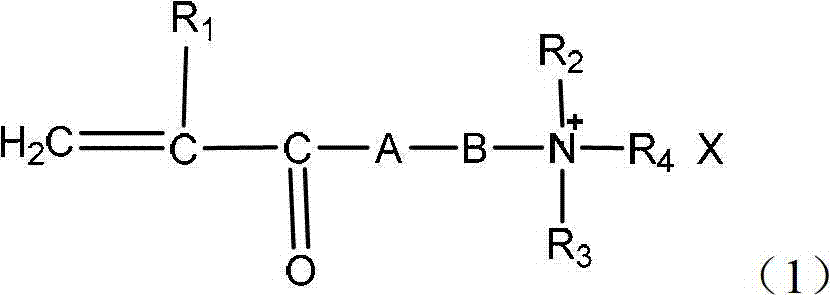

Preparation method of water-in-water type cationic polyacrylamide emulsion

A polyacrylamide, cationic technology, applied in the direction of dehydration/drying/concentrating sludge treatment, etc., can solve the problems of product molecular weight decrease, affecting product quality and performance, and poor solubility, avoiding demulsification and improving stability. , the effect of slowing the viscosity increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

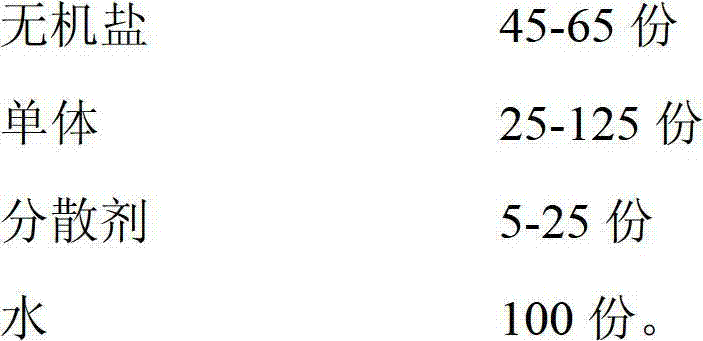

Method used

Image

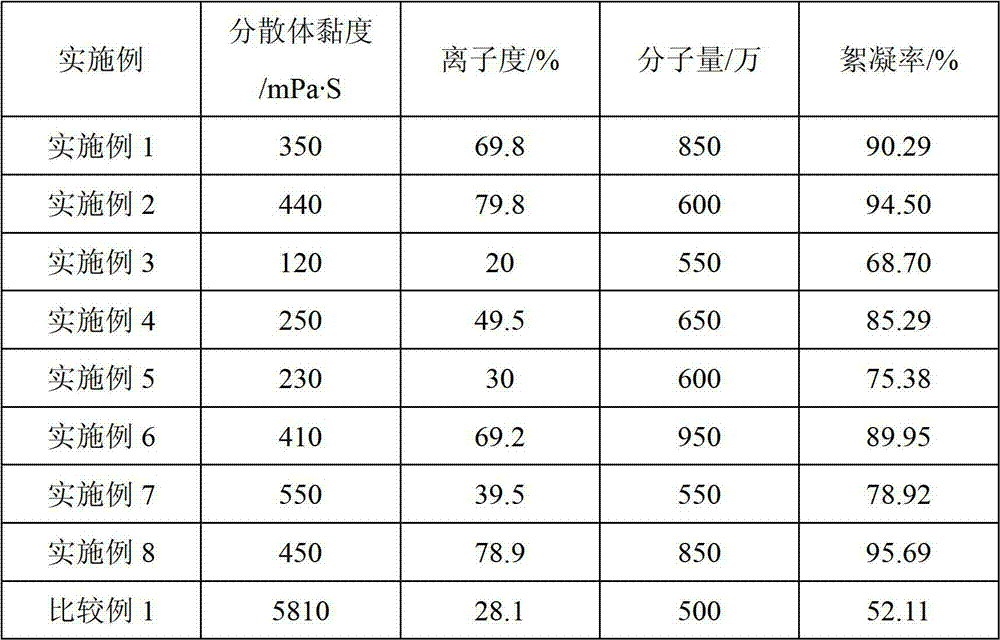

Examples

Synthetic example 1

[0028] Synthesis Example 1 is a synthesis method of the dispersant used in the present invention.

[0029] Synthesis Example 1

[0030] In a reactor equipped with a thermometer, a condenser, a nitrogen gas inlet and a stirring rod, add 100 g of monomer A acryloyloxyethyltrimethylammonium chloride and 398 g of water, raise the temperature to 50 ° C, and pass nitrogen gas for 30 minutes. Add 2 g of azobisisobutylamidine hydrochloride aqueous solution with a concentration of 5%, and stop the reaction after 20 hours of reaction to obtain a polyacryloyloxyethyltrimethylammonium chloride dispersant.

[0031] The synthetic method of polymethacryloyloxyethyltrimethylammonium chloride and polydiallyldimethylammonium chloride is the same as Synthesis Example 1, only need to change monomer A into methacryloyloxyethyl Trimethylammonium chloride and diallyldimethylammonium chloride are enough; the method of synthesizing acrylamide copolymer and methacrylamide copolymer is also the same as...

Embodiment 1

[0034] In a reactor equipped with a thermometer, condenser, nitrogen inlet and stirring rod, add 45 parts of ammonium sulfate, 15 parts of acrylamide, 35 parts of diallyl dimethyl ammonium chloride, polyacryloxyethyl trimethyl 5 parts of ammonium chloride, add 100 parts of water; stir to dissolve all the solids in the system; then raise the temperature to 40°C, and add 2 parts of azobisisobutylamidine hydrochloride solution (mass concentration: 0.5% ), continue to pass nitrogen, and add water within 10 hours to adjust the concentration of ammonium sulfate to 25%, and obtain a uniform milky white liquid after the reaction is completed.

Embodiment 2

[0036] In a reactor equipped with a thermometer, condenser, nitrogen inlet and stirring rod, add 45 parts of ammonium sulfate, 5 parts of sodium chloride, 20 parts of methacrylamide, 80 parts of diallyldimethylammonium chloride, poly Add 10 parts of methacryloyloxyethyltrimethylammonium chloride, add 100 parts of water; stir to dissolve all the solids in the system; then raise the temperature to 35°C, and add 4 parts of hydrogen peroxide solution (mass concentration of 0.5%), 2 parts of ferrous sulfate solution (mass concentration is 0.5%), continue to pass nitrogen, and add water within 8 hours to adjust the total concentration of ammonium sulfate and sodium chloride to 20%, after the reaction, a uniform milky white liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com