Method for Improving Electrochemical Performance of High Nickel Ternary Cathode Material

A positive electrode material and electrochemical technology, applied in the direction of circuits, electrical components, battery electrodes, etc., can solve the problems of high nickel ternary positive electrode materials such as poor rate and cycle performance, and achieve good rate and cycle performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

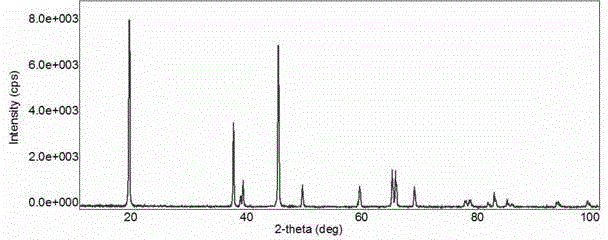

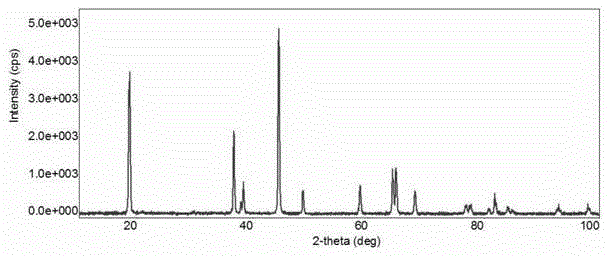

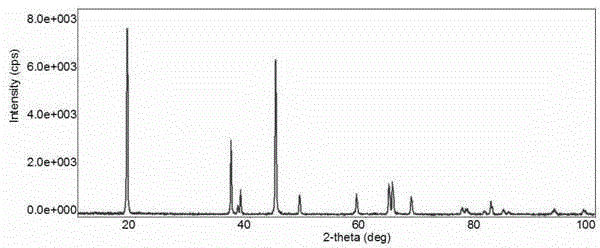

[0040] Put 12.78 grams of lithium hydroxide (purity 99.5%) into 1 liter of water for dissolution, then put 1 kilogram of LiNi synthesized in Comparative Example 1 and crushed and classified under stirring conditions. 0.5 co 0.2 mn 0.3 o 2 Material; Dissolve 88.58 grams of cobalt nitrate (purity 99.5%) in 1 liter of water in another container; Slowly add the dissolved cobalt nitrate solution to the continuously stirred LiNi 0.5 co 0.2 mn 0.3 o 2 In the LiOH solution of the material, the whole dropwise addition process takes 30 minutes. After the cobalt nitrate solution was added dropwise, the stirring was continued for 30 minutes, and then the mixed solution was spray-dried to obtain a powder mixture. Finally, the material obtained after sintering the powder mixture in a box furnace at 750°C for 5 hours is coated LiNi 0.5 co 0.2 mn 0.3 o 2 Material. figure 2 and image 3 They are the XRD spectra of the unsintered and sintered materials after coating, respectively. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com