System and method for testing catalyst dehydrogenation performance

A technology for testing systems and catalysts, which is applied in the direction of chemical analysis using catalysis, can solve the problems of high container requirements, high energy consumption, and can not meet the performance test of hydrogen elimination catalysts, and achieves the effect of ensuring accuracy and low energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

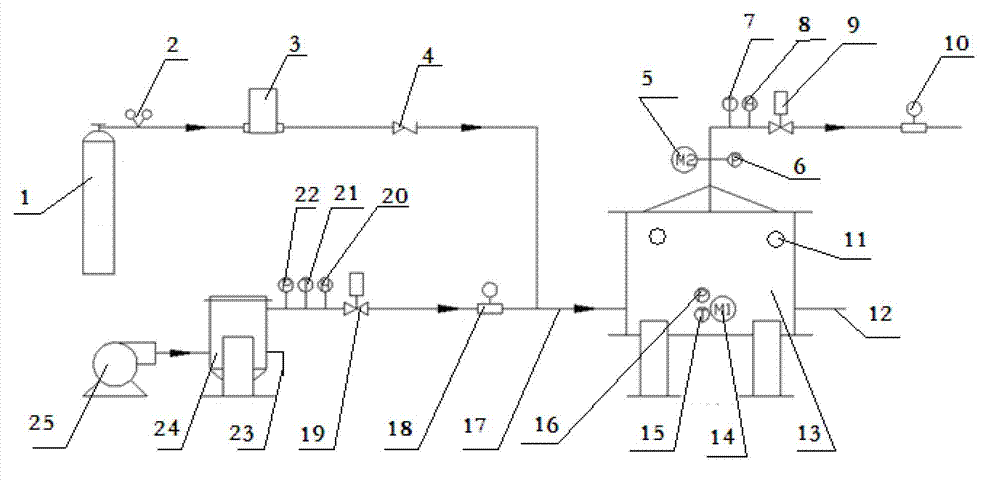

[0063] A test system for catalyst dehydrogenation performance, said system comprising: a hydrogen cylinder 1, a pressure reducing valve 2, a mass flow meter 3, a check valve 4, an air compressor 25, a buffer tank 24, a first electric regulating valve 19, First swirl flowmeter 18, mixing gas distribution pipe 17, catalytic reactor 13, second electric control valve 9, second swirl flowmeter 10, first pressure transmitter 22, first thermocouple 21, first humidity Meter 20, second pressure transmitter 6, second thermocouple 7, second hygrometer 8 and data acquisition control system;

[0064] Among them, the hydrogen cylinder 1, the pressure reducing valve 2, and the mass flow meter 3 are sequentially connected through pipelines, and then connected to one end of the check valve 4;

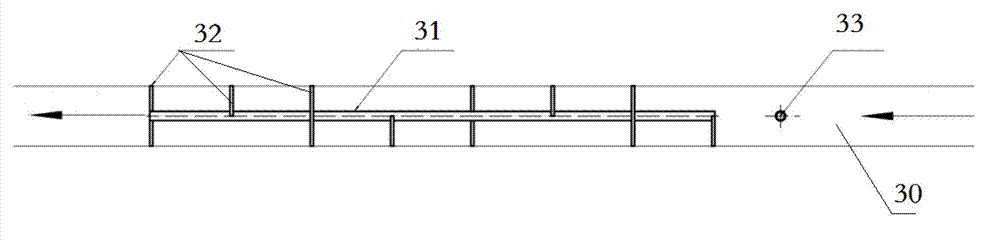

[0065] The buffer tank 24 bottom has an air inlet, and the upper part has an air outlet; after the air compressor 25, the buffer tank 24 inlet, the buffer tank 24 air outlet, and the first electric regu...

Embodiment 2

[0088] A kind of test system of catalyst dehydrogenation performance, the difference between described system and embodiment 1 is:

[0089] The lower part of the side wall of the buffer tank 24 has a first liquid filling port 23, and a second liquid filling port 12 is opened below the side wall of the catalytic reactor 13;

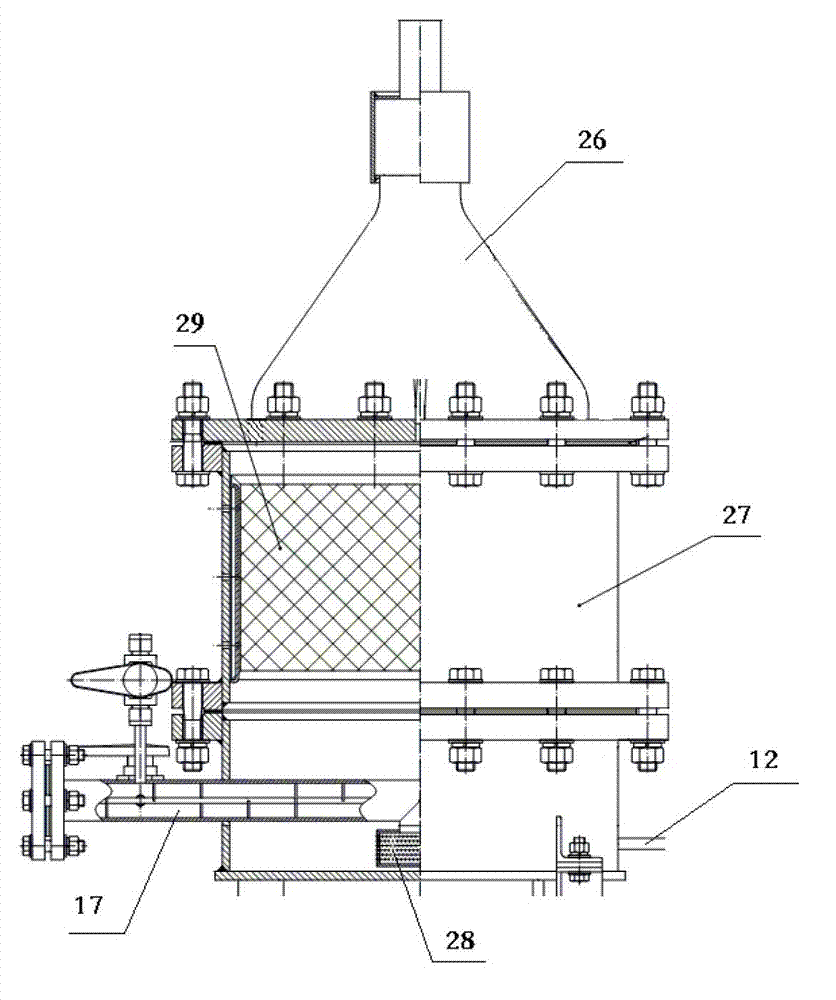

[0090] In the catalytic reactor 13, the catalyst plate 29 in the box body 27 is a rectangular box with a grid structure on the surface and a thickness of 6-12 mm, and contains catalyst pellets;

[0091] A method for testing the dehydrogenation performance of a catalyst, the specific steps of the method are as follows:

[0092] Before the test starts, the non-return valve is in the open state, and all other valves are in the closed state;

[0093] Step 1. Open the first electric regulating valve 19, turn on the air compressor 25, fill the buffer tank 24 with compressed air with a pressure of 0.1~0.7MPa, and the air passes through the first electric regulat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com