Coaxial strain sensor filled with discontinuous media

A strain sensor and sensor technology, applied in the direction of electric/magnetic solid deformation measurement, electromagnetic measurement device, etc., can solve the problems of difficult anti-corrosion treatment, reduced mechanical strength, difficult to bend, etc., and achieve easy processing, production and application, and good deformation ability , the effect of not being easily corroded

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

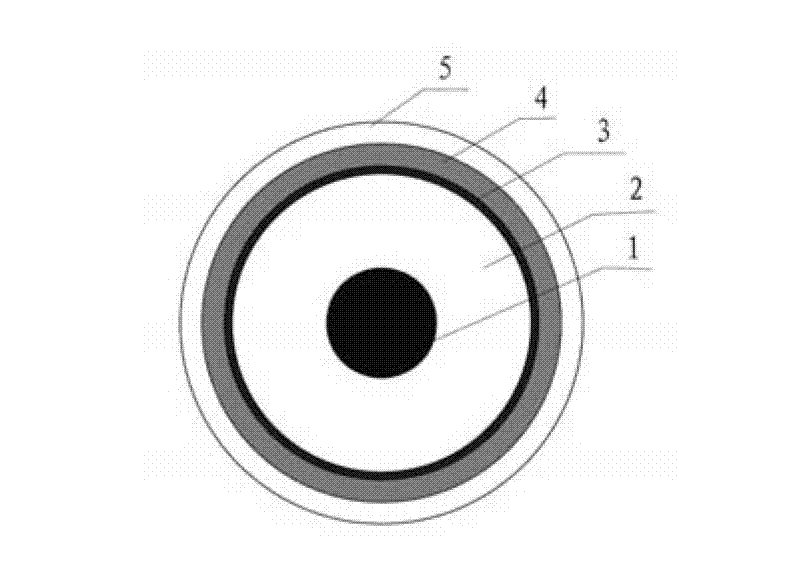

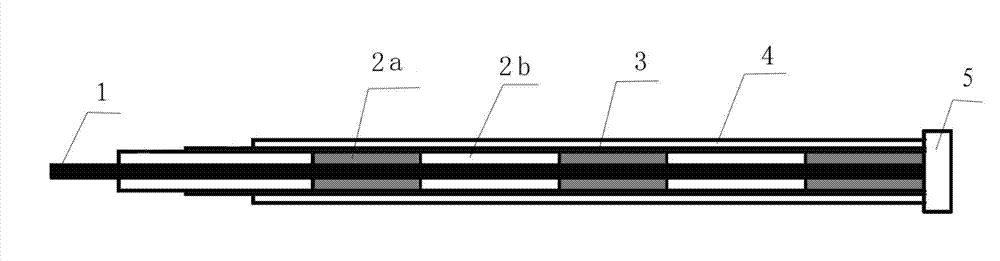

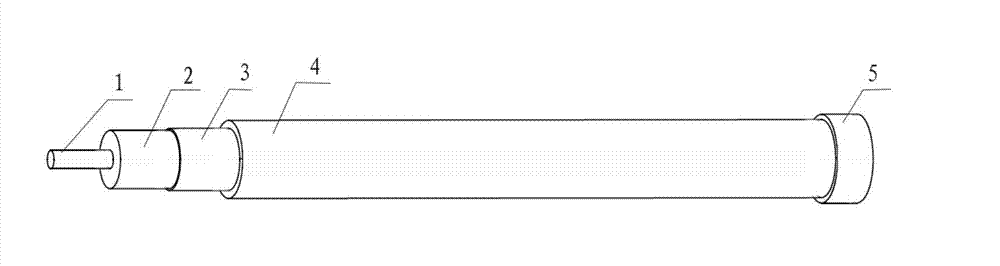

[0044] The insulating section I2a and the insulating section II2b are made of FR4 and Teflon respectively, and the dielectric constants are 4.4 and 2.1 respectively. The predetermined initial monitoring frequency point is 5GHz, and the calculated length of insulation section I2a is 7.151mm, and the length of insulation section II2b is 10.352mm. The inner diameter of the insulating layer is 0.73mm, and the outer diameter is 2.3mm.

[0045] The structure formed by connecting an insulating segment I2a and an insulating segment II2b in series is called a cycle, and a total of 5 cycles are introduced. initial curve as Figure 5 As shown by the middle black solid line (before straining), the reflection coefficient extreme frequency point appears at 5GHz. Stretch the sensor, the strain is changed from 0 to 0.2 with a step size of 0.02, then the final monitoring frequency point is shifted from 5GHz to 4.167GHz, Figure 5 Curve after medium strain. Image 6 It is the relationship d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com