Air clay and preparation method thereof

A technology of clay and air, applied in the field of clay, can solve the problems of unstable chemical properties, easy breeding of bacteria, and unguaranteed safety, and achieve the effects of preventing denaturation, preventing dry cracking, and high-performance antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

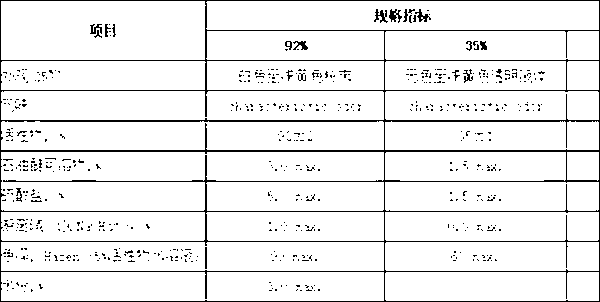

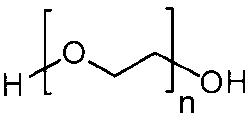

[0040] An air clay made of six components including quartz micropowder, pharmaceutical grade shell powder, polyethylene oxide, sodium α-olefin sulfonate, glycerin and sorbitol, the mass content of each component being quartz micropowder: 45 %, pharmaceutical grade shell powder: 25%, polyethylene oxide: 6%~8%, sodium alpha olefin sulfonate: 3%~4%, glycerin: 8%~10%, sorbitol: 8%~10%, The sum of the components of the air clay is 100%. Since polyethylene oxide, sodium α-olefin sulfonate, glycerin and sorbitol are used as additives, their values can be taken within the range.

Embodiment 2

[0042] An air clay made of six components: quartz micropowder, pharmaceutical grade shell powder, polyethylene oxide, sodium alpha olefin sulfonate, glycerin and sorbitol, the mass content of each component being quartz micropowder: 50 %, pharmaceutical grade shell powder: 40%, polyethylene oxide: 6%~8%, sodium alpha olefin sulfonate: 3%~4%, glycerin: 8%~10%, sorbitol: 8%~10%, The sum of the components of the air clay is 100%. Since polyethylene oxide, sodium α-olefin sulfonate, glycerin and sorbitol are used as additives, their values can be taken within the range.

[0043] Referring to the softness, feel and stretching effect of the final product, and based on the degree of foaming, the best numerical sampling is obtained:

Embodiment 3

[0045] An air clay made from 6 components including quartz micropowder, pharmaceutical grade shell powder, polyethylene oxide, sodium α-olefin sulfonate, glycerin and sorbitol, the mass content of each component being quartz micropowder: 48 %, pharmaceutical grade shell powder: 26%, polyethylene oxide: 6%~8%, sodium alpha olefin sulfonate: 3%~4%, glycerin: 8%~10%, sorbitol: 8%~10%, The sum of the components of the air clay is 100%. Since polyethylene oxide, sodium α-olefin sulfonate, glycerin and sorbitol are used as additives, their values can be taken within the range.

[0046] If the value of the additive needs to be further limited, the following values can be used:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com