Method for preparing biological aviation kerosene by using swell-cooked dirty oil

A technology for aviation kerosene and waste oil, which is applied to the preparation of biological raw materials, liquid hydrocarbon mixtures, and the petroleum industry, and can solve problems such as harsh reaction conditions, low production safety, combustion or explosion, etc., so as to increase yield and avoid Contamination, fully reactive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

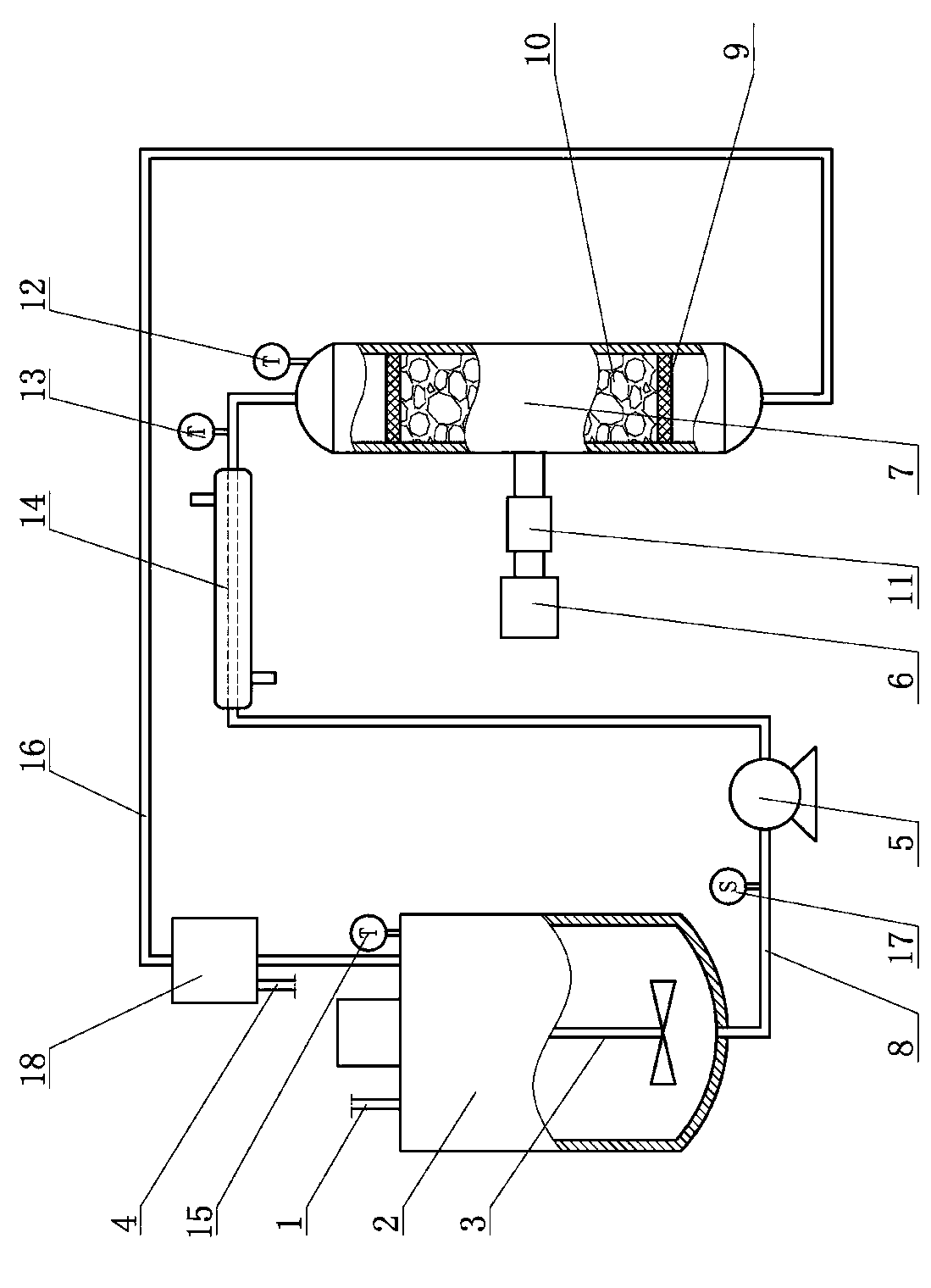

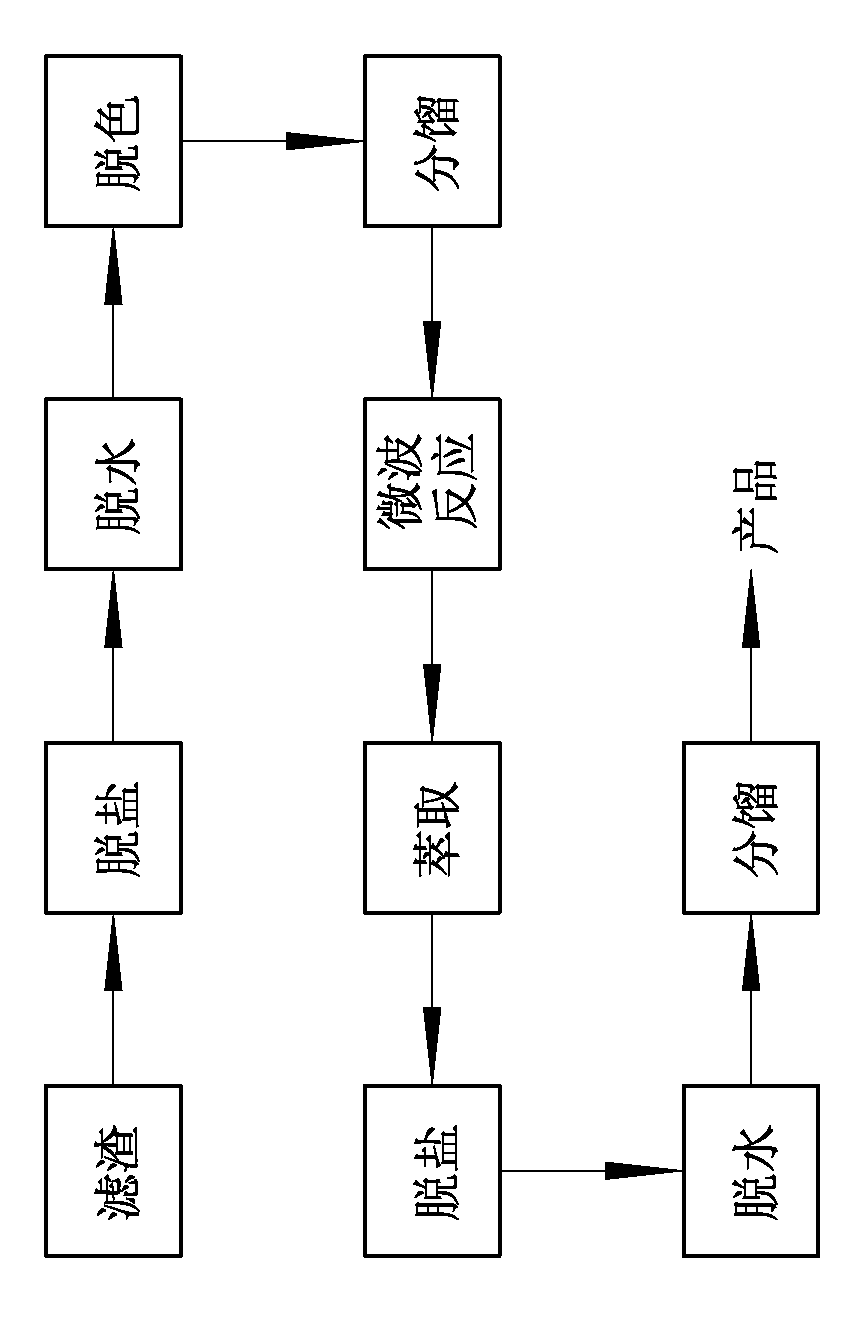

Image

Examples

Embodiment 1

[0020] The specific steps are:

[0021] ①Pretreatment: Heat 160kg of waste oil to boiling, keep it warm for 15 minutes, cool to room temperature, filter to remove impurities, then heat the waste oil after the filter residue to 80°C, slowly add 22.9kg of 25% partial weight under stirring Sodium aluminate solution, keep warm for 2 hours until completely separated, remove the water layer and flocs; then add 90kg of water to the waste oil, heat to 50°C, keep stirring for 15 minutes, stand until completely separated, remove the water layer , to obtain salt-free waste oil, then add 8 kg of anhydrous magnesium sulfate to the salt-free waste oil, let it stand for 2 hours, filter and remove the magnesium sulfate solid to obtain anhydrous waste oil, and finally add 3.2 kg of activated clay to the anhydrous waste oil , heated to 110°C, kept standing for 1 hour, filtered to remove activated clay, and obtained 150.4kg of pretreated waste oil;

[0022] ②Add the pretreated waste oil obtaine...

Embodiment 2

[0026] The specific implementation steps are:

