Low-temperature oxidation coloring treatment process method for workpiece on surface of clutch driven plate

A processing technology and clutch technology, applied in metal material coating technology, coating, solid diffusion coating and other directions, can solve the problem of chemical residual liquid pollution and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

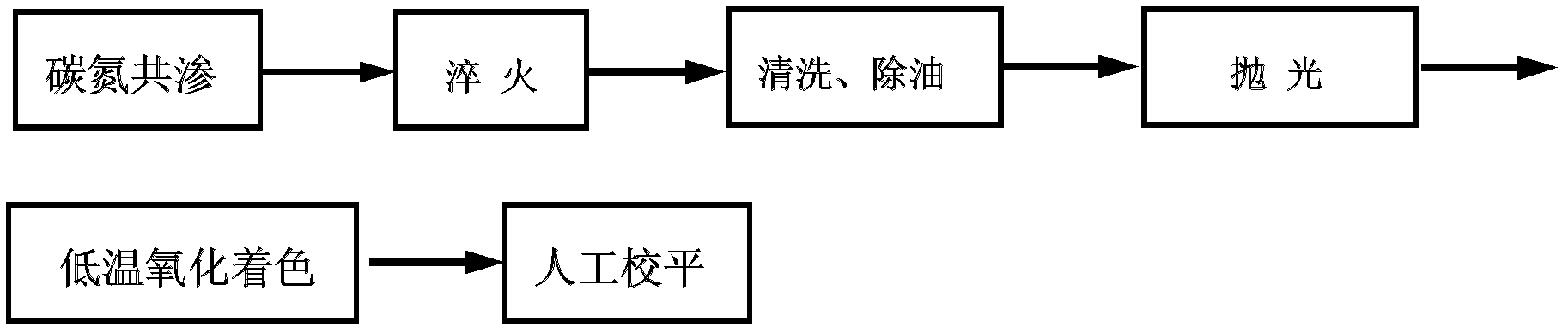

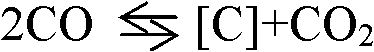

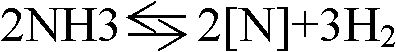

[0045] 1. C-N co-infiltration and quenching.

[0046] 2. Cleaning; the workpiece is cleaned by a washing machine.

[0047] 3. Degreasing; add an appropriate amount of alkaline cleaning agent (model: HJ-921A, main purpose: removal of oil stains on metal surfaces), heating temperature 70°C-80°C, degreasing time 5-10 minutes (determined according to the amount of oil stains on the workpiece surface) ), the range of PH value 8-10.

[0048] 4. Polishing:

[0049] (1) The workpiece needs to be polished to remove surface black spots and oxide scales to make the surface bright;

[0050] (2) Quality control: After the surface is polished, it should be uniform and bright, and no oil stains are allowed.

[0051] After the surface is polished, the coloring process is specifically as follows: in a relatively low temperature environment of the mesh belt furnace (the relative carbonitriding temperature is controlled above 700 ° C), by controlling different time and temperature, oxidation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com