Method and system for treating silicon tetrachloride by hydrolysis method

A technology of silicon tetrachloride and hydrolysis method, which is applied in the direction of chlorine/hydrogen chloride and chloride preparation, etc., can solve the problems of polluting the ecological environment, high cost, and high energy consumption, and achieve energy saving, equipment simplification, and cost reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

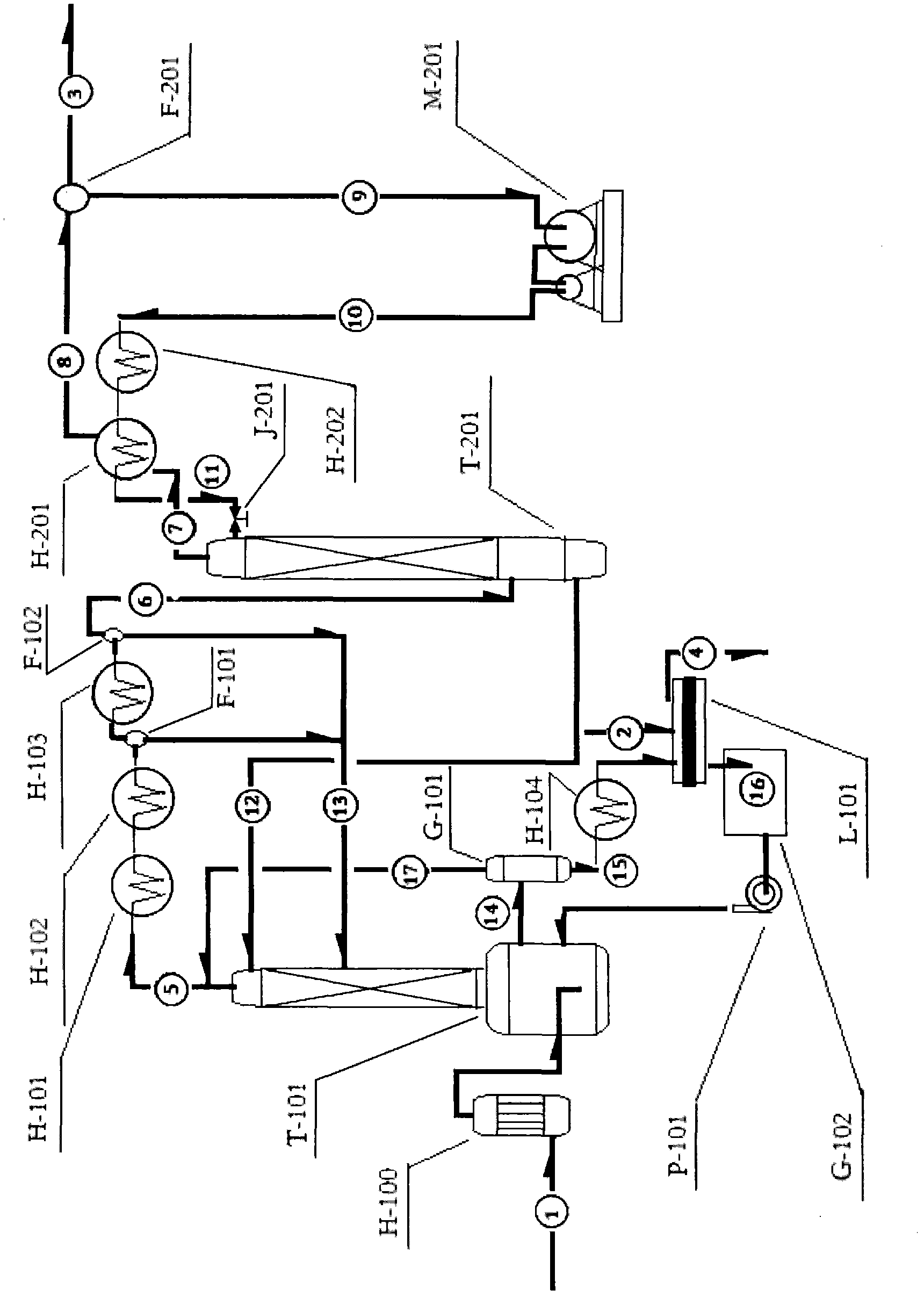

Embodiment 1

[0089] Description of main equipment:

[0090] Reactive distillation tower: bubbling bed reaction section φ800×2000mm; rectification section φ500×5000mm, built with ceramic components;

[0091] Dehydration tower: φ500×6000mm, with ceramic components inside;

[0092] Heat exchange equipment: H-100, made of graphite, heat exchange area 0.6m 2 ;H-101, made of graphite, with a heat transfer area of 9.4m 2 ;H-102, made of graphite, heat exchange area 2.0m 2 ;H-103, made of graphite, heat transfer area 0.7m 2 ;H-104, made of graphite, heat exchange area 17.3m 2 ;H-201, made of stainless steel, heat exchange area 5.0m 2 ;H-202, made of stainless steel, heat transfer area 0.1m 2 ;

[0093] Flow Description:

[0094] Such as figure 1 As shown, the hydrochloric acid solution 16 is pumped from the hydrochloric acid storage tank G-102 into the bubbling bed reaction section of the reaction distillation column T-101 through the hydrochloric acid pump P-101, and the silicon tetrac...

