Aromatic hydrocarbon treatment process

A treatment process and aromatics technology, applied in the petroleum industry, refined hydrocarbon oil, etc., can solve the problems of clay deactivation, catalyst performance degradation, etc., and achieve the effect of short regeneration time, high regeneration degree and enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] As a neutral adsorbent, activated carbon generally has an adsorption capacity of 7% to 21%. Commercially available activated carbon was selected as the adsorbent in the experiment, and its performance parameters are shown in Table 1 below.

[0027] Table 1. Performance parameters of activated carbon

[0028]

[0029] Aromatics-containing raw materials are aromatics intermediate products from reforming units in the petrochemical industry (hereinafter referred to as feedstock oil), and their olefin content is less than 1%. The specific components are shown in Table 2 below.

[0030] Table 2. Main components of raw oil

[0031]

[0032] During the experiment, a bromine index tester was used to test the bromine index (Ye Hong, Tian Songbai. Analysis method of olefins in diesel oil. Changlian Technology, 2004,30(2):59-64). The bromine index of raw oil is around 900 mgBr / 100g oil.

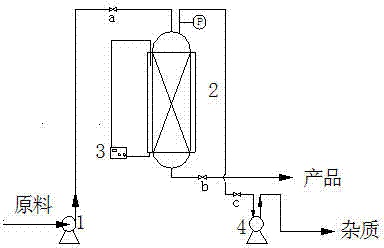

[0033] A single adsorption bed device is schematically shown in figure 1 . The spec...

Embodiment 2

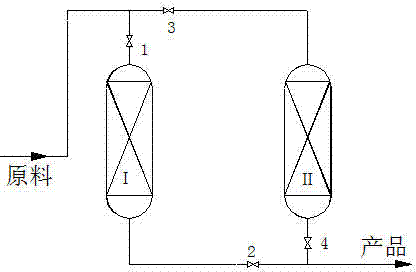

[0036] Sorbent and aromatic raw material are the same as in Example 1. The adsorption device consists of two single adsorption beds in Example 1, schematically shown in figure 2 . When valves 1 and 2 are opened and valves 3 and 4 are closed, the adsorption bed I will be adsorbed. When the bromine index of the outlet oil of adsorption bed I is higher than 20mgBr / 100g oil, valves 1 and 2 will be closed and valves 3 and 4 will be opened, and the adsorption bed will Ⅰ is regenerated, and the raw material enters the adsorption bed Ⅱ at the same time; similarly, when the bromine index of the outlet oil of the adsorption bed Ⅱ is higher than 20mgBr / 100g oil, the adsorption bed Ⅱ is regenerated, and the raw material enters the adsorption bed Ⅰ at the same time. The adsorption and regeneration conditions of the adsorption bed are also the same as in Example 1. The adsorption period of activated carbon is about 2 days, and it can continue to be used after regeneration. Compared with...

Embodiment 3

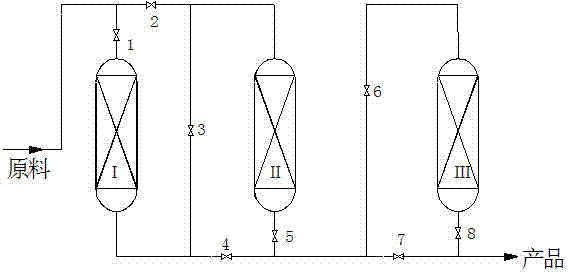

[0038] Sorbent and aromatic raw material are the same as in Example 1. In this example, three single adsorption beds I, II, and III in Example 1 are used for cyclic adsorption, in which two adsorption beds are adsorbed in series, and the other adsorption bed is regenerated, as shown in image 3 . The reason why two beds are operated in series is to ensure that the bromine index of the product is lower than 20mgBr / 100g oil, and it also prolongs the service life of the adsorbent, because the first bed can be used until the adsorbent is deactivated. Some olefins pass through the first bed into the second bed before total deactivation, and the slip-through olefins are absorbed by the second bed, leaving the product still within specification. When the bromine index of the oil at the outlet of the adsorption bed exceeds 300 mgBr / 100g oil, we consider that the adsorbent has been deactivated, and the adsorption can be terminated and regeneration can be carried out. Such as image ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com