[0027] ①Pretreatment: Heat 100kg of waste oil to boiling, keep it warm for 20 minutes, cool to room temperature, filter to remove impurities, then heat the waste oil after filtering to 90°C, and slowly add 28.6kg of Sodium aluminate solution, keep warm for 3 hours until completely separated, remove the water layer and flocs; then add 110kg of water to the waste oil, heat to 60 ° C, keep stirring for 20 minutes, stand until completely separated, remove the water layer , to obtain salt-free waste oil, then add 4kg of anhydrous magnesium sulfate to the salt-free waste oil, let it stand for 2.5h, filter and remove the magnesium sulfate solid to obtain anhydrous waste oil, and finally add 1.67kg of active Clay clay, heated to 120°C, heat preservation and standing for 1.5h, filtered to remove activated clay, to obtain 94.3kg of pretreated waste oil;

[0028] ② Add the pretreated waste oil obtained in step ① into the fractionation towe...

Embodiment 3

[0032] The specific implementation steps are:

[0033] ①Pretreatment: Heat 200kg of waste oil to boiling, keep it warm for 18 minutes, cool to room temperature, filter to remove impurities, then heat the waste oil after the filter residue to 85°C, slowly add 42.9kg of 25% partial weight under stirring Sodium aluminate solution, heat preservation and stand for 2.5 hours until completely separated, remove the water layer and flocs; then add 176kg of water to the waste oil, heat to 55 ° C, keep stirring for 18 minutes, stand until completely separated, remove water Layer to obtain salt-free waste oil, then add 8.7kg anhydrous magnesium sulfate to the salt-free waste oil, let it stand for 2.3h, filter and remove the magnesium sulfate solid to obtain anhydrous waste oil, and finally add 3.64 kg to the anhydrous waste oil kg of activated clay, heated to 115°C, left standing for 1.3h at heat preservation, filtered to remove activated clay, and obtained 192.6kg of pretreated waste oil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com