Preparation method of polypyrrole/graphene sheet/nickel oxide nano composite conductive material

A graphene flake and nanocomposite technology, which is applied in the field of composite materials, can solve the problems of polypyrrole, such as brittle texture, infusibility, insolubility, and non-processability, so as to improve the electrical conductivity and solve the effect of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

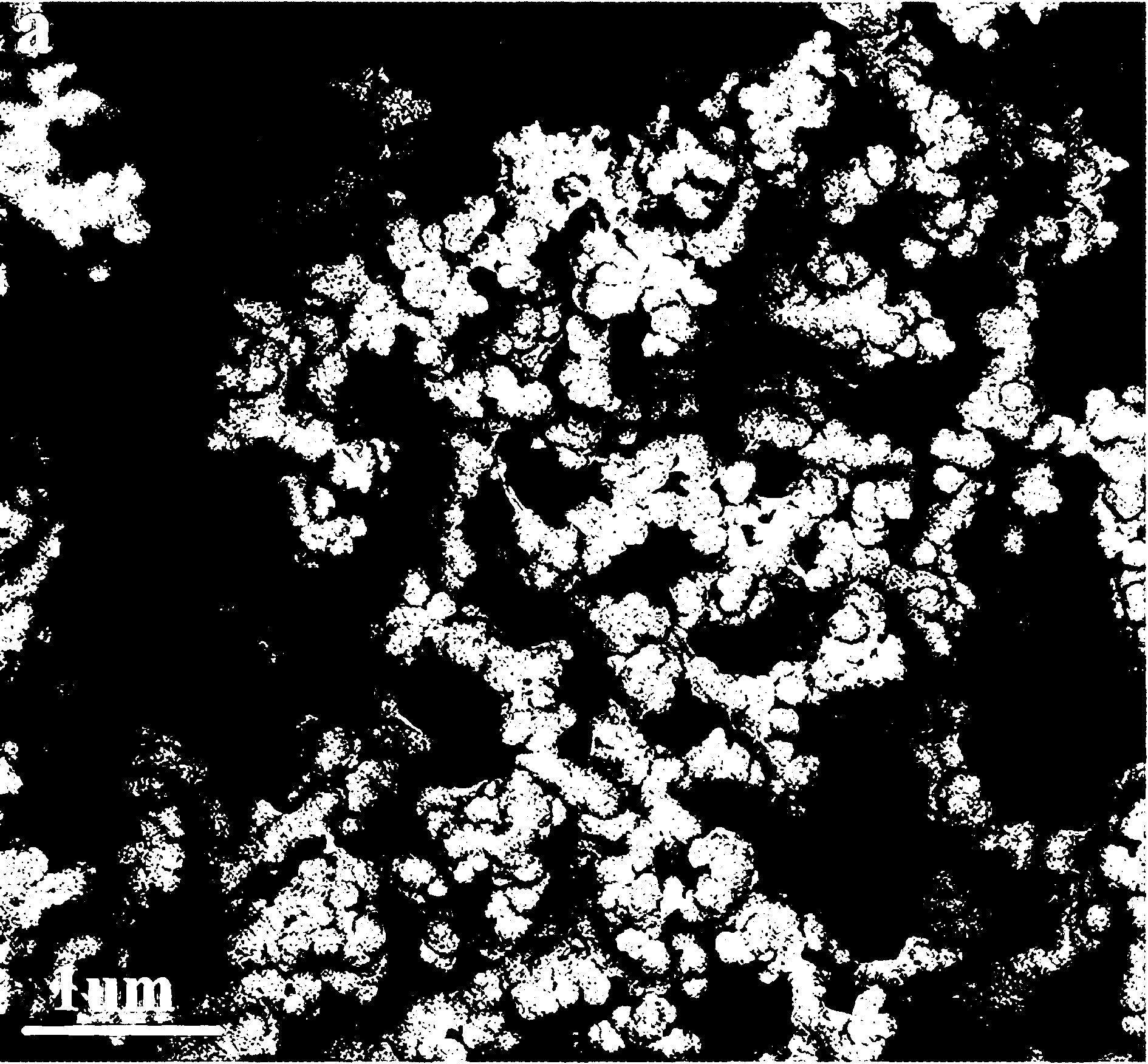

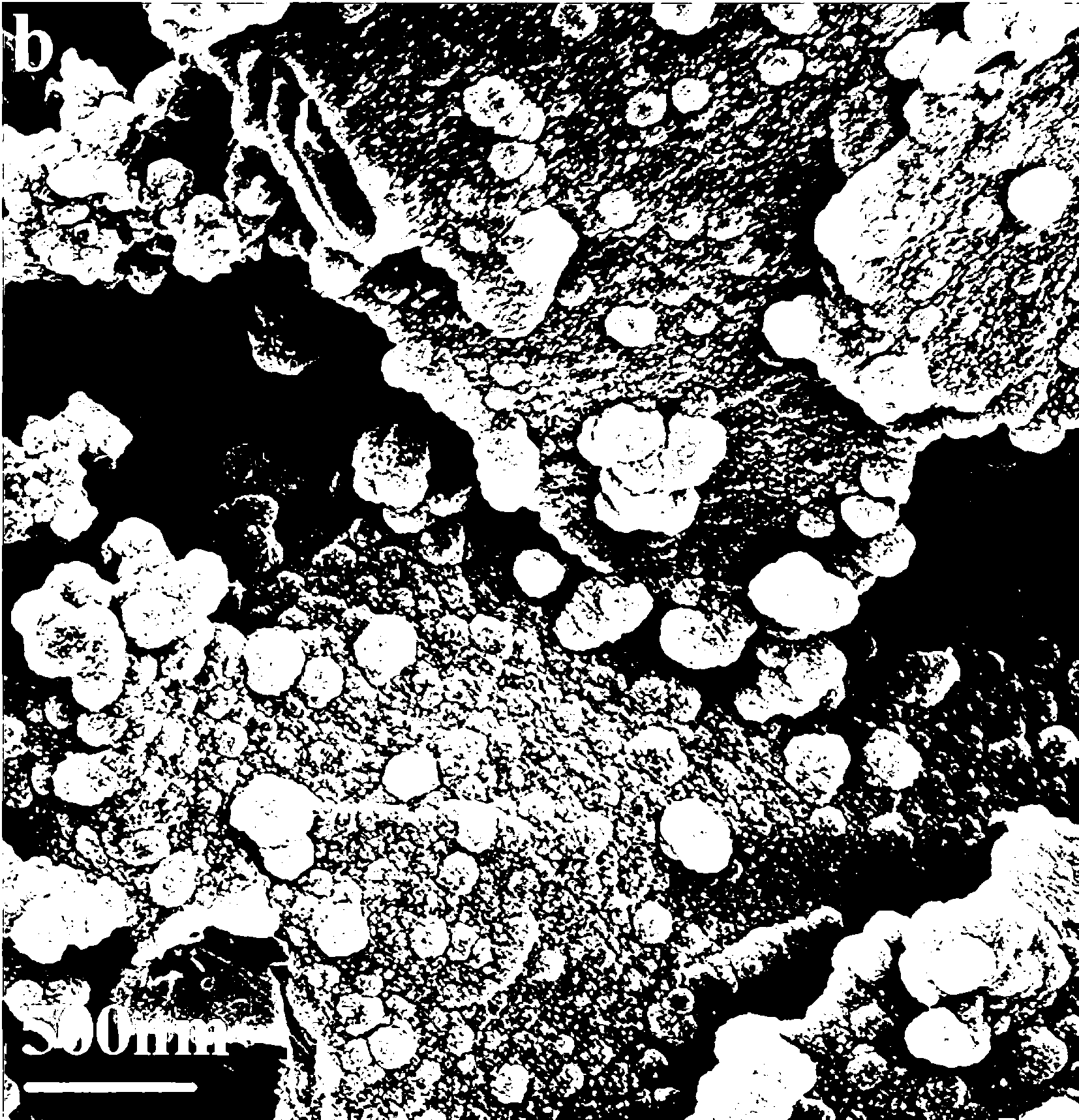

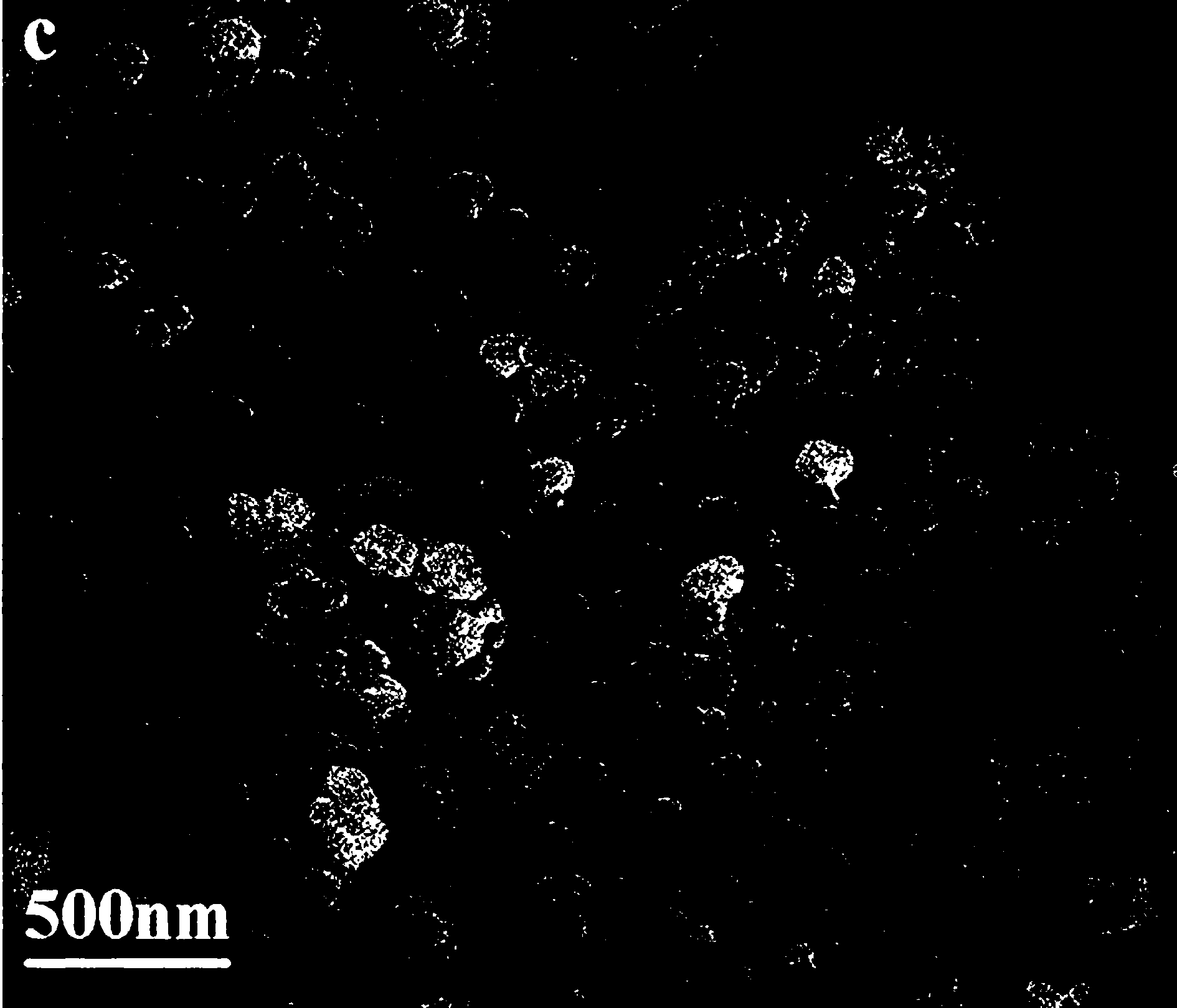

Image

Examples

Embodiment 1

[0031] ① Preparation of graphene flakes (GNS): Weigh 1 g of 200-mesh expandable graphite, place it in a muffle furnace, and expand it at a temperature of 950-1050°C for 10-15 seconds to obtain expanded graphite. Then use o-dichlorobenzene as a solvent, ultrasonically peel the expanded graphite for 3~4 hours, filter, wash, and dry to obtain GNS.

