Metal silicon-based nitrogen oxide fluorescent powder and preparation method thereof

A nitrogen oxide and phosphor technology, applied in the field of rare earth luminescent materials, can solve problems such as the condition of excellent light source, color temperature change, color temperature rise, etc., and achieve the advantages of industrialized large-scale production, improved luminous intensity and performance, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1 Preparation of Sr 0.98 Si 2 o 2 N 2 :0.02Eu 2+ Phosphor powder

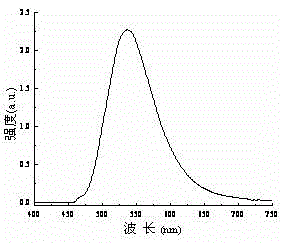

[0035] Weigh 4.3403g SrCO 3 (AR), 2.8056g Si 3 N 4 (purity>95%) and 0.1056g Eu 2 o 3 (purity>99.99%), after mixing, put it in a zirconia ball mill jar, add zirconia balls and an appropriate amount of ball milling medium, the total amount of the sample should not exceed 2 / 3 of the ball mill jar, and ball mill it on a planetary ball mill for 3 hours; The samples were put into a drying oven and dried at 100°C for 4 hours; the dried powder was placed in an atmosphere furnace and filled with N 2 / H 2 The mixed gas is circulated, the calcination temperature is 1300°C, and the calcination time is 5 hours; with the furnace cooling, the sample is taken out, ground and sieved, and the spectrum is tested as follows: figure 1 shown.

[0036] Such as figure 1 The fluorescent powder shown can be effectively excited by ultraviolet light, near ultraviolet light and blue light in the range of 250-5...

Embodiment 2

[0037] Example 2 Preparation of Sr 0.96 Si 2 o 2 N 2 :0.04Eu 2+ Phosphor powder

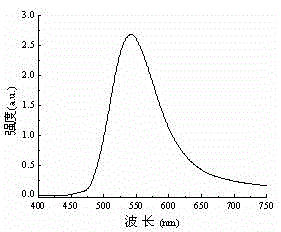

[0038] Weigh 4.2517g SrCO 3 (AR), 2.8056g Si 3 N 4 (purity>95%) and 0.2112g Eu 2 o 3 (purity>99.99%), after mixing, put it in a zirconia ball mill jar, add zirconia balls and an appropriate amount of ball milling medium, the total amount of the sample should not exceed 2 / 3 of the ball mill jar, and ball mill it on a drum mill for 3 hours; The samples were put into a drying oven and dried at 100°C for 4 hours; the dried powder was placed in an atmosphere furnace and filled with N 2 / H 2 The mixed gas is circulated, the calcination temperature is 1500°C, and the calcination time is 2 hours; with the furnace cooling, the sample is taken out, ground and sieved, and the spectrum is tested as follows: figure 2 shown.

[0039] Such as figure 2 The fluorescent powder shown can be effectively excited by ultraviolet light, near ultraviolet light and blue light in the range of 250-500nm to ...

Embodiment 3

[0040] Example 3 Preparation of Sr 0.98 Si 2 o 2 N 2 :0.02Eu 2+ Phosphor powder

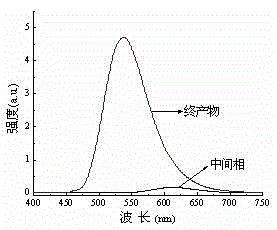

[0041] Step 1: Weigh 4.3403g SrCO 3 (AR), 0.1056g Eu 2 o 3 (purity>99.99%), put them in a zirconia ball mill jar after mixing, add zirconia balls and an appropriate amount of ball milling medium, the total amount of the sample should not exceed 2 / 3 of the ball mill jar, and ball mill for 3 hours on a planetary ball mill to make SrCO 3 and Eu 2 o 3 Mix well to form the primary mixture; put the ground primary mixture into a drying box and dry at 100°C for 4 hours; place the dried powder in an atmosphere furnace and fill it with N 2 / H 2 Mixed gas circulation, calcination temperature is 1000°C, calcination time is 6 hours; cool down with the furnace, take out the sample and grind it and sieve it with a 100-mesh standard inspection sieve, it is the mesophase silicate, and test the spectrum of the mesophase silicate ;

[0042] Step 2: Weigh 2.8056g Si 3 N 4 (purity>95%), then Si 3 N ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com