agent can be selected, preferably, sodium hydroxide, potassium hydroxide, dimethylethanolamine, dimethyl sulfate or hydrochloric acid; 3 parts of defoaming agent, optional Any reasonable polyether-modified silicone compound, preferably BYK-020; 4 parts ...

Embodiment 3

[0061] The hydrolysis-resistant polyurethane resin for garment synthetic leather is made of the following components in parts by weight:

[0062] 20 parts of 4,4-diphenylmethane diisocyanate;

[0063] 6 parts of polybutylene adipate with a molecular weight of 4000; 4 parts of polyethylene adipate with a molecular weight of 4000;

[0064] Molecular weight is 8 parts of polytetrahydrofuran ether diols and molecular weight is 12 parts of polyoxypropylene ether polyols of 4000;

[0065] 0.4 parts of ethylene glycol; 0.4 parts of butylene glycol;

[0066] 10 parts of dimethylolbutyric acid;

[0067] Additives include: 2.5 parts of neutralizer, any reasonable neutralizer can be selected, preferably, sodium hydroxide, potassium hydroxide, dimethylethanolamine, dimethyl sulfate or hydrochloric acid; 2.5 parts of defoamer, optional Any reasonable polyether-modified silicone compound, preferably BYK-020; 2.5 parts of thickener, any reasonable associative water-based polyurethane or a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com