Preparation method of ethylene glycol antimony

A technology of ethylene glycol antimony and ethylene glycol, applied in the field of preparation of ethylene glycol antimony, can solve problems such as insufficient solubility, and achieve the effects of ensuring filtration effect, reducing steam energy consumption, and reducing reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Laboratory research and development

[0047] According to the technical process of the present invention, the sample produced in the laboratory has carried out product analysis, and the determination of each process parameter has passed through some comparative experiments, and the process is as follows:

[0048] 1. Product sample analysis

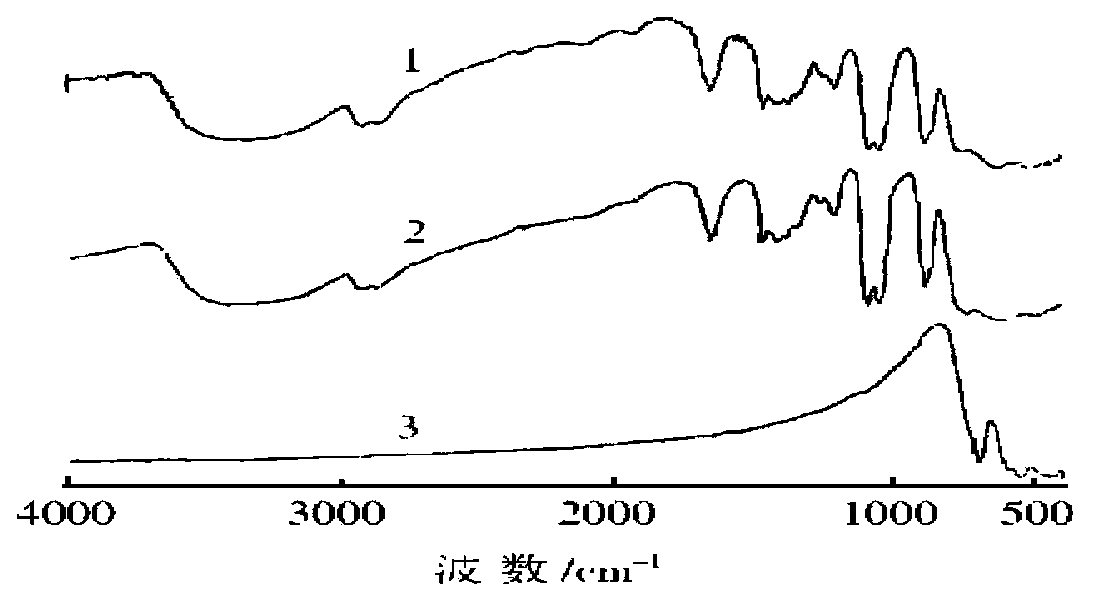

[0049] The product sample was qualitatively analyzed with an infrared spectrometer, and the infrared absorption spectrum of the product was shown in figure 1 shown. Depend on figure 1 Analysis shows that 1085, 1038cm -1 C—O stretching vibration peaks, 2939, 2872cm -1 for CH 2 C—H stretching vibration peak, 1461cm -1 for CH 2 The bending vibration peak of , indicating the presence of ethylene glycol groups in the product; and the reactant Sb 2 o 3 It can be seen from the comparison of the infrared absorption spectra that Sb 2 o 3 Has been converted to antimony glycol.

[0050] 2. Analysis of factors affecting yield and qu...