[0032] ②Preparation of nano-NiO: Add 50mL 0.2mol / L NiSO in a three-necked flask 4 ·6H 2 O, heat up to 70~80°C under ultrasonic conditions; adjust the pH value to about 10~12 with 0.4mol / L KOH solution, continue the ultrasonic reaction for 3~5h; cool for 6~12h, centrifuge, and wash repeatedly with distilled water until there is no SO 4 2- (with BaCl 2 inspection), finally washed with absolute ethanol, dried for 24 hours, ground, and then calcined at 350°C for 1~2 hours to obtain NiO with a particle size of 1~3nm.

[0033] ③Preparation of PPy / GNS / NiO: Take 0.015g GNS, 0.05 g NiO, 0.5g pyrrole monomer and 1 ml polyethylene glycol-400...

Embodiment 2

[0036] The preparation of nano-GNS and nano-NiO is the same as in Example 1.

[0037] ③Preparation of PPy / GNS / NiO: Take 0.016g GNS, 0.1 g NiO, 0.5g pyrrole monomer and 1 ml polyethylene glycol-400 in the reactor, add 6~10mL absolute ethanol, and ultrasonically disperse it evenly; Under ice bath conditions, add 0.4g p-toluenesulfonic acid, continue ultrasonic dispersion for 5min; add 50mL 0.34mol / L FeCl 3 solution, ultrasonically reacted for 2 to 4 hours, stood overnight, filtered with suction, washed until the filtrate was colorless, and dried to obtain a PPy / GNS / NiO conductive composite material.

[0038] The conductivity of the PPy / GNS / NiO conductive composite is 14.49 S / cm.

Embodiment 3

[0040] The preparation of nano-GNS and nano-NiO is the same as in Example 1.

[0041] Preparation of PPy / GNS / NiO: Take 0.028g GNS, 0.5g NiO, 0.5g pyrrole monomer and 1ml polyethylene glycol-400 in a reactor, add 6~10mL absolute ethanol, and ultrasonically disperse it evenly; Under the condition of ice bath, add 0.4g p-toluenesulfonic acid, ultrasonically disperse for 8min; add 50mL 0.34mol / L FeCl 3 solution, ultrasonically reacted for 2 to 4 hours, stood overnight, filtered with suction, washed until the filtrate was colorless, and dried to obtain a PPy / GNS / NiO conductive composite material.

[0042] The conductivity of the PPy / GNS / NiO conductive composite is 24.39 S / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com