High voltage resisting level high molecular PTC (Positive Temperature Coefficient) thermistor and manufacturing method thereof

A thermistor and polymer technology, applied in the direction of resistance terminals/electrodes, resistors with positive temperature coefficients, etc., can solve the problems of increased process, increased cost, low efficiency, etc., to improve performance, reduce breakdown, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

[0047] Below in conjunction with example the present invention is described in further detail, but the present invention is not limited to these examples.

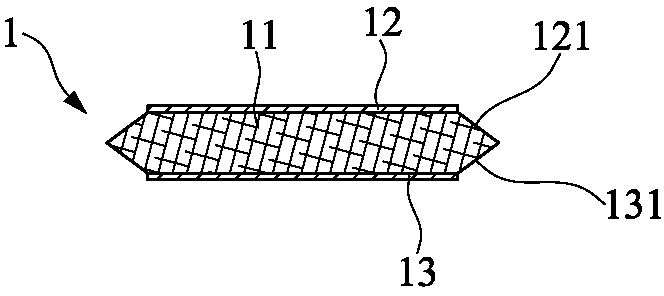

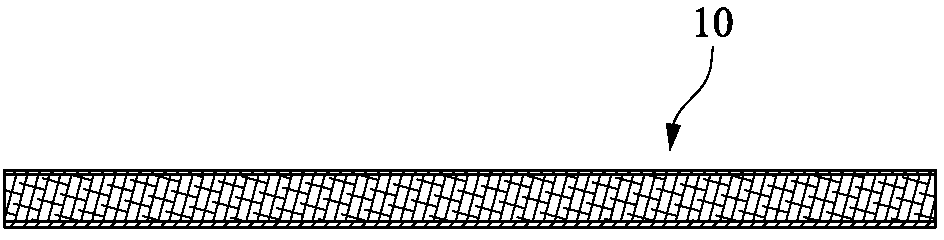

[0048] Put HDPE, carbon black, magnesium hydroxide, cross-linking agent and other additives into the internal mixer for 15 minutes, take it out and press it into a core material with a thickness of 2.3 mm at a temperature of 180 degrees with a flat vulcanizer, and sandwich it between two pieces of single-sided In the roughened nickel-plated copper foil electrode, use a flat vulcanizer under the conditions of 180 degrees and 50MPa pressure to compound the copper foil electrode on both sides of the core material, and press it into a 2 mm thick PPTC sheet.

[0049] The cutting knife is transformed with a 2 mm thick disc milling cutter, and the circumferential knife edge is ground into two oblique angles of 45 degrees with the center line of the plane with a tool grinder.

[0050] Install the cutting knife on the milling machi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com