Low-chrome refractory material RH refining furnace and building method thereof

A refractory material and refining furnace technology, applied in the field of refining equipment outside the steel furnace, can solve the problems of repairing and replacing a large amount of time, high construction costs, and environmental pollution of magnesia-chrome bricks, so as to reduce damage to the human body and the environment and improve the use of Efficiency and the effect of reducing the cost of masonry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

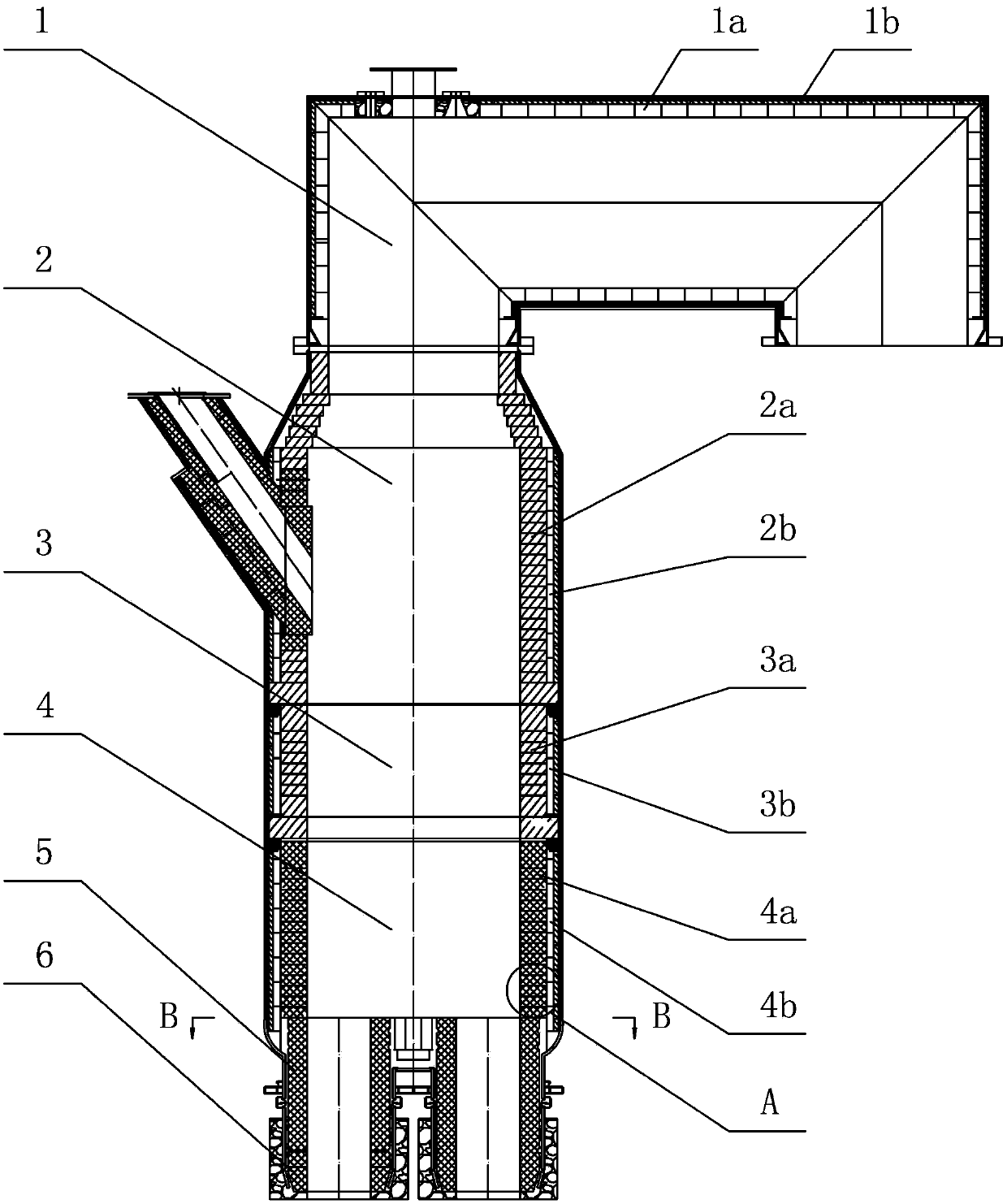

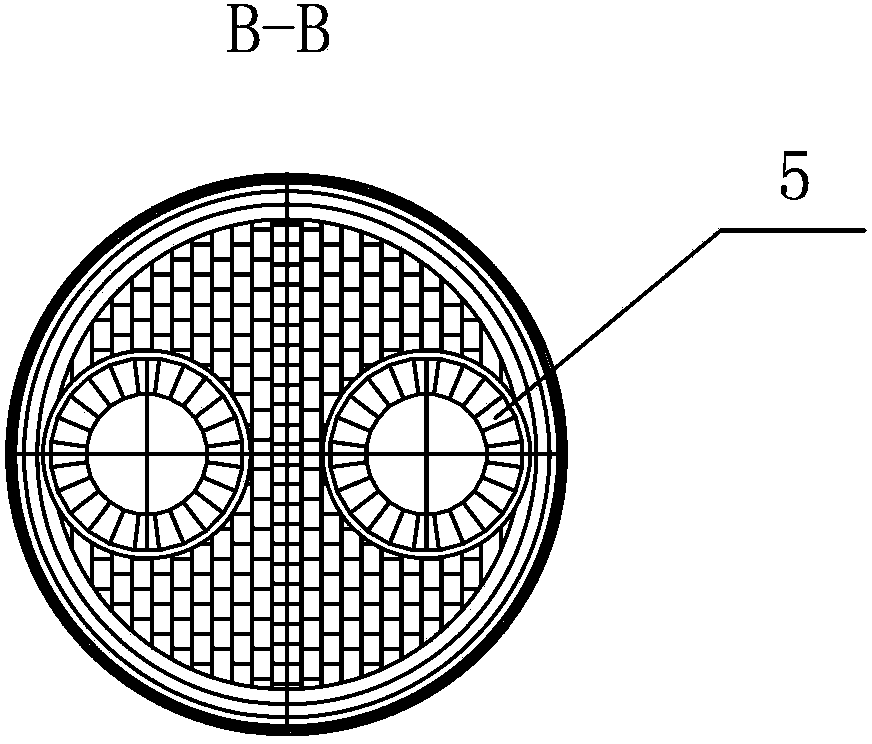

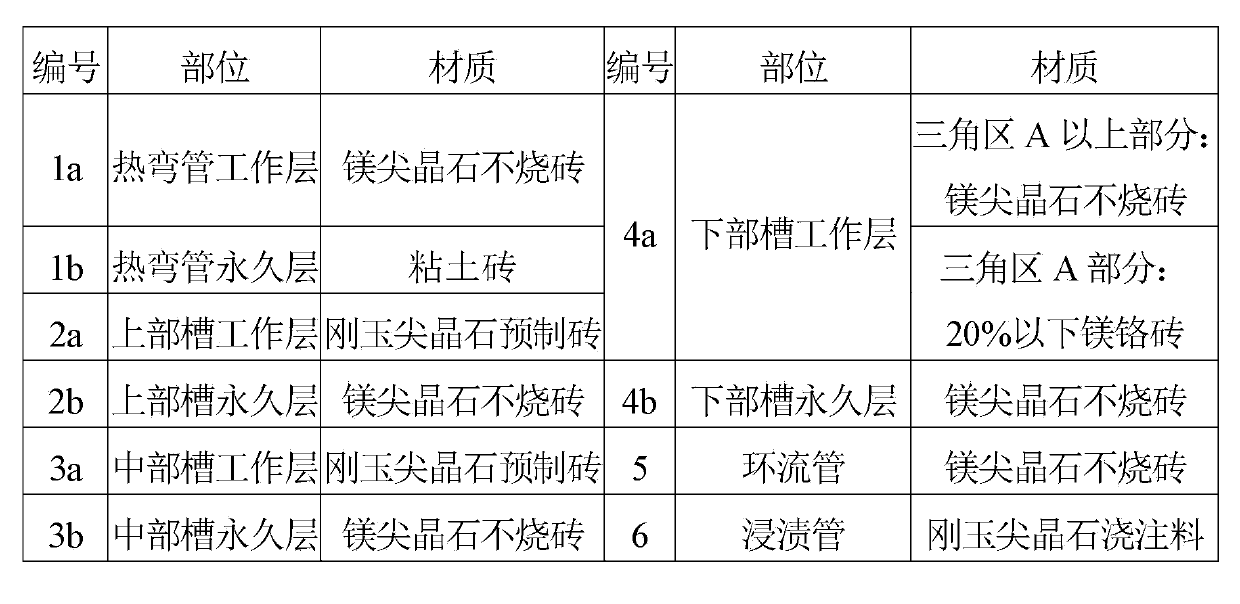

[0046] The RH refining furnace of embodiment 1 is as Figure 1~2 As shown, it is mainly composed of a hot bend pipe 1, an upper tank 2, a middle tank 3, a lower tank 4, a circulating pipe 5 and a dipping pipe 6 arranged sequentially from top to bottom. Among them, the hot bending pipe 1 has the hot bending pipe working layer 1a and the hot bending pipe permanent layer 1b, the upper groove 2 has the upper groove working layer 2a and the upper groove permanent layer 2b, and the middle groove 