Halogen-free flame-retardant polybutylece terephthalate/glass fiber composite and preparation method thereof

A polybutylene terephthalate and composite material technology is applied in the field of high flame-retardant polybutylene terephthalate/glass fiber composite material and its preparation, which can solve the problem of high cost and difficult application , high price and other problems, to achieve the effect of low cost, easy promotion and use, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

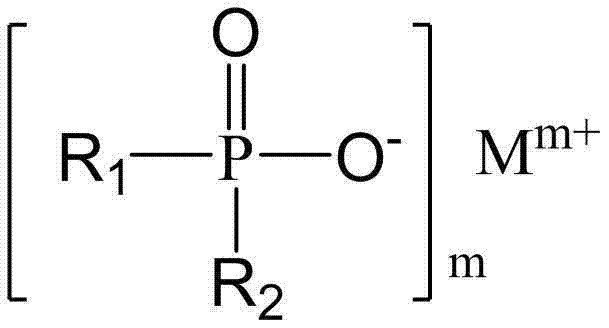

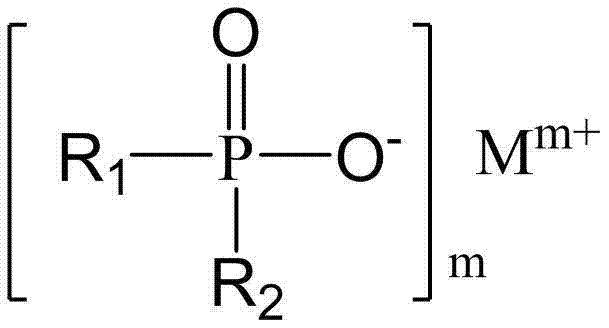

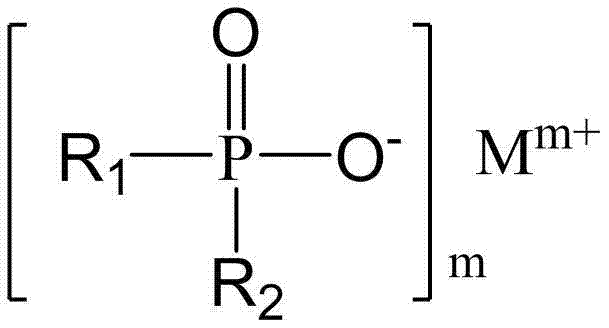

Method used

Image

Examples

Embodiment 1

[0034] Pre-mix 50% PBT, 30% alkali-free glass fiber, 13% aluminum diisobutylphosphinate, and 7% melamine pyrophosphate, adjust the temperature of the twin-screw to 220-250°C, and add the mixture to the twin-screw for extrusion Extruded in the machine, cooled, granulated and dried.

[0035] The oxygen index of the halogen-free flame-retardant PBT / glass fiber composite material is 27.0%, and the UL-94 vertical combustion rating of the 3.2mm and 1.6mm thick sample is V-0.

Embodiment 2

[0037] Pre-mix 50% PBT, 30% alkali-free glass fiber, 15% aluminum diisobutylphosphinate, and 5% melamine pyrophosphate, adjust the temperature of the twin-screw to 220-250°C, and add the mixture to the twin-screw for extrusion Extruded in the machine, cooled, granulated and dried.

[0038] The oxygen index of the halogen-free flame-retardant PBT / glass fiber composite material is 28.0%, and the UL-94 vertical combustion rating of the 3.2mm and 1.6mm thick sample is V-0.

Embodiment 3

[0040] Pre-mix 52% PBT, 30% alkali-free glass fiber, 13% aluminum monoisobutylphosphinate, and 5% melamine pyrophosphate, adjust the temperature of the twin-screw to 220-250°C, and add the mixture to the twin-screw for extrusion Extruded in the machine, cooled, granulated and dried.

[0041] The oxygen index of the halogen-free flame-retardant PBT / glass fiber composite material is 29.0%, and the UL-94 vertical combustion rating of the 3.2mm and 1.6mm thick sample is V-0.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com