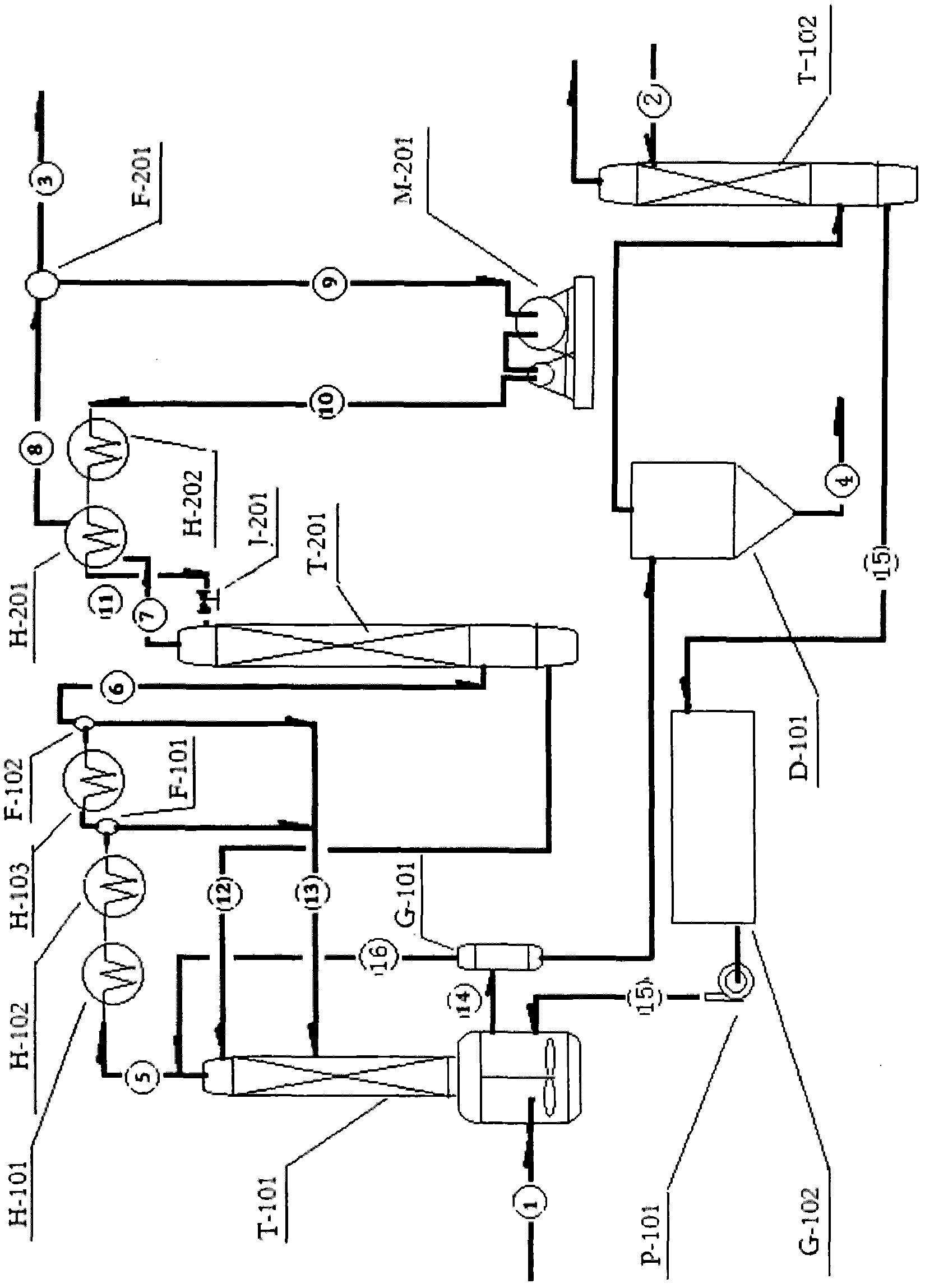

Embodiment 2

[0101] Description of main equipment:

[0102] Reactive distillation tower: stirred bubbling bed reaction section φ260×1500mm; rectification section φ100×400mm, built with ceramic components.

[0103] Dehydration tower: φ500×6000mm, with ceramic components inside;

[0104] Heat exchange equipment: H-100, made of graphite, heat exchange area 0.6m 2 ;H-101, made of graphite, with a heat transfer area of 9.4m 2 ;H-102, made of graphite, heat exchange area 2.0m 2 ;H-103, made of graphite, heat transfer area 0.7m 2 ;H-104, made of graphite, heat exchange area 17.3m 2 ;H-201, made of stainless steel, heat exchange area 5.0m 2 ;H-202, made of stainless steel, heat transfer area 0.1m 2 ;

[0105] Flow Description:

[0106] Such as figure 2 As shown, the hydrochloric acid solution 15 with a concentration of 35.5% is pumped from the hydrochloric acid storage tank G-102 through the hydrochloric acid pump P-101 into the tower still of the reactive distillation column T-101 wit...