3 has the middle groove working layer 3a and the middle groove permanent layer 2b. Layer 3b, lower tank 4 has a lower tank working layer 4a and a lower tank permanent layer 4b. The refractory materials and masonry techniques used in the above parts are as follows:

[0047] The hot bending pipe working layer 1a, the upper groove permanent layer 2b, the middle groove permanent layer 3b and the lower groove permanent layer 4b are all made of magnesia spinel unfired bricks, and the hot bending ...

Embodiment 2

[0063] The composition and masonry method of the RH refining furnace of embodiment 2 are basically the same as those of embodiment 1, and the existing differences are as follows:

[0064] Its corundum spinel prefabricated brick or castable is composed of the following raw materials in weight ratio:

[0065] Tabular alumina with a particle size of 0.088~12mm accounts for 65%;

[0066] Magnesium-aluminum spinel with a particle size of ≤0.074mm accounts for 30%;

[0067] Cement with particle size ≤0.088mm accounts for 2%;

[0068] Metal aluminum powder with particle size ≤0.088mm accounts for 1%;

[0069] Polypropylene fiber with a length of 2~10mm accounts for 1%;

[0070] Sodium hexametaphosphate accounted for 1%.

[0071] The specific material usage of embodiment 2 is shown in table 2.

[0072] Table 2 Table of materials used for each component of the RH refining furnace in Example 2

[0073]

Embodiment 3

[0075] The RH refining furnace composition and masonry method of embodiment 3 are also basically the same as embodiment 1, and the differences are as follows:

[0076] Its corundum spinel prefabricated brick or castable is composed of the following raw materials in weight ratio:

[0077] White corundum with a particle size of 0.088~12mm accounts for 85%;

[0078] Fused magnesia with particle size ≤0.074mm accounted for 30%;

[0079] Cement with particle size ≤0.088mm accounted for 3.9%;

[0080] Metal aluminum powder with particle size ≤0.088mm accounts for 0.5%;

[0081] Polyvinyl alcohol fibers with a length of 2~10mm account for 0.5%;

[0082] Sodium tripolyphosphate accounted for 0.1%.

[0083] The specific material usage of embodiment 3 is shown in table 3.

[0084] Table 3 Material usage list of each component of the RH refining furnace in Example 3

[0085]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com