Gel polymer electrolyte based on non-woven fabrics for lithium ion battery and preparation method of gel polymer electrolyte

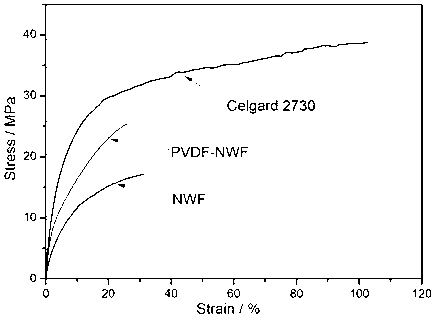

A gel polymer, lithium-ion battery technology, applied in the field of lithium-ion batteries, can solve the problems of extremely difficult to widely use, high production cost, poor mechanical strength, etc., and achieves low production cost, high mechanical strength, and high electrical conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

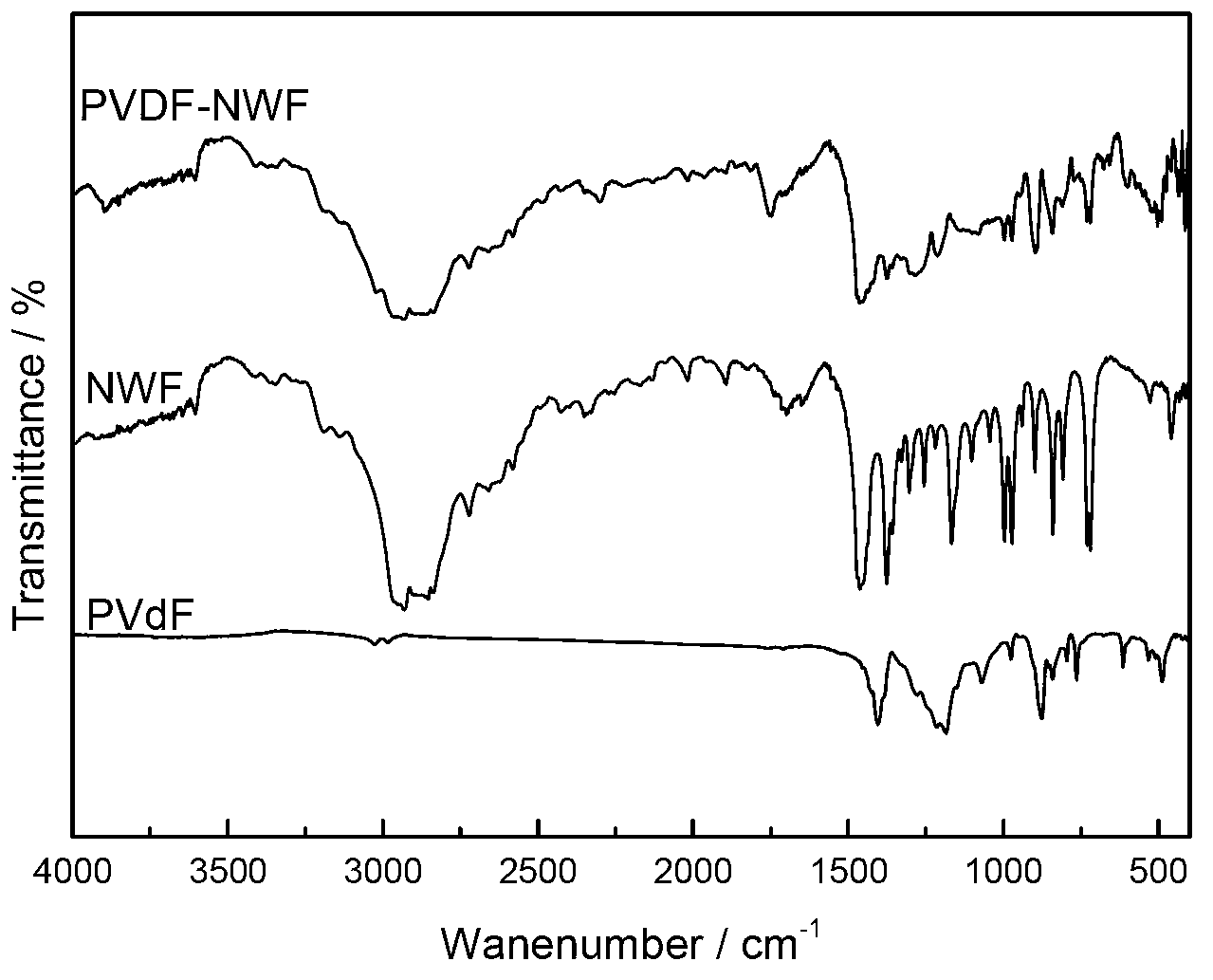

[0031] (1) Dissolve PVDF in DMAc at a mass percentage of 10%, at 40 oHeated and stirred in a water bath of C for 2 hours to obtain a clear and homogeneous solution, and cooled to room temperature.

[0032] (2) Fix the non-woven fabric (material: PP / PE) on a smooth and clean glass plate, pour the prepared PVDF solution on the non-woven fabric, scrape it with a scraper, and place it at 80 o C The solvent was evaporated on the heating plate, and after 4 hours, it was removed and cooled to room temperature. Put the surface of the non-woven fabric poured with PVDF close to the glass plate to fix the non-woven fabric, pour the coating solution on the non-woven fabric, scrape it with a scraper, and place it at 80 o C The solvent was evaporated on the heating plate, and after 4 hours, it was removed and cooled to room temperature to obtain a PVDF composite non-woven fabric (PP / PE).

[0033] (3) After cutting the PVDF composite non-woven fabric into an appropriate size, place it in a...

Embodiment 2

[0035] (1) Dissolve PVDF-HFP in DMAc at a mass percentage of 10%, at 60 o C in a water bath with heating and stirring for 2 hours to obtain a clear and homogeneous solution. Cool to room temperature and set aside.

[0036] (2) Fix the non-woven fabric (PP / PE) on a smooth and clean glass plate, pour the prepared PVDF-HFP solution on the non-woven fabric, scrape it with a scraper, and place it at 80 o C The solvent was evaporated on the heating plate, and after 4 hours, it was removed and cooled to room temperature. Put the surface of the non-woven fabric that has poured PVDF-HFP close to the glass plate to fix the non-woven fabric, pour the coating solution on the non-woven fabric, scrape it with a scraper, and place it at 80 o C The solvent was evaporated on the heating plate, and after 4 hours, it was removed and cooled to room temperature to obtain a PVDF-HFP composite non-woven fabric (PP / PE).

[0037] (3) After cutting the PVDF-HFP composite non-woven fabric into an app...

Embodiment 3

[0039] (1) Dissolve PVDF in DMAc at a mass percentage of 10%, at 80 o C in a water bath with heating and stirring for 1.5 hours to obtain a clear and homogeneous solution. Cool to room temperature and set aside.

[0040] (2) Fix the non-woven fabric (soybean fiber) on a smooth and clean glass plate, pour the prepared PVDF solution on the non-woven fabric, scrape it with a scraper, and place it at 80 o C The solvent was evaporated on the heating plate, and after 4 hours, it was removed and cooled to room temperature. Put the surface of the non-woven fabric poured with PVDF close to the glass plate to fix the non-woven fabric, pour the coating solution on the non-woven fabric, scrape it with a scraper, and place it at 80 o C. Volatile solvent on the heating plate, take it off after 4 hours and cool to room temperature to obtain PVDF composite non-woven fabric (soybean fiber).

[0041] (3) After cutting the PVDF composite non-woven fabric into an appropriate size, place it in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com