Method for purifying ruthenium complex crude product through recrystallization method

A technology for ruthenium complexes and crude products, which is applied in the field of purification of ruthenium complex crude products, can solve the problems of unfavorable industrial production, high cost, and low output, and achieve the effects of low cost, short cycle, and high output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1Z907-1

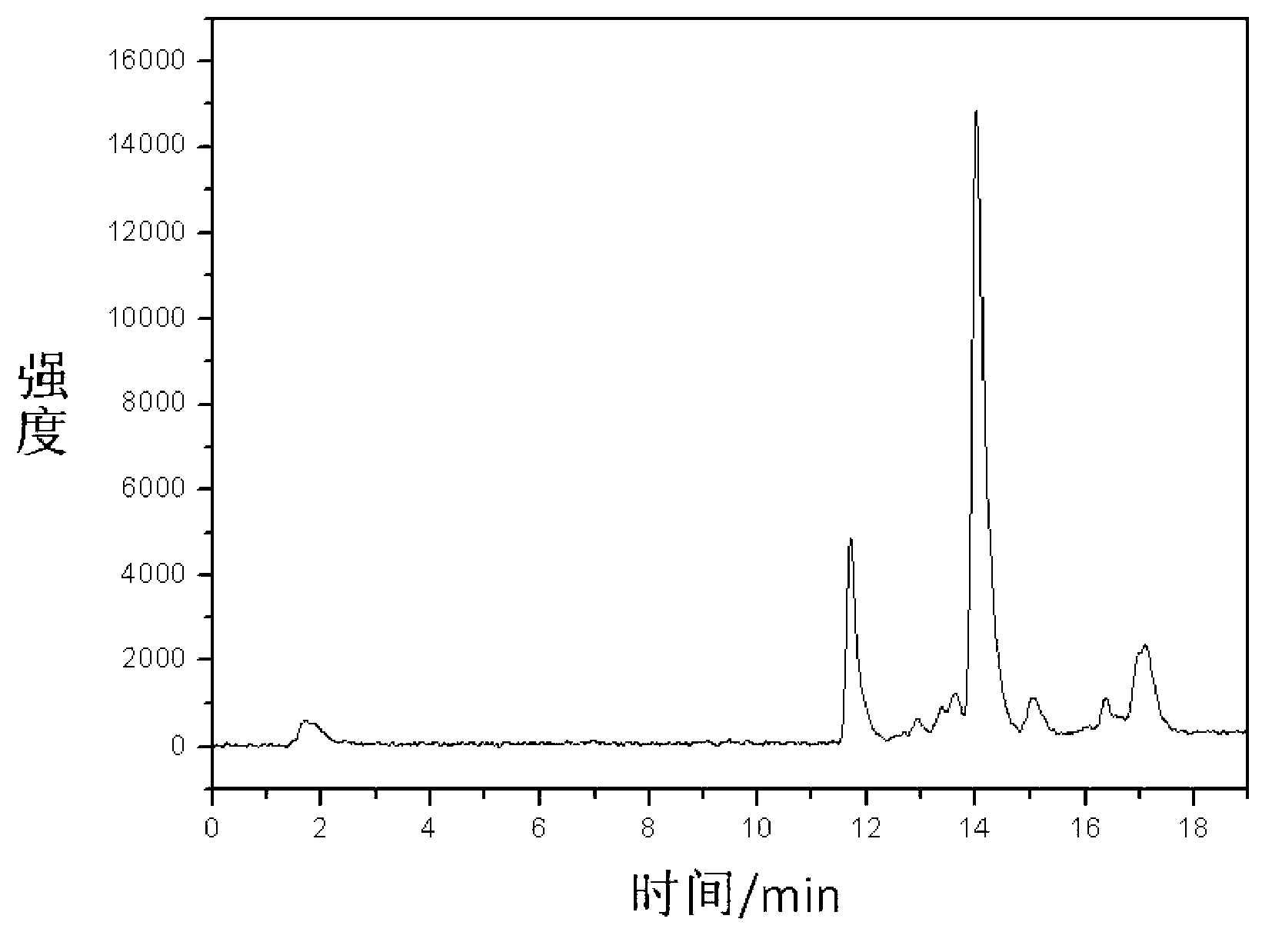

[0039] Get 5g of the Z907 crude product obtained in Comparative Example, 250mL of methanol, and 75mL of 10% tetrabutylammonium hydroxide aqueous solution into a 500mL beaker, and stir at room temperature for 1 hour with a magnetic stirrer; The solids are discarded. Add 50mL 0.1M HNO to the filtrate 3 The acid solution was acidified, and the pH value was adjusted to 5. During this process, a large amount of black solids were gradually precipitated, and the solution gradually became clear. Then filter with a filter membrane with a pore size of 10 μm to obtain a black solid, which is washed 3 times with 50 mL of water. The obtained solid was dried under vacuum at 50° C. for 10 hours to obtain 4.6 g of product Z907-1 with a yield of 92% and a purity of 62.5%. Its HPLC spectrum is as figure 2 shown.

