High-curing-speed, high-storage-stability and humidity/heat-resistant de-oximed room temperature vulcanized silicone rubber for new energy and preparation method thereof

A technology of room temperature vulcanization and heat and humidity resistance, which is applied in the field of silicone rubber to achieve the effects of fast curing, reduced sensitivity and stable storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

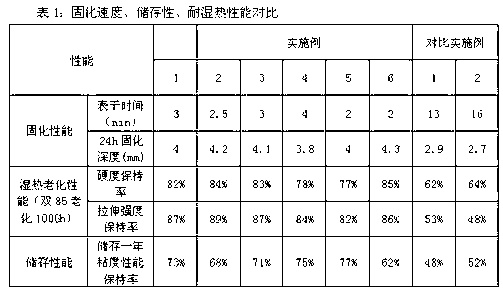

[0041] In parts by weight, 1000g molecular weight is 20,000 α, ω-dihydroxy polydimethylsiloxane, 600g nanometer calcium carbonate, 400g aluminum hydroxide, 200g molecular weight is 1000 dimethylsiloxane, in It was used as base material after vacuum stirring and dehydration for 2 hours at 120°C. Take 1000g of the base material, add 30g of vinyl tributylketoxime silane, 20g of phenyl tributylketoxime silane, 50g of white carbon black, stir well, add 1g of dibutyltin dilaurate, 10g of N-(β-ammonia Ethyl)-γ-aminopropyltrimethoxysilane, 20g C 6 h 5 NHCH 2 CH 2 CH 2 Si(OCH 3 ) 3 Tertiary aminosiloxane. The curing speed, moisture and heat resistance and storage stability of the sealant are shown in Table 1.

Embodiment 2

[0043] The base was prepared as shown in Example 1 in parts by weight. Take 1000g of the base material, add 20g of methyl tributylketoxime silane, 30g of phenyl tributylketoxime silane, 50g of white carbon black, stir evenly, add 1g of dibutyltin dilaurate, 10g of N-(β-ammonia Ethyl)-γ-aminopropyltrimethoxysilane, 20g C 6 h 5 NHCH 2 CH 2 CH 2 Si(OCH 3 ) 3 Tertiary aminosiloxane. The curing speed, moisture and heat resistance and storage stability of the sealant are shown in Table 1.

Embodiment 3

[0045] The base was prepared as shown in Example 1 in parts by weight. Take 1000g of the base material, add 25g of methyl tributylketoxime silane, 25g of phenyl tributylketoxime silane, 50g of white carbon black, stir evenly, add 1g of dibutyltin dilaurate, 10g of N-(β-ammonia Ethyl)-γ-aminopropyltrimethoxysilane, 20g C 6 h 5 NHCH 2 CH 2 CH 2 Si(OCH 3 ) 3 Tertiary aminosiloxane. The curing speed, moisture and heat resistance and storage stability of the sealant are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com