Solar cells and diffusion method thereof

A technology of solar cells and diffusion methods, applied in the field of solar cells, can solve the problems of low conversion efficiency of solar cells, achieve the effects of increasing concentration gradient distribution and carrier life, increasing absorption rate, and improving spectral responsivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

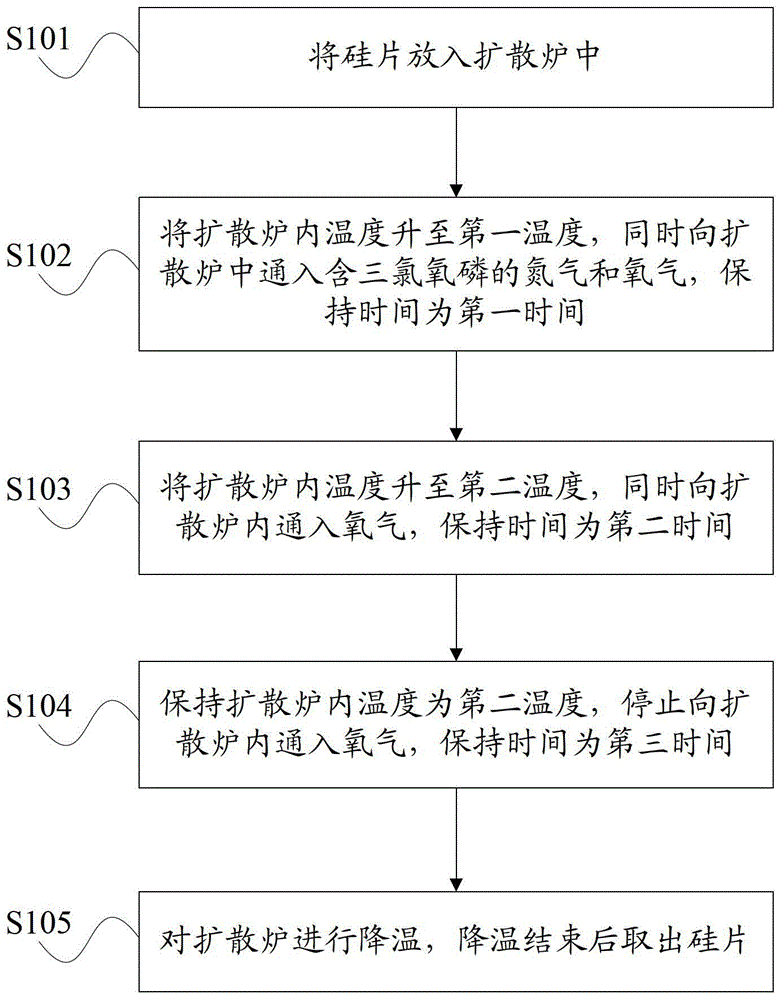

[0044] The flow chart of the diffusion method disclosed in this embodiment is as follows: figure 1 shown, including steps:

[0045] S101: Put the silicon wafer into the diffusion furnace.

[0046] Wherein, the silicon wafer is the silicon wafer to be diffused during the solar cell production process.

[0047] S102: Raise the temperature in the diffusion furnace to the first temperature, and at the same time, feed nitrogen and oxygen containing phosphorus oxychloride into the diffusion furnace for the first time.

[0048]Wherein, the range of the first temperature is 780°C~800°C, including the endpoint value, the range of the first time is 11.5min~13.5min, including the endpoint value, and the nitrogen and oxygen gas containing phosphorus oxychloride Flow ratios range from 2:1 to 3:1, including endpoints. The function of this step is to deposit impurities on the surface of the silicon wafer to form a certain concentration, which facilitates the further diffusion of impuritie...

