Special light-failure-resistant flour blending fluorescent glue for LED (Light-emitting Diode) white light

A fluorescent glue, white light technology, used in luminescent materials, the use of gas discharge lamps, sustainable buildings, etc., can solve problems such as immature use, achieve anti-phosphor precipitation, improve LED brightness, and high anti-yellowing coefficient. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

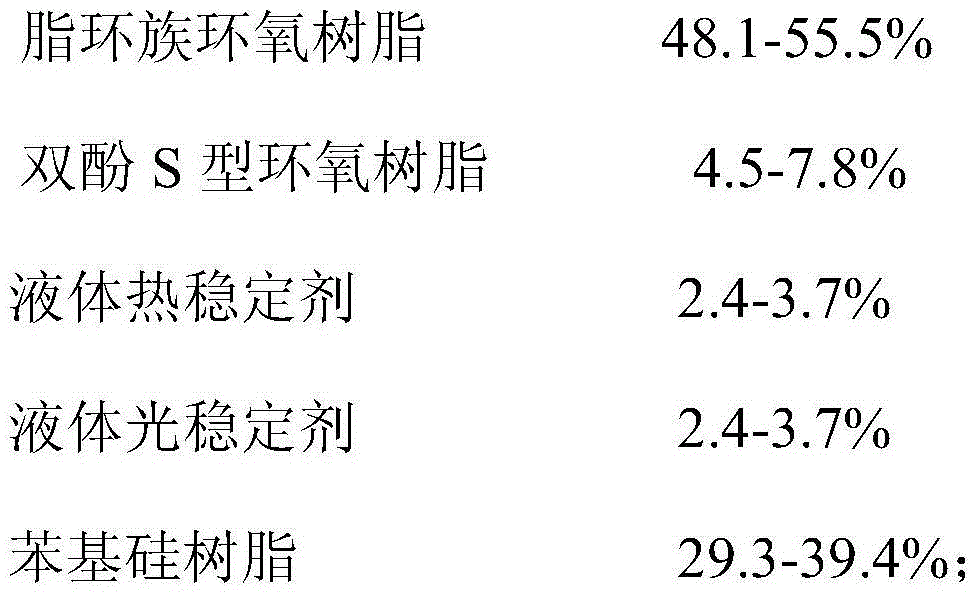

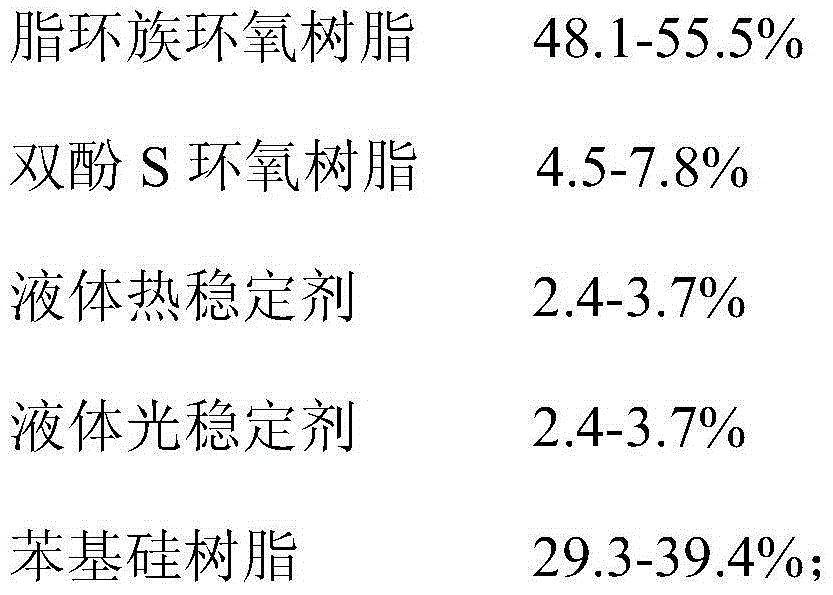

[0036]

[0037]

Embodiment 2

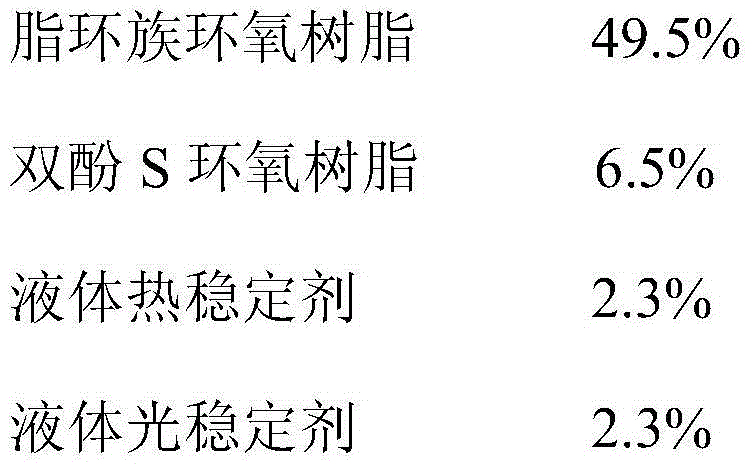

[0039]

Embodiment 3

[0041]

[0042] In embodiment 1,2,3, the concrete product model of each component is all in brackets, and each component model all adopts the name known to those skilled in the art, and all can be purchased on the market and obtain, by above-mentioned component We then perform a performance test on the formed product and obtain the following data:

[0043] Table 1 shows the product performance of embodiment 1:

[0044] Table 1

[0045]

[0046] Table 2 shows the product performance of embodiment 2:

[0047] Table 2

[0048]

[0049] Table 3 shows the product performance of embodiment 3:

[0050] table 3

[0051]

[0052]

[0053] Further, we tested Example 2 for LED lamps, and found that after aging at 30MA / 3000H, (WLD: 455-456.5NM, IV: 24-26MW, VF: 3.20-3.30V), there was no attenuation in brightness and luminous flux , There is no obvious drift in color temperature and XY, and there is no electrical failure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com