Embodiment 2

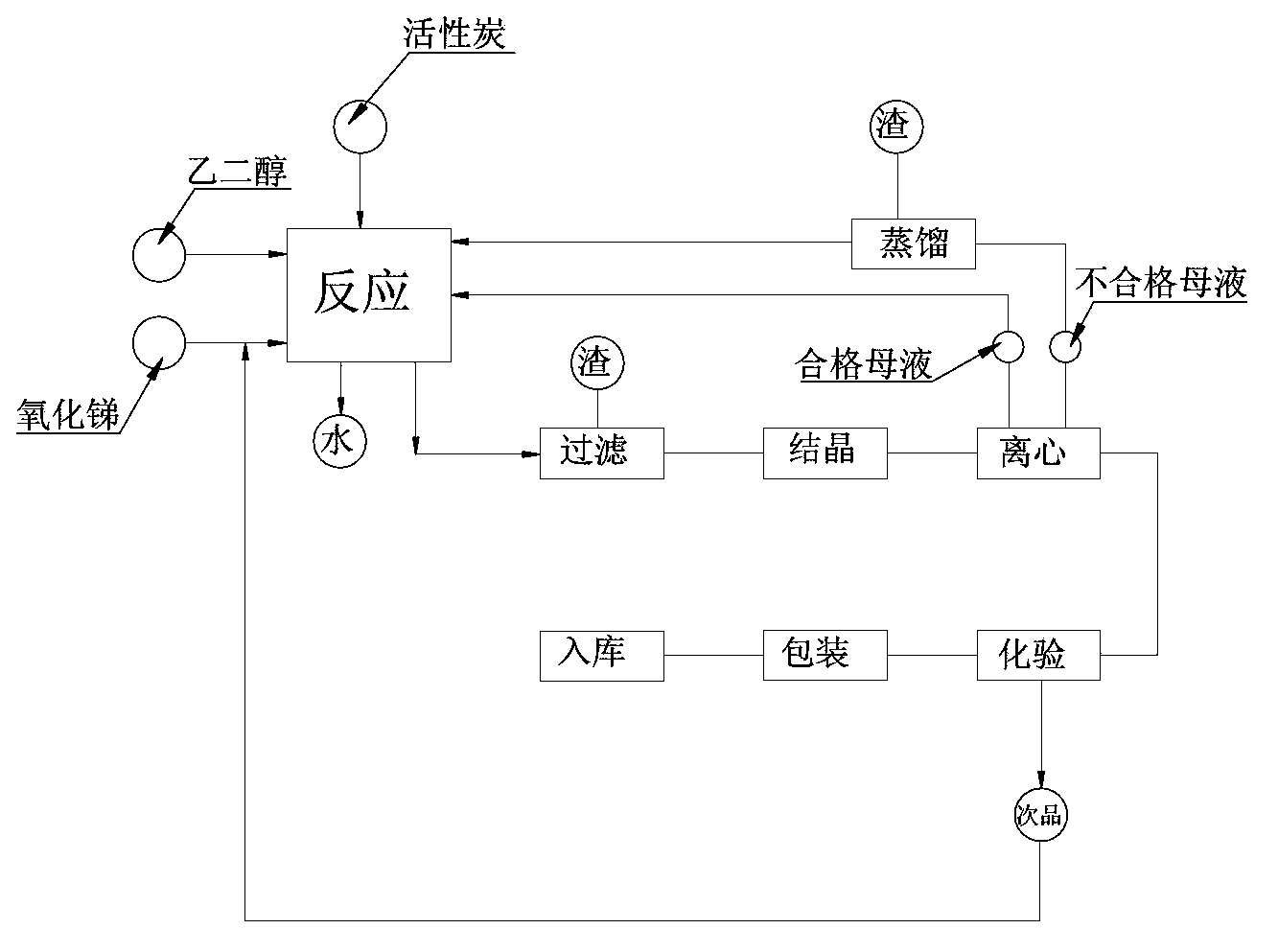

[0075] (2) Industrial production

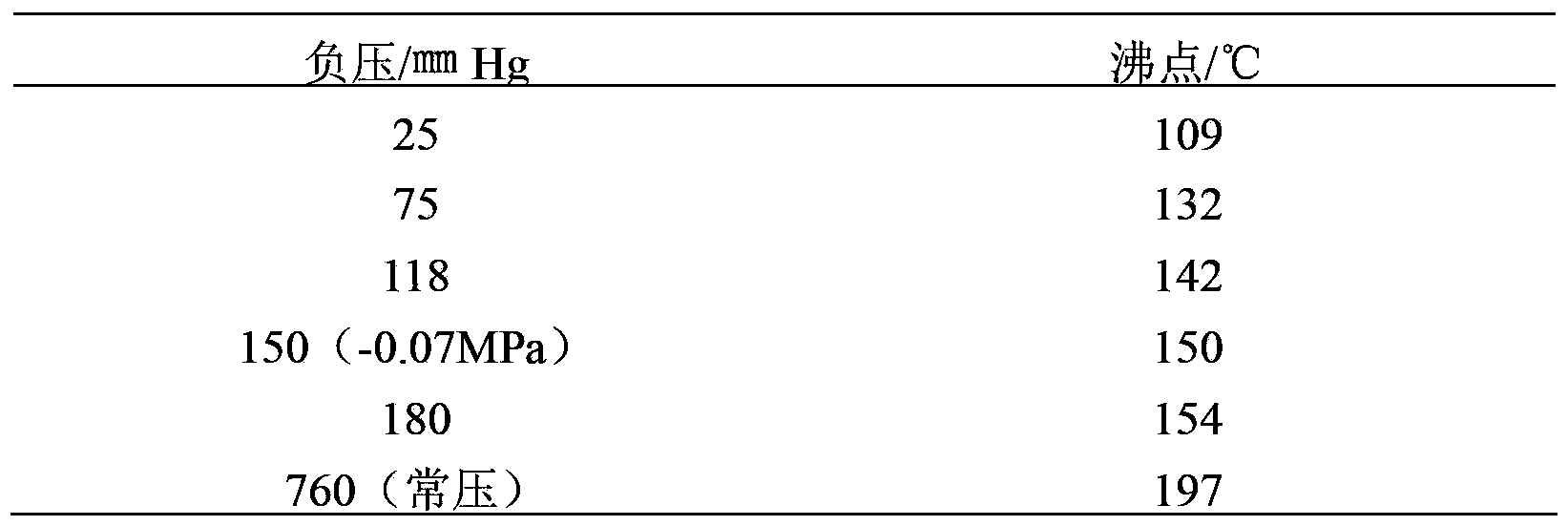

[0076] According to the various process parameters determined above, the weight ratio of feeding materials is 4~7:1 (ethylene glycol: antimony trioxide), the vacuum degree of the reactor is -0.05~-0.07MPa, the reaction temperature is 120~150℃, and the produced water volume is 150 ~300kg / ton Sb 2 o 3 , The dosage of activated carbon is 2~6kg / ton of Sb 2 o 3 , Cooling and crystallization temperature 35-25°C, centrifugal drying rotation speed 800-1200 rpm, continuous production for 15 days, a total of 15 tons of antimony trioxide was invested, 21.3 tons of ethylene glycol antimony was produced, and 12.1 ethylene glycol was consumed tons, 90kg of activated carbon, 17 tons of bituminous coal, and several other materials. The statistics are as follows:

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com