Embodiment 2Z907-2

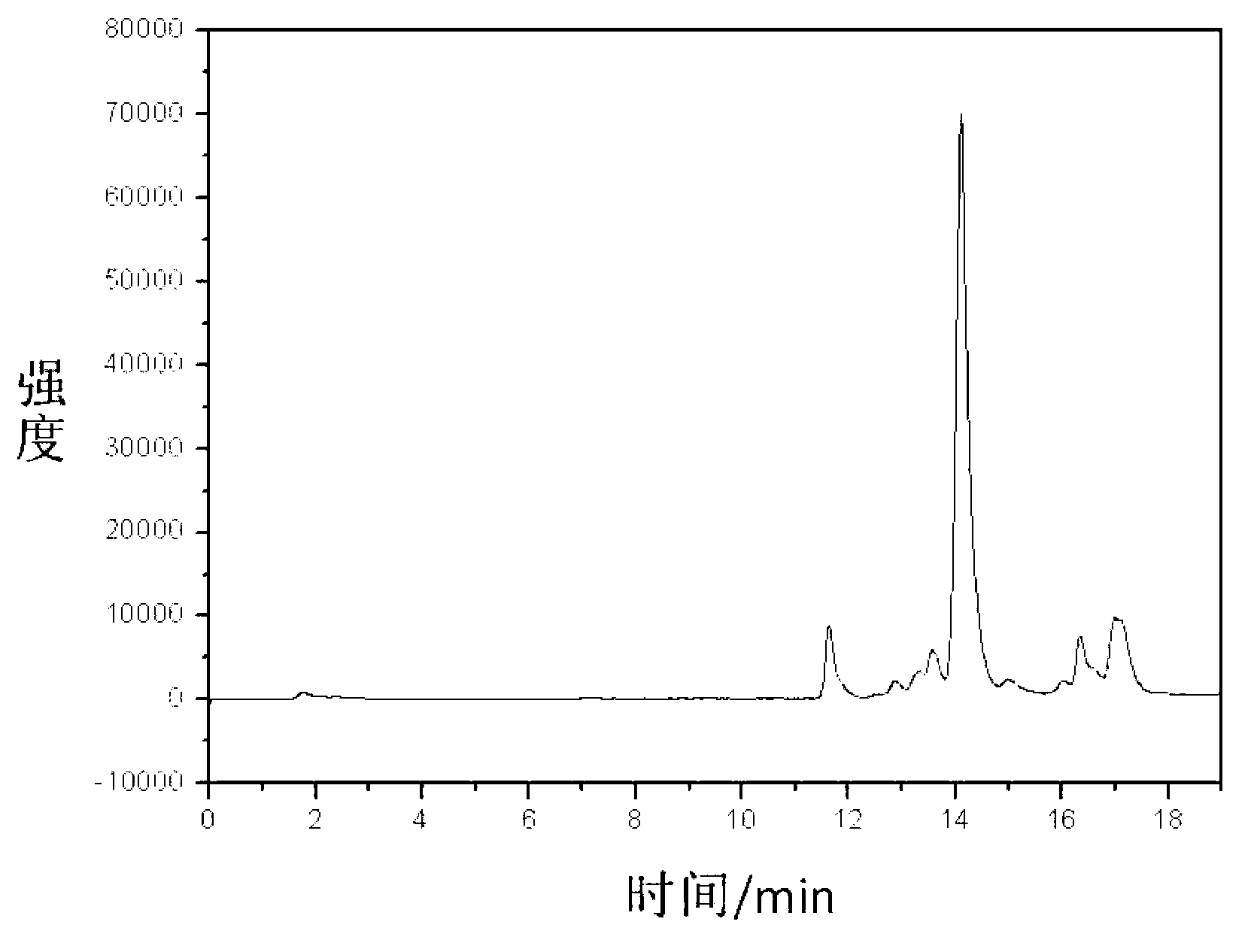

[0041] Take 5g of Z907-1 product, 250mL of methanol, and 75mL of 10% tetrabutylammonium hydroxide aqueous solution into a 500mL beaker, and stir for 1 hour at room temperature with a magnetic stirrer; the solution is filtered with a filter membrane with a pore size of 1um, and the solid on the filter membrane is discarded. Add 50mL 0.1M HNO to the filtrate 3 The acid solution was acidified, and the pH value was adjusted to 5. During this process, a large amount of black solids were gradually precipitated, and the solution gradually became clear. Then filter with a pore diameter of 10um to obtain a black solid, which was washed 3 times with 50mL of water. The obtained solid was dried under vacuum at 50° C. for 10 hours to obtain 4.8 g of product Z907-2 with a yield of 96% and a purity of 67.0%. Its HPLC spectrum is as image 3 shown.