Embodiment 2

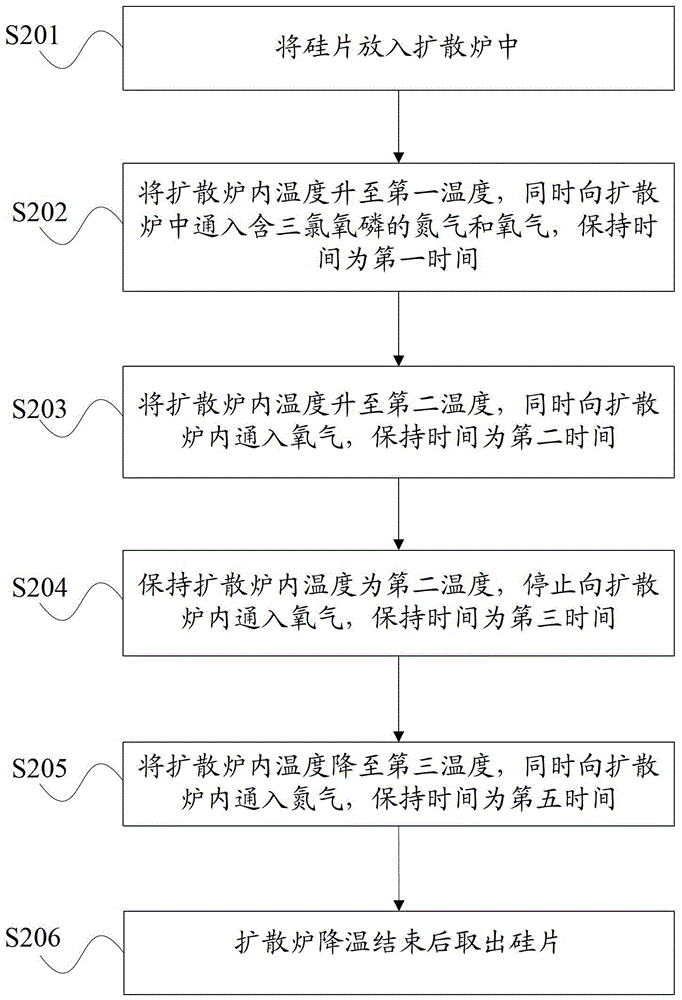

[0056] The flow chart of the diffusion method disclosed in this embodiment is as follows: figure 2 As shown, the specific steps are as follows:

[0057] Steps S201-S204 are the same as steps S101-S104, and will not be repeated here.

[0058] S205: Decrease the temperature in the diffusion furnace to the third temperature, and at the same time, feed nitrogen gas into the diffusion furnace for a fifth time.

[0059] Wherein, the range of the third temperature is 730°C~750°C, inclusive, the range of the fifth time is 10min~15min, inclusive, and the flow rate of nitrogen is 1000sccm~2000sccm, inclusive. If the silicon wafer is directly cooled out of the furnace after the diffusion is completed, the temperature difference will be too large. At this time, the residual thermal stress in the silicon wafer will bend or crack the silicon wafer. Therefore, in the diffusion method provided in this embodiment, after the temperature of the diffusion furnace drops to 730°C~750°C, nitrogen...

Embodiment 3

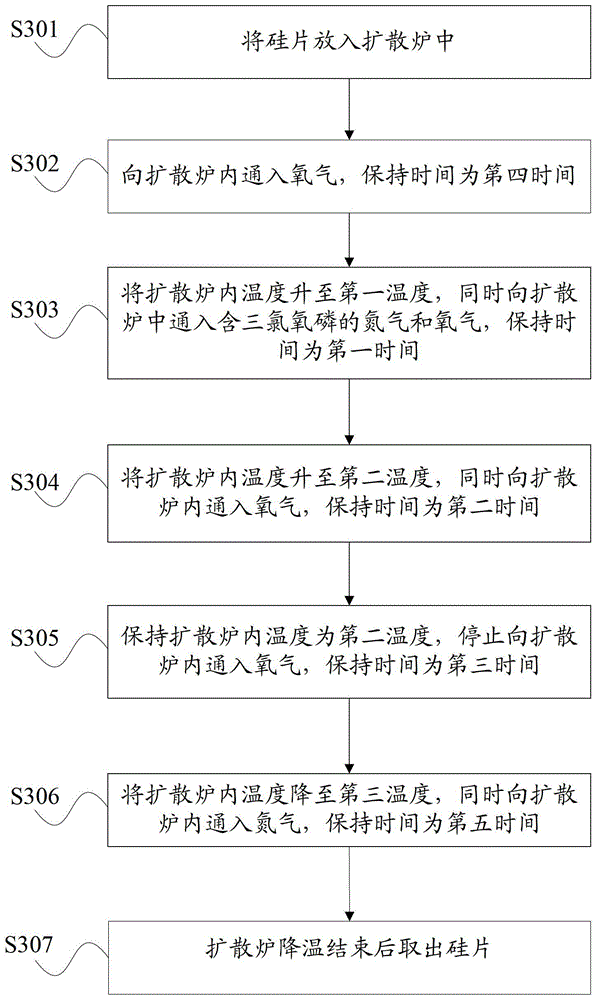

[0063] The flow chart of the diffusion method disclosed in this embodiment is as follows: image 3 As shown, the specific steps are as follows:

[0064] S301: Putting the silicon wafer into a diffusion furnace.

[0065] Wherein, the silicon wafer is a silicon wafer to be diffused in the solar cell production process.

[0066] S302: Pass oxygen into the diffusion furnace, and keep it for a fourth time.

[0067] Wherein, the fourth time ranges from 1 min to 3 min, including endpoint values. Although the step of oxidizing the silicon wafer before diffusion is eliminated, the problem that the silicon dioxide layer on the surface of the silicon wafer is too thick and affects the diffusion of impurities can be avoided, but oxygen is introduced into the diffusion furnace before the diffusion of the silicon wafer, and the formed A silicon dioxide layer with a certain thickness is used as a masking film during diffusion to reduce the damage caused by the high concentration of impuri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com