Colored rock paint and preparation method thereof

A technology of colored stone paint and colored sand, applied in the field of colored stone paint, can solve the problems such as the richness and diversity of colored stone paint, the generation of color difference, and the lack of three-dimensional effect, and the effect of easy color reconciliation, convenient packaging and strong three-dimensional effect can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

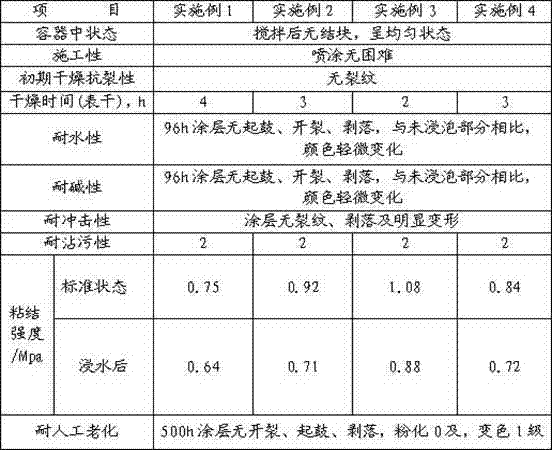

Examples

Embodiment 1

[0017] Embodiment 1: The colored stone paint disclosed by the present invention comprises colored sand and acrylic latex powder, and the mass percentages of each component in the colored stone paint are 90% of colored sand and 9% of acrylic latex powder.

[0018] The above-mentioned colored stone paint formula also includes a thickener, and the mass percentage of the thickener in the colored stone paint is 0.05-0.1%. The selected thickener has a viscosity of 20000-150000mpa at a temperature of 20-30°C ﹒ s hydroxypropyl methylcellulose ether.

[0019] The fineness of the colored sand in the above-mentioned colored stone paint formula is 10-140 mesh.

[0020] The method for producing colored stone paint according to the present invention, the production method is to mix 10-140 mesh colored sand, acrylic latex powder and thickener according to the mass percentage of each component in colored stone paint: colored sand 90%, acrylic latex powder 9% Thickener 0.05-0.1% is put into ...

Embodiment 2

[0022] Embodiment 2: The formula of the colored stone paint of the present invention is 93% of colored sand, 6% of acrylic latex powder, 0.05% of thickener, and 1% of inorganic pigment. The above-mentioned percentages are the mass percentages of each component in the colored stone paint.

[0023] The fineness of the colored sand in the above-mentioned colored stone paint formula is 10-140 mesh, the thickener is selected at a temperature of 20-30°C, and the viscosity is 20000-150000mpa. s hydroxypropyl methylcellulose ether.

[0024] The inorganic pigments added in the colored stone paint include one, two or more mixtures of iron oxide red, iron oxide yellow, phthalocyanine blue, and cobalt blue.

[0025] The method for producing the colored stone paint of this embodiment, the production method is to put 10-140 mesh colored sand, acrylic latex powder, thickener, and inorganic pigment into the twin-screw dry powder mortar mixer according to the above mass percentage and stir at ...

Embodiment 3

[0026] Embodiment 3: The formula of the colored stone paint of the present invention is 92% of colored sand, 7% of acrylic latex powder, 0.08% of thickener, and 0.06% of inorganic pigment. The above-mentioned percentages are the mass percentages of each component in the colored stone paint.

[0027] The fineness of the colored sand in the above-mentioned colored stone paint formula is 10-140 mesh, the thickener is selected at a temperature of 20-30°C, and the viscosity is 20000-150000mpa. s hydroxypropyl methylcellulose ether.

[0028] The inorganic pigments added in the colored stone paint include one, two or more mixtures of iron oxide red, iron oxide yellow, phthalocyanine blue, and cobalt blue.

[0029] Production method is the same as embodiment two.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com