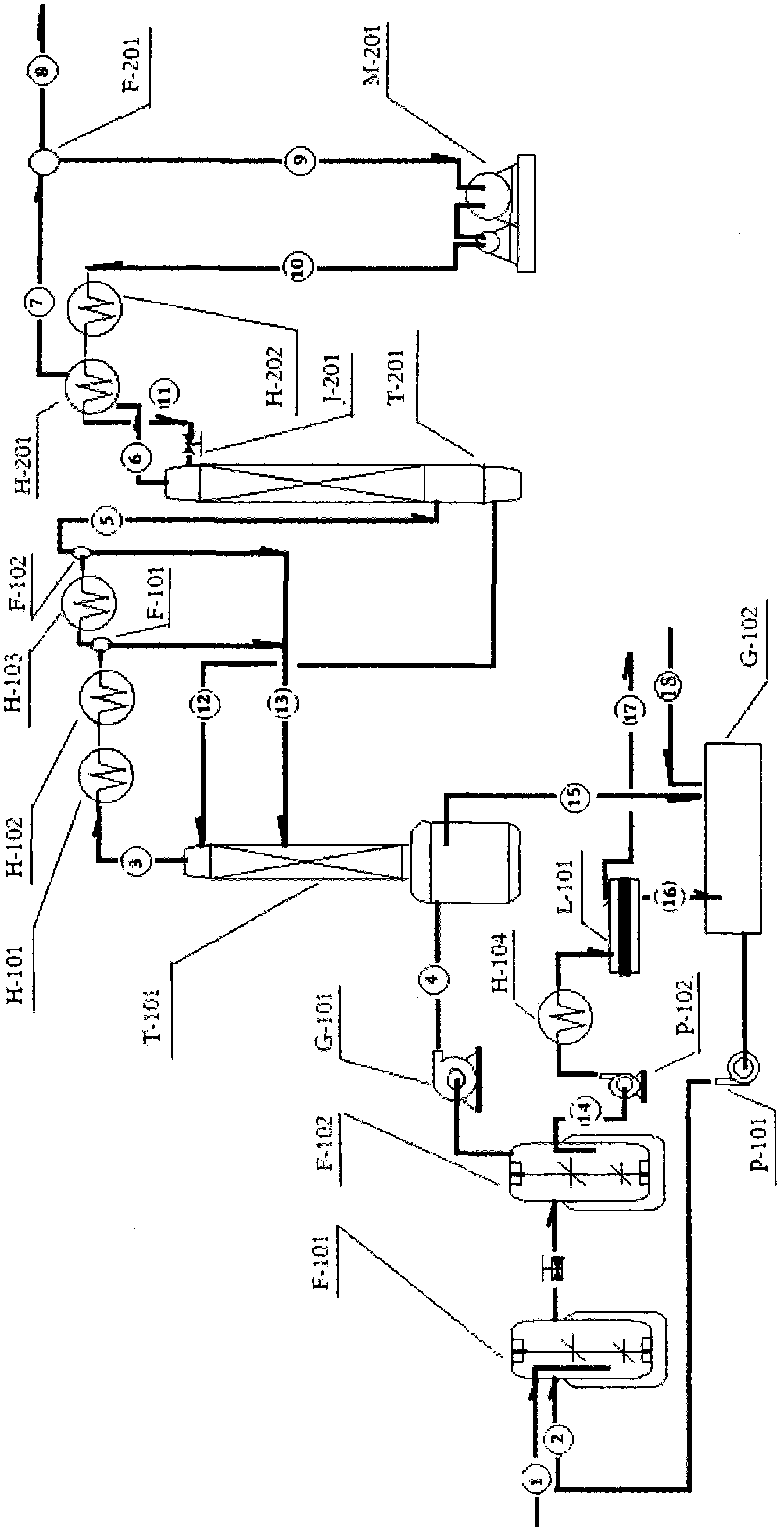

Embodiment 3

[0113] Hydrolysis reaction kettle F-101: φ260×1500mm;

[0114] Analysis tank F-102: φ1000×3500mm;

[0115] Distillation tower T-101: φ100×4000mm;

[0116] Dehydration tower: φ500×6000mm, with ceramic components inside;

[0117] Heat exchange equipment: H-100, made of graphite, heat exchange area 0.6m 2 ;H-101, made of graphite, with a heat transfer area of 9.4m2 ;H-102, made of graphite, heat exchange area 2.0m 2 ;H-103, made of graphite, heat transfer area 0.7m 2 ;H-104, made of graphite, heat exchange area 17.3m 2 ;H-201, made of stainless steel, heat exchange area 5.0m 2 ;H-202, made of stainless steel, heat transfer area 0.1m 2 ;

[0118] Flow Description:

[0119] see image 3 ,described as follows:

[0120] The hydrochloric acid solution 2 with a concentration of 25% is pumped into the hydrolysis reactor F-101 with stirring from the hydrochloric acid storage tank G-102 at a mass flow rate of 4900kg / hr through the hydrochloric acid pump P-101, and the silicon ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com