Hydrophobic coating material and method for manufacturing the same

A technology for antifouling paint, manufacturing method, applied in the direction of antifouling/underwater paint, coating, paint containing biocide, etc., can solve the problem of incompatibility, poor weather resistance and hardness of polyurethane, difficult to maintain hydrophobicity Properties and other issues, to achieve the effect of increasing application, good coating, and reducing VOC value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

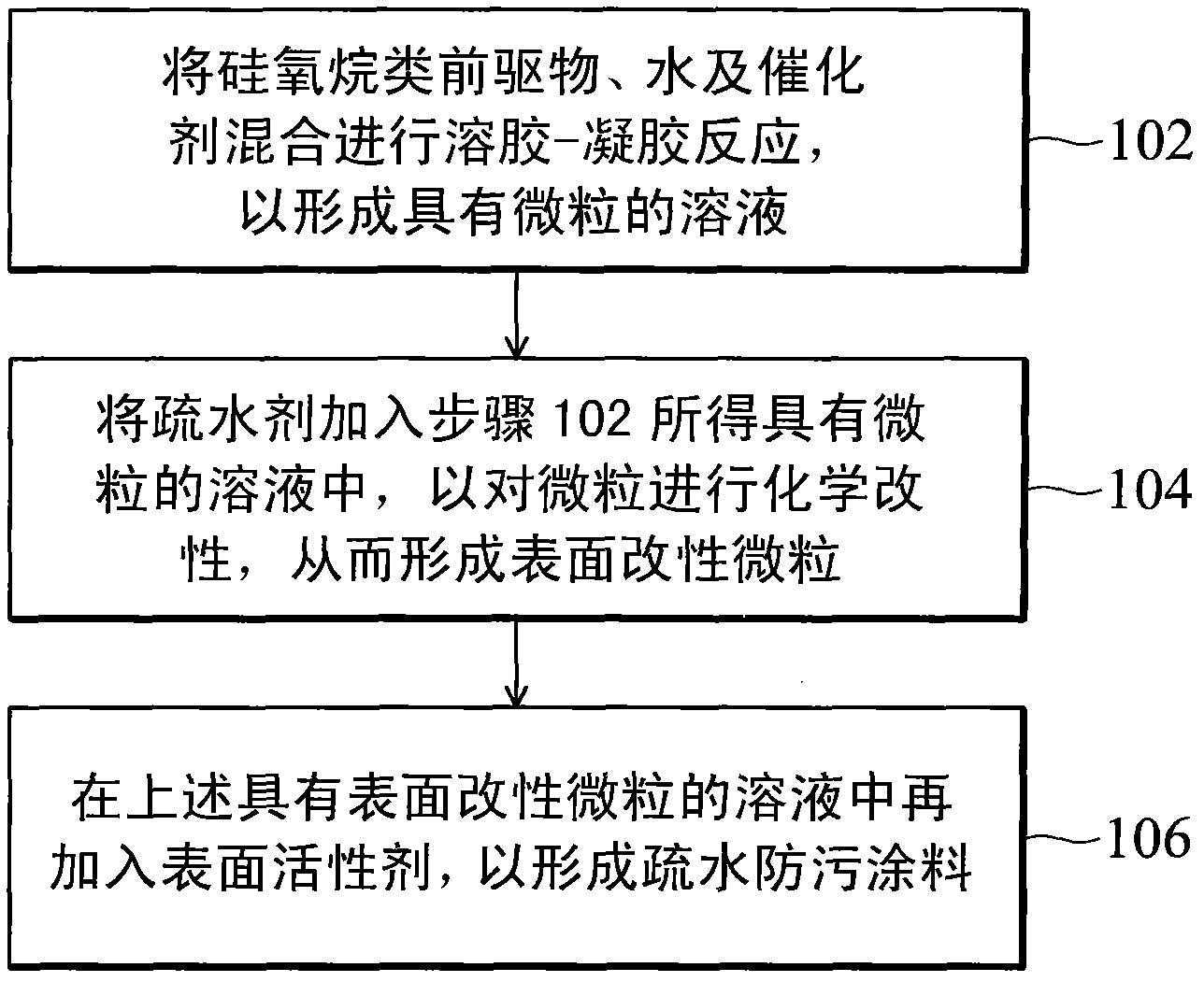

[0034] [Example 1-8] Formation of hydrophobic and antifouling materials

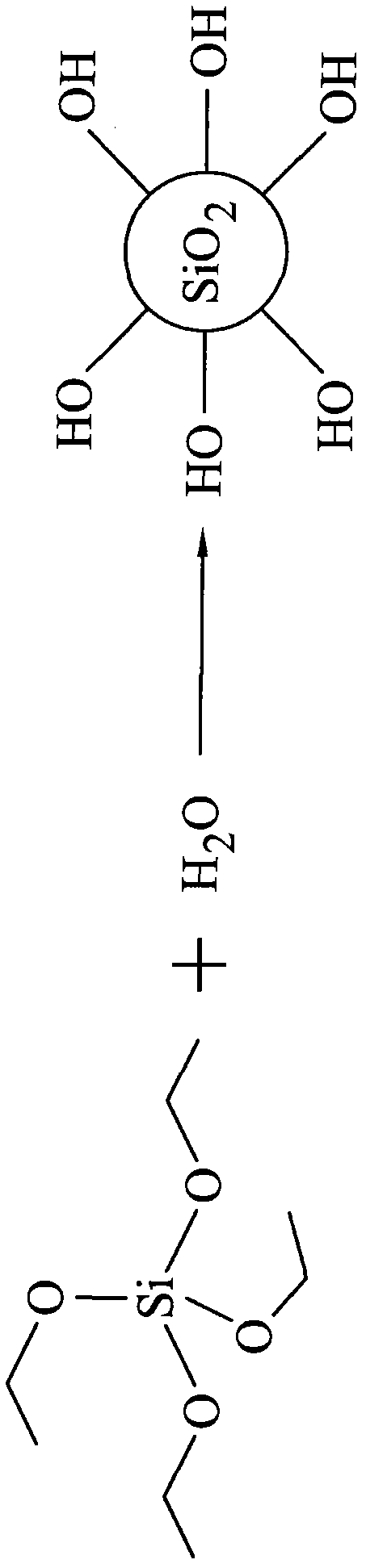

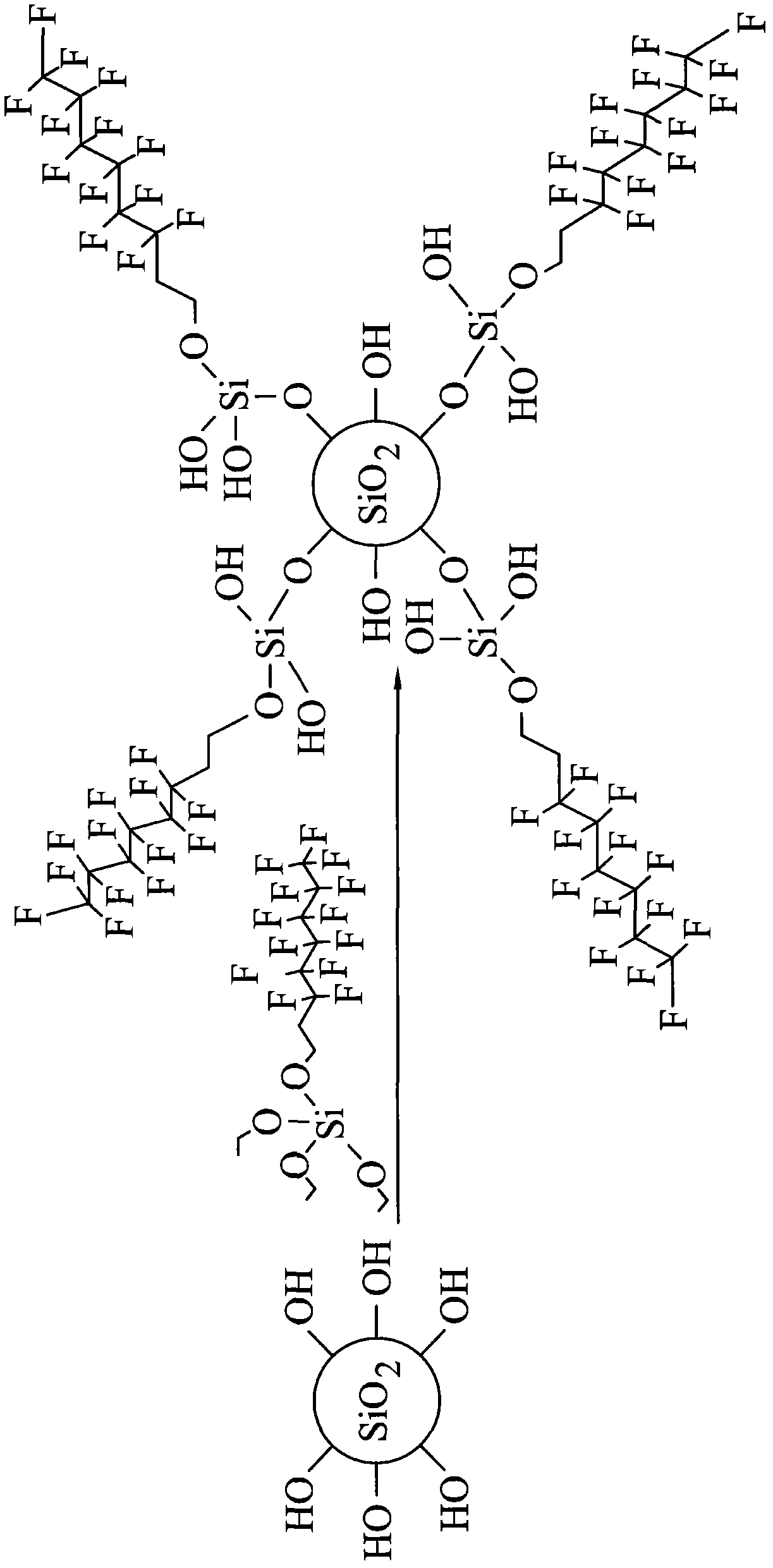

