Method for making dried velvet bean pod

A bean pod and drying technology, applied in the direction of dehydration preservation of fruits/vegetables, heating preservation of fruits/vegetables, etc., can solve the problems of uneven quality, poor economic benefits, poor sanitary conditions, etc., to shorten the drying time and the degree of browning Low, to avoid the effect of quality degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

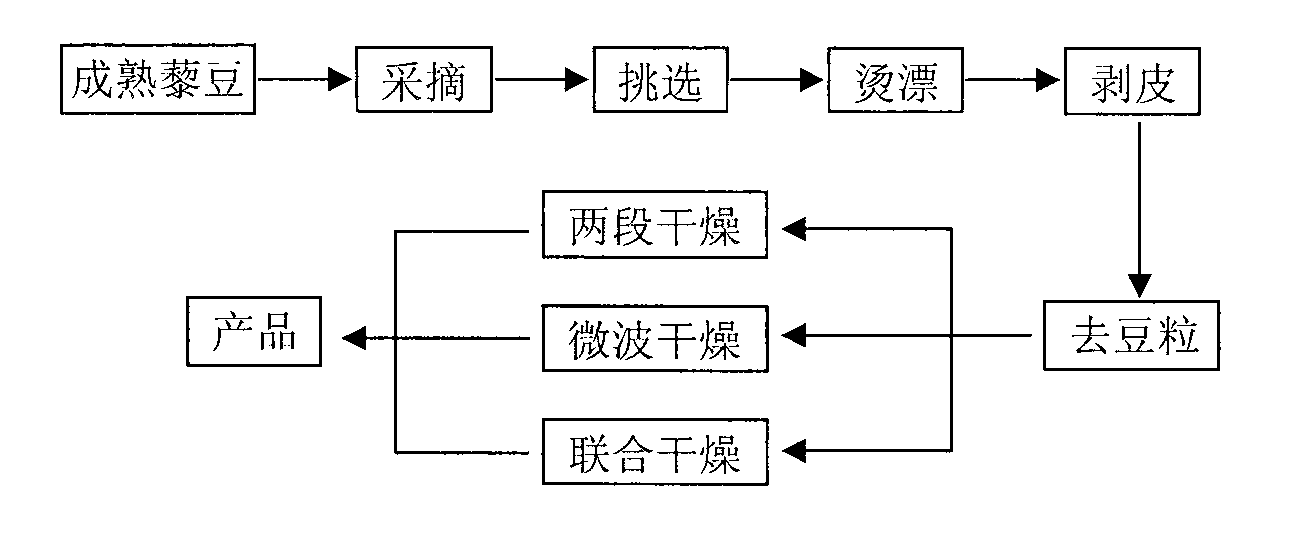

[0025] The implementation steps adopted in this embodiment are as follows:

[0026] After the quinoa beans are mature, cut off the whole bunch of quinoa beans with scissors, select the whole bunch of quinoa beans with the same maturity and no mechanical damage, cut them off one by one, take 5kg of quinoa beans for later use; put the quinoa beans in clean water at 100°C Medium blanching for 15 minutes; after blanching, remove the quinoa beans immediately, peel off the skin of the quinoa pods while hot at 50-100°C, break apart the quinoa beans, remove the bean grains, and get the quinoa bean pods; The quinoa pods are dehydrated and dried.

[0027] Two-stage hot air drying, laying the finished quinoa pods on the stainless steel grid, after the automatic hot air drying oven reaches the set parameters, move the grid into the automatic hot air drying oven for drying, the drying conditions are: the first stage The drying temperature is 70°C, the relative humidity is 35%, the wind sp...

