Organic acid plant soil conditioner and preparation method thereof

A technology of soil conditioner and organic acid, which is applied in the field of organic acid plant soil conditioner and its preparation, can solve the problems of few yellow water utilization methods and low utilization rate, improve salinity and alkalinity, crop root environment, and improve soil Physical properties, effect of alleviating salinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

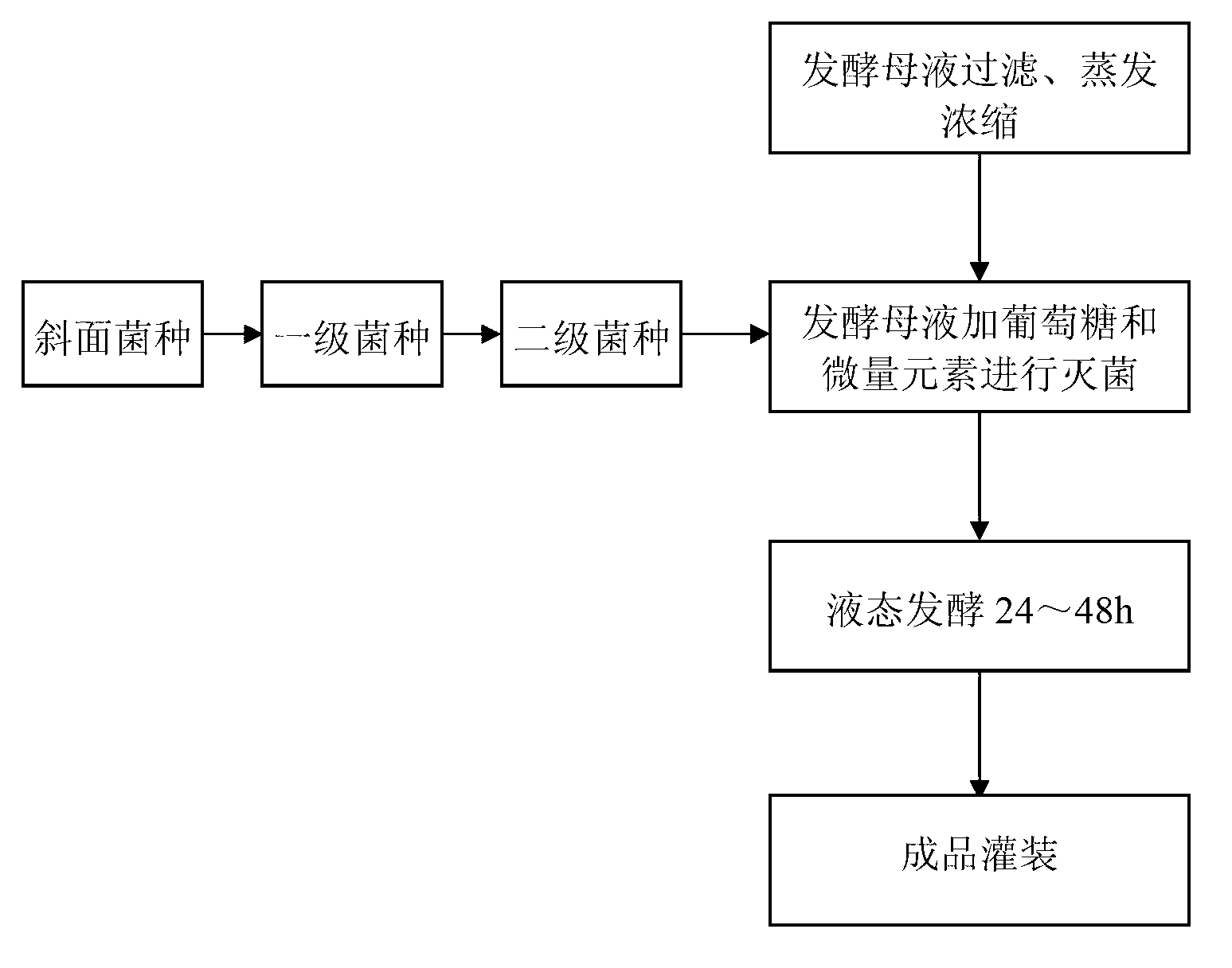

[0056] see figure 1 , prepare the organic acid plant soil conditioner of the present embodiment according to the following method:

[0057] 1. Weigh 1000L of yellow water, a by-product of liquor fermentation, and filter it with a multi-bag filter to remove larger impurities. Then the fermented yeast liquid is evaporated and concentrated into a liquid with a total solid content of 15% by an evaporation and concentration tank.

[0058] 2. After the treatment of the yellow water, the glucose, (NH 4 ) 2 SO 4 、KH 2 PO 4 , MgSO 4 ·7H 2 O, MnSO 4 ·H 2 O, NaCl and CaCO 3 Add it to the fermented yeast liquid at a weight ratio of 1%, 1%, 0.02%, 0.02%, 0.005%, 0.02% and 2%, respectively, and then cook and sterilize it at 121°C and 0.11MPa for 30min.

[0059] 3. Rhodopseudomonas palustris, Pseudomonas fluorescens, Azotobacter chroococcum, Bacillus megaterium and Bacillus mucilaginosus Bacterial enrichment was carried out according to the following methods:

[0060] (1) Rhod...

Embodiment 2

[0092] see figure 1 , prepare the organic acid plant soil conditioner of the present embodiment according to the following method:

[0093] 1. Weigh 1000L of yellow water, a by-product of liquor fermentation, and filter it with a multi-bag filter to remove larger impurities. Then the fermented yeast liquid is evaporated and concentrated into a liquid with a total solids content of 20% through an evaporation and concentration tank.

[0094] 2. After the treatment of the yellow water, the glucose, (NH 4 ) 2 SO 4 、KH 2 PO 4 , MgSO 4 ·7H 2 O, MnSO 4 ·H 2 O, NaCl and CaCO 3 Add them to the fermented yeast liquid at a weight ratio of 1.5%, 0.5%, 0.01%, 0.01%, 0.002%, 0.01% and 1.5%, respectively, and then cook and sterilize at 121°C and 0.11MPa for 30min.

[0095] 3. Rhodopseudomonas palustris, Pseudomonas florescens, Azotobacter chroococcum, Bacillus megaterium and Bacillus mucilaginosus Bacterial enrichment culture was carried out according to the method described in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com