[0035] 0.8 g of tetraethyl orthosilicate (TEOS), 0.277 g of water, and 0.32 g of 0.1N HCl were mixed and reacted at room temperature for 3 hours to obtain a solution containing microparticles. Then, 0.8 g of 1H, 1H, 2H, 2H-perfluorodecyltriethoxysilane (F-8261, Degussa) was added and reacted at room temperature for 2 hours to modify the microparticles. Finally, 0.0384g of anionic surfactant sodium dodecylsulfonate (Sodium dodecyl (ester) sulfate; SDS) was dissolved in 24.94 grams of water, then added to the modified solution, and reacted at room temperature 12 hours to obtain a stable hydrophobic antifouling coating in the aqueous phase. Then, the above-mentioned hydrophobic antifouling coating was coated on the glass substrate, and baked at 120° C. for 30 minutes and then cooled. The water contact angle was measured to be 116°.

[0036] Other examples and comparative examples are shown in Table 1, whe...

Embodiment 9

[0044] [Example 9] The volatile organic compound (VOC) value of the hydrophobic antifouling coating film

[0045] The volatile organic compound (VOC) values of Example 1 and Comparative Example 1 were measured, and the results are shown in Table 2 below. Among them, the calculation method of VOC is ISO 11890-2 (10.3Method 2).

[0046] Table 2

[0047]

[0048] Referring to Table 2, compared with the hydrophobic antifouling coating film of Comparative Example 1, no organic solvent is used in the manufacturing process of the hydrophobic antifouling coating film formed in Example 1 of the present invention, so the requirement of low VOC value can be achieved, and This VOC comes from the by-product (ethanol) produced by the sol-gel reaction of TEOS. The coating prepared by this synthesis method is an environmentally friendly hydrophobic coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com