Embodiment 3Z907-3

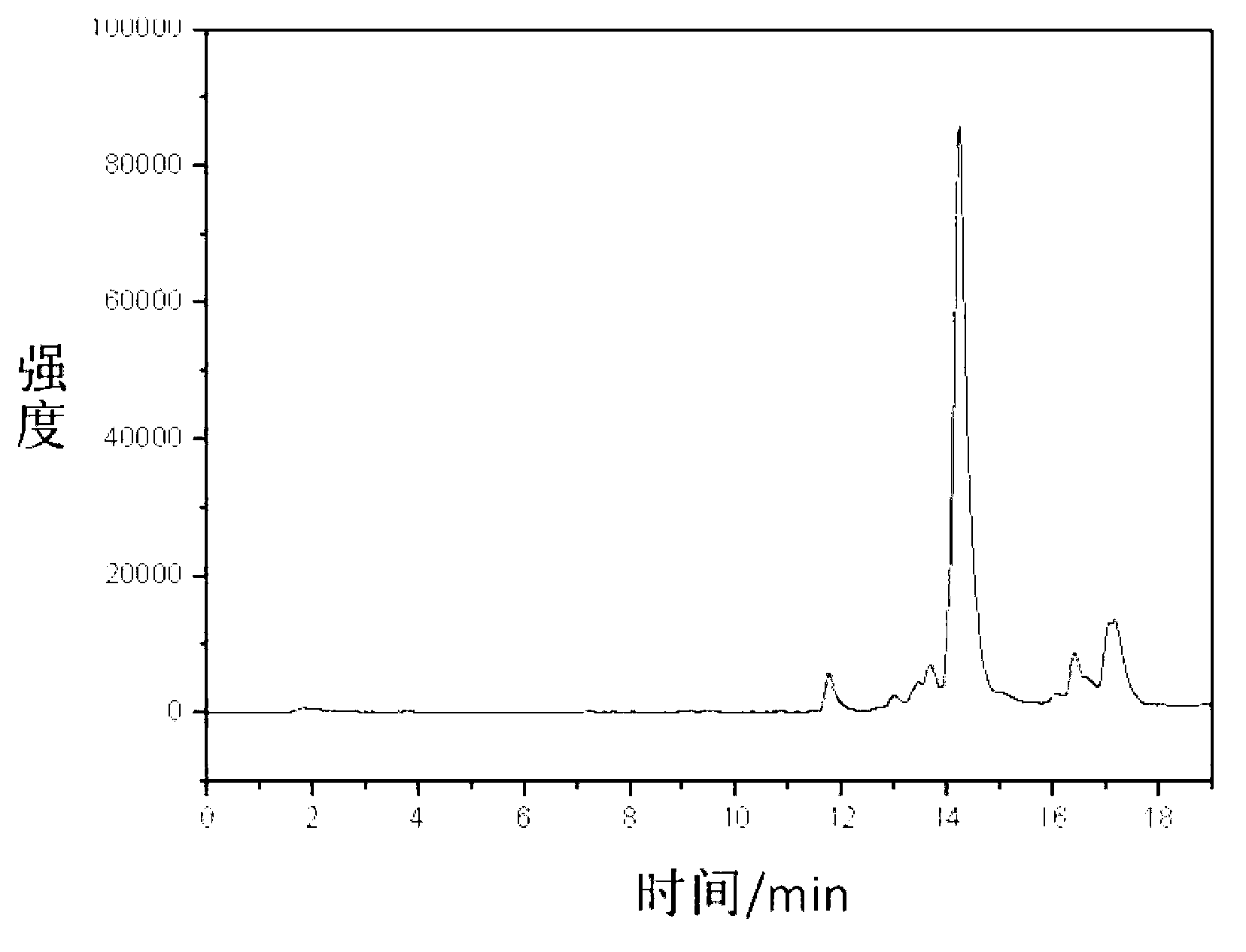

[0043] Take 5g of Z907-2, 250mL of methanol, and 75mL of 10% tetrabutylammonium hydroxide aqueous solution into a 500mL beaker, and stir for 1 hour at room temperature with a magnetic stirrer; the solution is filtered with a filter membrane with a pore size of 1um, and the solid on the filter membrane is discarded. Add 50mL 0.1M HNO to the filtrate 3 The acid solution was acidified, and the pH value was adjusted to 5. During this process, a large amount of black solids were gradually precipitated, and the solution gradually became clear. Then filter with a filter membrane with a pore size of 10 μm to obtain a black solid, which is washed 3 times with 50 mL of water. The obtained solid was dried under vacuum at 50° C. for 10 hours to obtain 4.87 g of product Z907-3 with a yield of 97.4% and a purity of 70.25%. Its HPLC spectrum is as Figure 4 shown.

[0044] Embodiment 4~7 purify ruthenium complex crude product with different amounts of lye

[0045] The Z907 crude product ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com