Method for treating titanium-containing waste liquid produced by polyolefin catalyst

A polyolefin catalyst and treatment method technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, neutralized water/sewage treatment, etc. The effect of transportation and processing cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

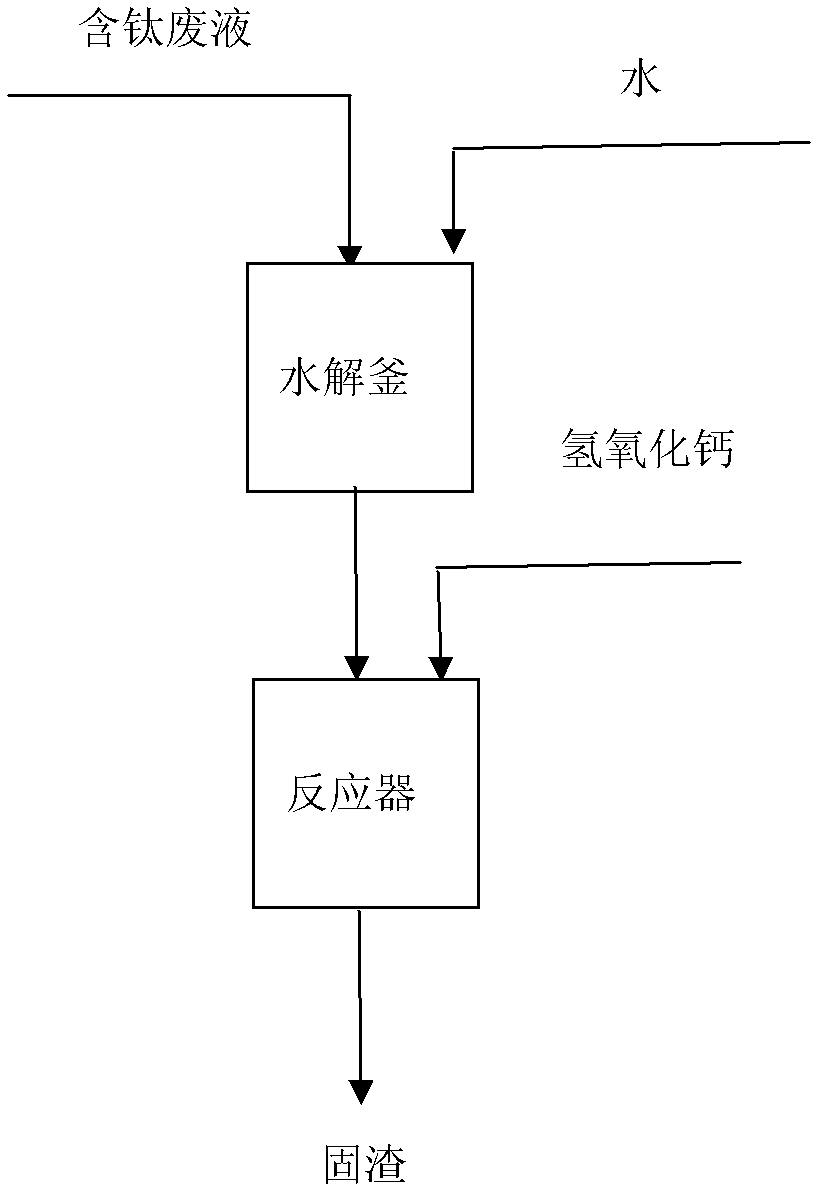

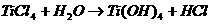

[0023] Add 124g of water into the hydrolysis kettle, and then slowly add 62g of titanium-containing waste liquid after preliminary distillation and recovery of part of titanium tetrachloride into the hydrolysis kettle. The hydrolysis kettle adopts a water jacket to cool down, and controls the addition rate of titanium-containing waste liquid so that the reaction temperature during hydrolysis does not exceed 70°C. 62g lime (Ca(OH) 2 ) powder is directly and slowly added to the kneader, and then the acidic hydrolyzate obtained in the first step is transferred to the kneader through the pipeline for neutralization. The kneader uses a water jacket to cool down, so that the reaction temperature does not exceed 70°C during neutralization. After the neutralization reaction is completed, 248g of solid residue is finally formed, which can be further disposed of.

Embodiment 2

[0025] Add 100 g of water into the hydrolysis tank, and then slowly add 200 g of titanium-containing waste liquid after preliminary distillation and recovery of part of titanium tetrachloride into the hydrolysis tank. The hydrolysis kettle adopts a water jacket to cool down, and controls the addition rate of titanium-containing waste liquid so that the reaction temperature during hydrolysis does not exceed 80°C. 100 g lime (Ca(OH) 2 ) powder is directly and slowly added to the screw mixer, and then the acidic hydrolyzate obtained in the first step is transferred to the screw mixer through the pipeline for neutralization. The spiral mixer uses a water jacket to cool down, so that the reaction temperature does not exceed 70°C during neutralization. After the neutralization reaction is completed, 400g of solid residue is finally formed, which can be further disposed of.

Embodiment 3

[0027] Add 120g of water into the hydrolysis kettle, and then slowly add 40g of titanium-containing waste liquid after preliminary distillation and recovery of part of titanium tetrachloride into the hydrolysis kettle. The hydrolysis kettle adopts a water jacket to cool down, and controls the addition rate of titanium-containing waste liquid so that the reaction temperature during hydrolysis does not exceed 70°C. 40g lime (Ca(OH) 2 ) powder is directly and slowly added to the kneader, and then the acidic hydrolyzate obtained in the first step is transferred to the kneader through the pipeline for neutralization. The kneader uses a water jacket to cool down, so that the reaction temperature does not exceed 80°C during neutralization. After the neutralization reaction is completed, 200g of solid residue is finally formed, which can be further disposed of.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap