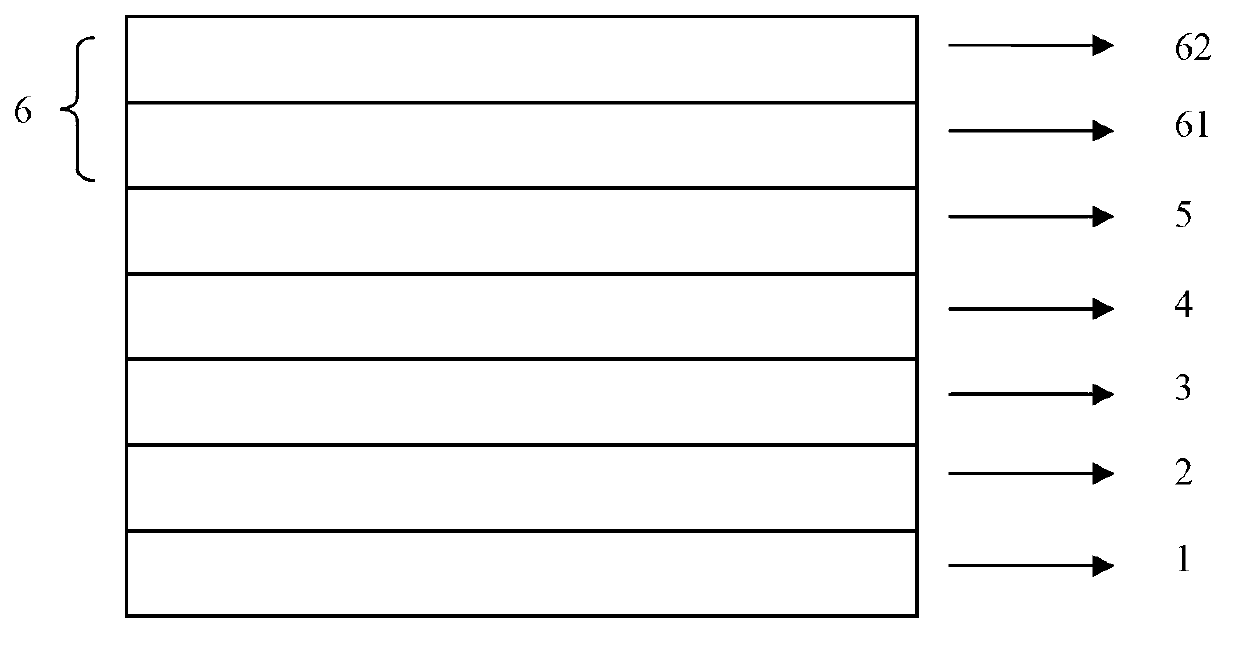

One-dimensional photonic crystal back reflecting mirror based inverted semitransparent polymer solar cell and preparation method thereof

A technology of dimensional photonic crystals and solar cells, applied in the field of polymer solar cells, can solve problems such as expensive production equipment, restrictions on large-scale civilian commercialization, complex production processes, etc., and achieve good electrical conductivity, high transmittance, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1. Use acetone, ethanol and deionized water in sequence to ultrasonically clean the transparent FTO conductive glass. After cleaning, dry it with dry nitrogen and put it in a petri dish for later use;

[0034] 2. At room temperature, drop the mixed solution of 20ml ethanol, 5ml deionized water, and 1ml hydrochloric acid with a concentration of 0.2mol / l into the solution containing 5ml tetrabutyl titanate, 40ml ethanol, and 3ml acetylacetone , and accompanied by vigorous stirring for 1 hour, left to age for 48 hours, and then obtained TiO 2 Sol.

[0035] 3. Place the configured TiO 2 The sol was spin-coated on ITO glass at a speed of 1000rpm and spin-coated for 20s, and sintered in a muffle furnace at 440°C for 1.5 hours. After sintering, nc-TiO was formed on the ITO glass. 2 layer with a thickness of about 40nm;

[0036] 4. Spin-coat the chlorobenzene solution of P3HT and PCBM with a mass ratio of 1:0.9 and a uniform (stirred) concentration of 10 mg / ml on the ITO / nc-...

Embodiment 2

[0041] 1. Use acetone, ethanol and deionized water in sequence to ultrasonically clean the transparent FTO conductive glass. After cleaning, dry it with dry nitrogen and put it in a petri dish for later use;

[0042] 2. At room temperature, drop the mixed solution of 40ml ethanol, 15ml deionized water, and 3ml hydrochloric acid with a concentration of 0.3mol / l into the solution containing 20ml tetrabutyl titanate, 80ml ethanol, and 10ml acetylacetone , and accompanied by vigorous stirring for 5 hours, left to age for 48h, and then obtained TiO 2 Sol.

[0043] 3. Place the configured TiO 2 The sol was spin-coated on ITO glass at a speed of 5000rpm and spin-coated for 20s, and sintered in a muffle furnace at 460°C for 3 hours. After sintering, nc-TiO was formed on the ITO glass. 2 layer, the thickness is 15nm;

[0044] 4. Spin-coat the chlorobenzene solution of P3HT and PCBM with a mass ratio of 1:1 and a uniform concentration of 20mg / ml on the ITO / nc-TiO at a speed of 1500rp...

Embodiment 3

[0049] 1. Use acetone, ethanol and deionized water in sequence to ultrasonically clean the transparent FTO conductive glass. After cleaning, dry it with dry nitrogen and put it in a petri dish for later use;

[0050] 2. At room temperature, drop a mixed solution of 30ml ethanol, 10ml deionized water, and 2ml hydrochloric acid with a concentration of 0.28mol / l into a solution containing 10ml tetrabutyl titanate, 60ml ethanol, and 5ml acetylacetone , and accompanied by vigorous stirring for 3 hours, left to age for 48h, and then obtained TiO 2 Sol.

[0051] 3. Place the configured TiO 2 The sol was spin-coated on ITO glass at a speed of 3000rpm and spin-coated for 20s, and sintered in a muffle furnace at 450°C for 2 hours. After sintering, nc-TiO was formed on the ITO glass. 2 layer, the thickness is 25nm;

[0052] 4. Spin-coat the chlorobenzene solution of P3HT and PCBM with a mass ratio of 1:0.8 and a uniform concentration of 15mg / ml on the ITO / nc-TiO at a speed of 1200rpm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com