Magnetic iron oxide basis material for anti-forgery ink and preparation method thereof

A magnetic iron oxide, matrix material technology, applied in inks, applications, household appliances, etc., can solve the problems of uneven dispersion of magnetic pigments, unstable product quality, poor stability, etc., and achieve high gloss, excellent adhesion, and stable magnetic properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

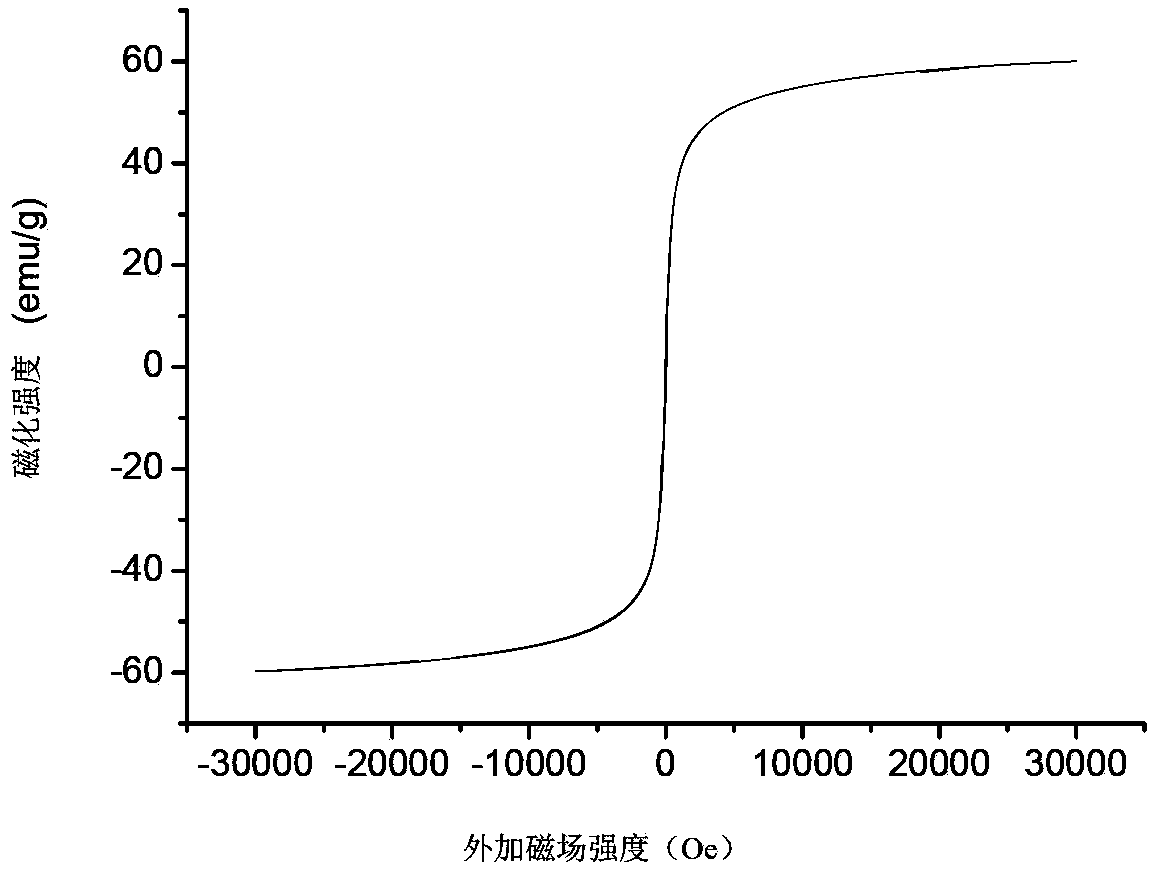

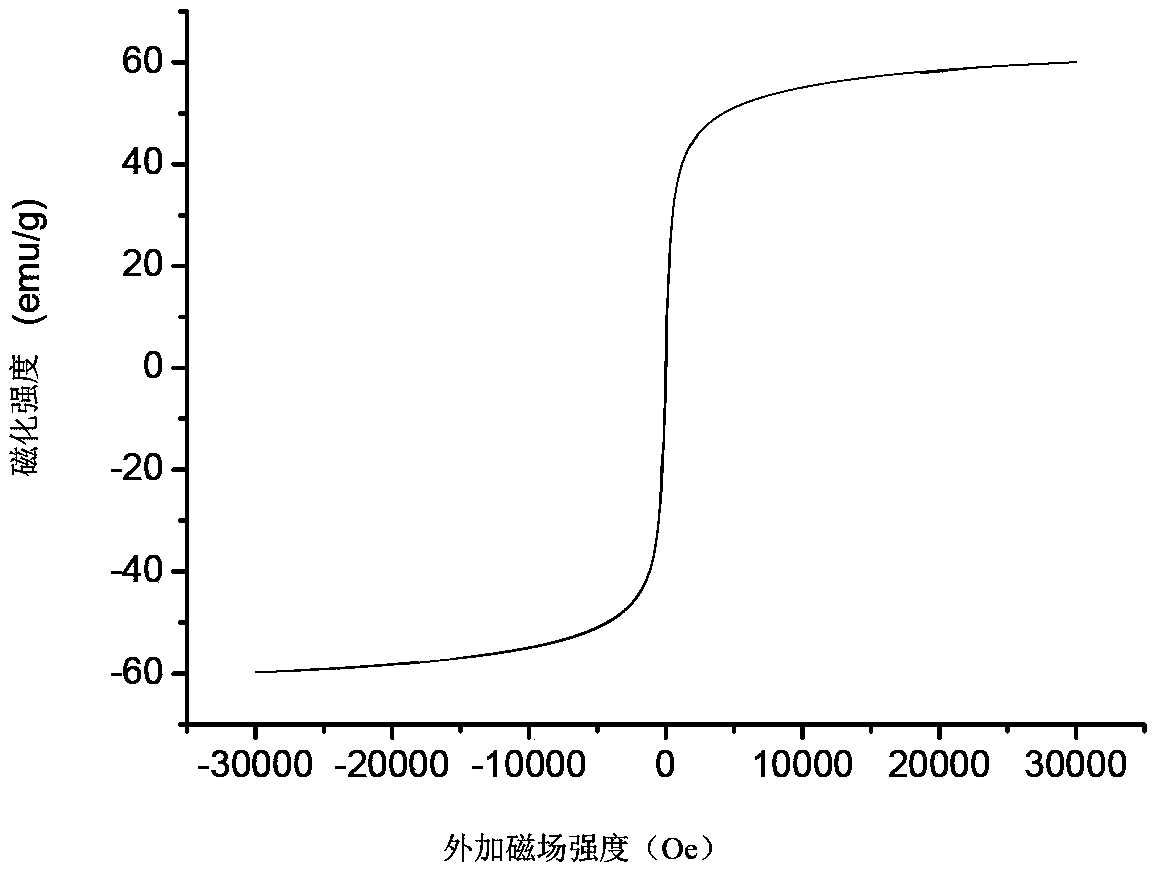

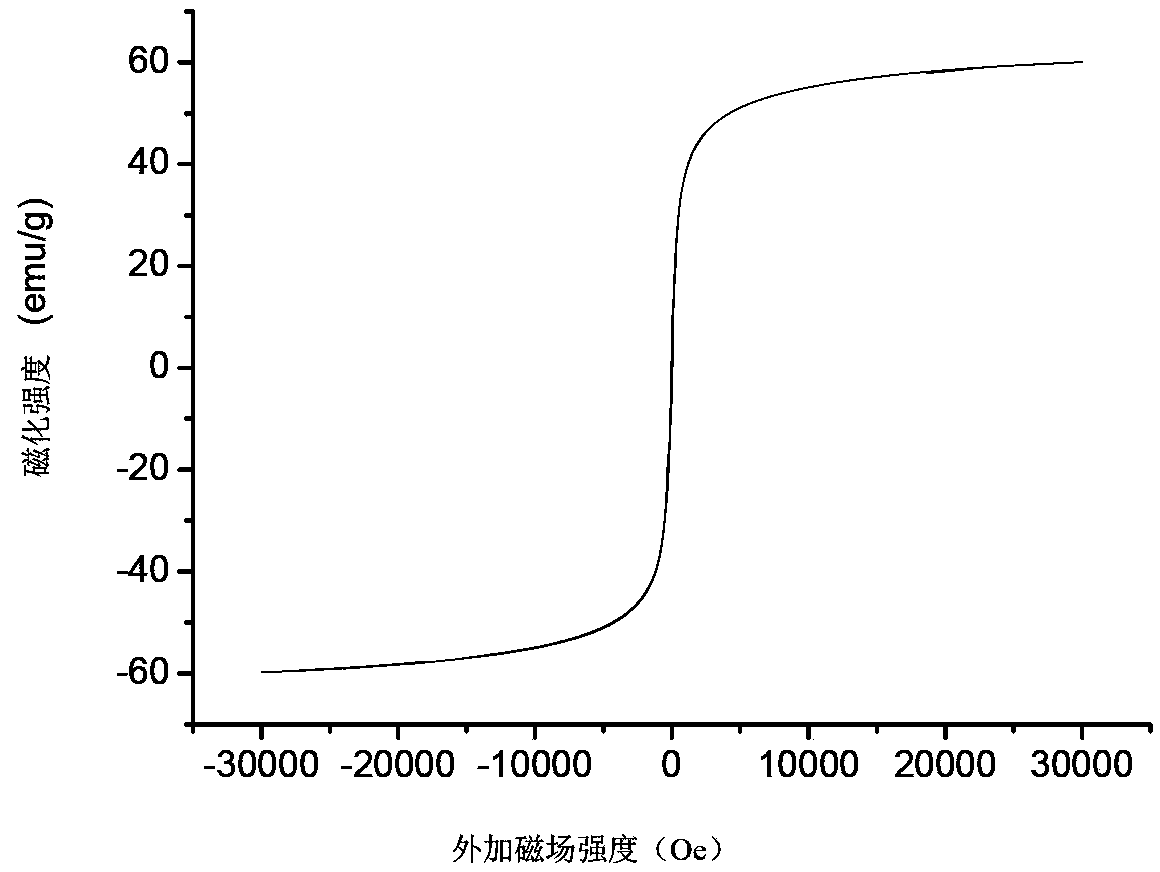

Image

Examples

preparation example Construction

[0042] 3. A method for preparing a magnetic iron oxide base material for anti-counterfeiting ink, comprising the following steps:

[0043] a. A mixture of hexamethylene diisocyanate and isophorone diisocyanate, polyethylene glycol, a mixture of dimethylol propionic acid and dimethylol butyric acid, N-methylpyrrolidone, 1,4- Butylene glycol, lithium hydroxide, ferrous chloride, ferric chloride, and deionized water are used as raw materials, and the measured polyethylene glycol, ferrous chloride, and ferric chloride are dried, and LiOH aqueous solution is configured and divided into two parts for later use;

