Preparation method for glass micro-bead sedimentation type light-reflective membrane

A technology of glass beads and reflective film, which is applied in the field of reflective film, can solve the problems of low production efficiency, high production cost, and low yield, and achieve the effects of increased production efficiency, improved product yield, and good molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

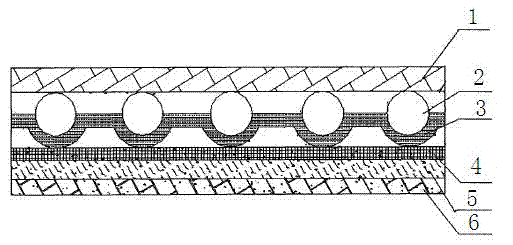

[0025] like figure 1 As shown, the reflective film of the present invention is composed of a reflective film layer 1 , a glass bead layer 2 , a focusing resin layer 3 , a metal reflective layer 4 , a pressure-sensitive adhesive layer 5 and an anti-sticking paper layer 6 .

[0026] The specific production process of the present invention is: the glass microspheres of 300-350 mesh refractive index 1.90 are first pickled with oxalic acid, then add 5% silane coupling agent of glass microsphere weight after drying, add glass microsphere weight 1% sodium dodecyl sulfonate, stir and mix evenly, and dry completely, so that the microbeads and resin have better compatibility, play a role in wetting and reducing surface tension. The reflective film layer 1 is made of BOPET (biaxially oriented polyester) material, which has good transparency, a light transmittance of 90%, and a thickness of 50 μm. Mix 2 parts of glass microspheres treated with surface organic modification with 3 parts of...

Embodiment 2

[0028] The specific production process of the present invention is: the glass microspheres of 450-500 mesh refractive index 1.93 are pickled with tartaric acid first, then add 5% silane coupling agent after drying, 1% sodium dodecylsulfonate, Stir to combine and dry completely. Wherein the reflective film layer 1 is made of BOPET material with a thickness of 52 μm. 2 three parts of glass microspheres treated with surface organic modification and 35 parts of acrylic acid polymerization modified focusing layer resin are stirred evenly at high speed, the stirring speed is 3000-3500 rpm, and the stirring time is 18 minutes; the acrylic acid polymerization modified The solid content of the resin in the focusing layer is controlled at 27%, the viscosity is controlled at 170cP, and 0.5% of silicone oil defoaming and leveling agent is added to the resin. Apply the above mixed material glue on the reflective surface layer 1, the thickness of the wet glue layer is controlled to 180μm-2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com