Environment-friendly and flame-retardant glass fibre reinforced PP/PA1010 alloy material with high CTI (comparative tracking index) valve and high GWIT (glow wire ignition temperature) value and preparation method thereof

An alloy material and environmentally friendly technology, applied in the field of PP/PA1010 alloy material and its preparation, to achieve the effects of improving impact performance, reducing friction coefficient and improving slipperiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Example 1 Preparation of PP / PA1010 alloy material of the present invention (1)

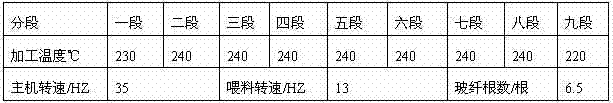

[0061] Weigh raw materials by weight percentage: PP 25%, PA1010 (intrinsic viscosity: 2.8dl / g) 25.1%, compound flame retardant 12%, antimony trioxide 4%, alkali-free glass treated with silane coupling agent Fiber 30%, maleic anhydride grafted PP 3%, antioxidant 1330 0.4%, iron oxide 0.5%; put the weighed raw materials into a high-mixer and mix for 5 minutes, and discharge; extrude with a twin-screw extruder For granulation, the processing temperature is 220-240°C, the screw speed is 35HZ, and the specific processing conditions are shown in the table below.

[0062]

Embodiment 2

[0063] Example 2 Preparation of PP / PA1010 alloy material of the present invention (2)

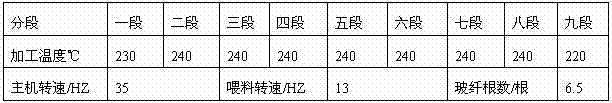

[0064] Weigh raw materials by weight percentage: PP 25%, PA1010 (intrinsic viscosity: 2.8dl / g) 23%, compound flame retardant 12%, antimony trioxide 4%, alkali-free glass treated with silane coupling agent Fiber 30%, maleic anhydride grafted PP 5%, antioxidant 1330 0.4%, iron oxide 0.6%; put the weighed raw materials into a high-mixer and mix for 2 minutes, and discharge; extrude with a twin-screw extruder For granulation, the processing temperature is 220-240°C, the screw speed is 35HZ, and the specific processing conditions are shown in the table below.

[0065]

Embodiment 3

[0066] Example 3 Preparation of PP / PA1010 alloy material of the present invention (3)

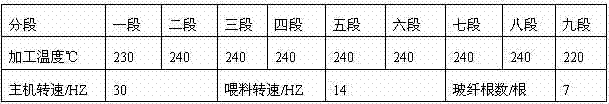

[0067] Weigh raw materials by weight percentage: PP 23%, PA1010 (intrinsic viscosity: 2.8dl / g) 22%, compound flame retardant 20%, antimony trioxide 4.3%, alkali-free glass treated with silane coupling agent Fiber 20%, maleic anhydride grafted PP 10%, antioxidant 1330 0.1%, iron oxide 0.6%; put the weighed raw materials into a high-mixer and mix for 2 minutes, and discharge; extrude with a twin-screw extruder For granulation, the processing temperature is 220-240°C, the screw speed is 30HZ, and the specific processing conditions are shown in the table below.

[0068]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com