[0044] In the step a, the drying is to dry polyethylene glycol, ferrous chloride and ferric chloride in a constant temperature drying oven at 120° C. for 2 hours.

[0045] In the step a, the concentration of the LiOH aqueous solution is 2mol / L, and the LiOH aqueous solution is divided into two parts according to the ratio of 1:4 for future use.

[0046] b. The polyethylene...

Embodiment 1

[0052] Example 1, a magnetic iron oxide matrix material for anti-counterfeiting ink, including the following raw materials in parts by weight: mixture of hexamethylene diisocyanate (HDI) and isophorone diisocyanate (IPDI): 9 parts (HDI 4 parts for IPDI, 5 parts for IPDI), polyethylene glycol-2000 (PEG-2000): 24 parts, mixture of hydrophilic chain extender dimethylol propionic acid (DMPA) and dimethylol butyric acid (DMBA) : 2 parts (DMPA and DMBA each 1 part), N-Methylpyrrolidone (NMP): 3 parts, 1,4-Butanediol (BDO): 0.5 parts, Triethylamine (TEA): 2 parts, Hydroxide Lithium (LiOH): 1.5 parts, ferrous chloride (FeCl 2 4H 2 O): 2.4 parts, ferric chloride (FeCl 3 ·6H 2 O): 4 parts, deionized water: 57 parts; catalyst butyltin dilaurate is also included, accounting for 1‰ of the total weight of the above raw materials. The raw material weight ratio table is shown in Table 1.

[0053] Table 1 Waterborne polyurethane-based magnetic Fe 3 o 4 Matching table

[0054] ...

Embodiment 2

[0065] Embodiment 2, a magnetic iron oxide base material for anti-counterfeiting ink, including the following raw materials in parts by weight:

[0066] Table 2 Waterborne polyurethane-based magnetic Fe 3 o 4 Matching table

[0067] HDI

IPDI

PEG-2000

BDO

DMBA

TEA

DMPA

LiOH

FeCl 2

FeCl 3

NMP

DBTDL

h 2 o

2

4

17

0.3

0.7

1.4

0.7

1.2

2.0

3

2.6

0.007

51

[0068] The catalyst also includes butyltin dilaurate, accounting for 0.1‰ of the total weight of the above raw materials.

[0069] Preparation method: comprising the following steps:

[0070] a , the measured PEG-2000, FeCl 2 4H 2 O and FeCl 3 ·6H 2 O was placed in a constant temperature drying oven and dried at 120 °C for 2 hours, and a 2 mol / L LiOH aqueous solution was prepared with LiOH and deionized water and divided into two parts according to the ratio of 1:4 for later use.

[0071] b , After ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com