Embodiment 2

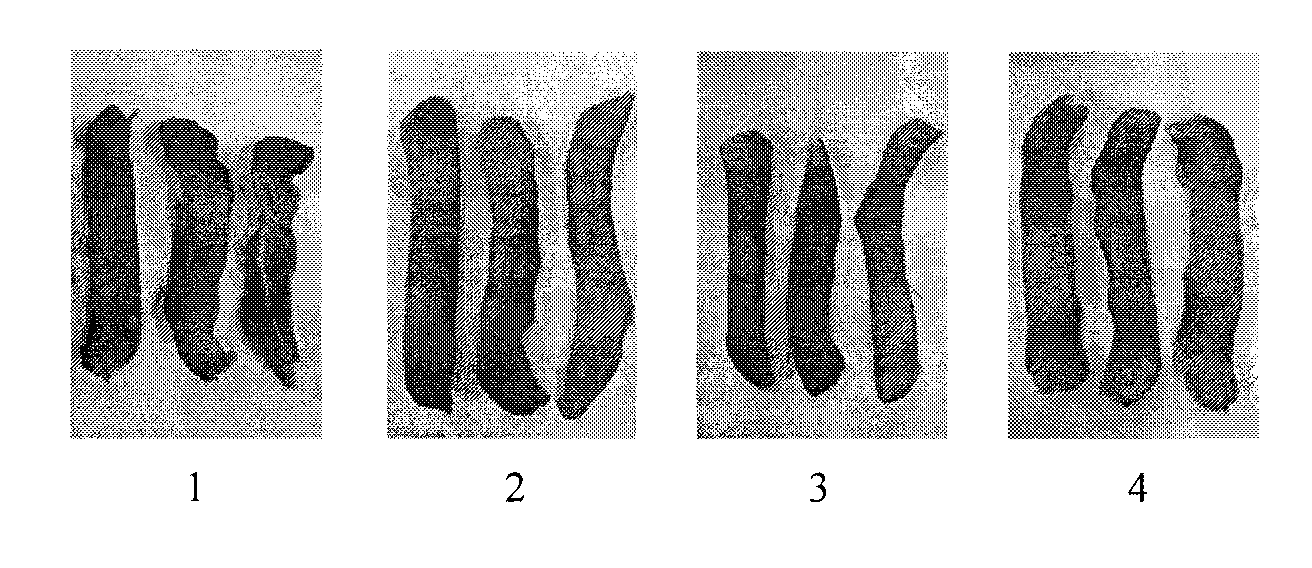

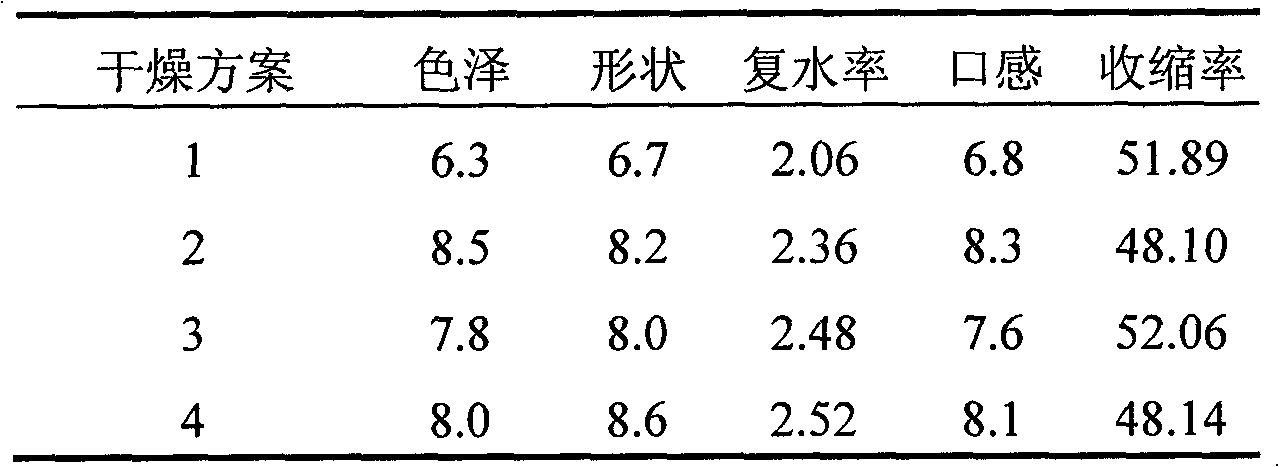

[0031] Examples of the sensory quality of dried quinoa pods made under different hot air drying conditions in Example 2

[0032] According to the method described in embodiment 1, make dried quinoa pods with different drying schemes;

[0033] Scheme 1: Constant temperature and humidity, temperature 80°C, relative humidity 55%, wind speed 2m / s;

[0034] Scheme 2: The first stage of drying temperature is 70°C, relative humidity of 35%, wind speed of 2m / s, drying time of 60min, the second stage of drying temperature of 70°C, relative humidity of 25%, and wind speed of 2m / s;

[0035] Scheme 3: The first stage drying temperature is 80°C, relative humidity is 45%, wind speed is 2m / s, drying time is 60min, the second stage is drying temperature is 60°C, relative humidity is 25%, wind speed is 2m / s;

[0036] Scheme 4: The first stage drying temperature is 80°C, relative humidity is 55%, wind speed is 2m / s, drying time is 30min, the second stage is drying temperature is 80°C, relative...

Embodiment 3

[0046] Examples of the nutritional quality of dried quinoa pods made in different blanching modes in Example 3

[0047] Use different methods for blanching, method 1 is blanching with clean water at 100°C for 15 minutes, method 2 is blanching with clean water at 100°C for 25 minutes, method 3 is blanching with color protection solution (0.1% citric acid) at 100°C for 15 minutes, method 4 is color protection liquid (0.1% citric acid) 100 ℃ blanching 25min, control group is not blanching; According to the method of embodiment 1, adopt two sections of hot air drying to make dried quinoa pods, compare the nutrition of dried quinoa pods made by different blanching methods Quality, the measured indexes are all calculated on a dry basis (DW), and the results are shown in Table 2.

[0048] As can be seen from Table 2, compared with the control group, the contents of soluble sugar, vitamin C, free amino acid and levodopa in the dried quinoa pods obtained after blanching were lower, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com