Holmium-doped yttrium oxysulfide up-conversion luminescent material as well as preparation method and application thereof

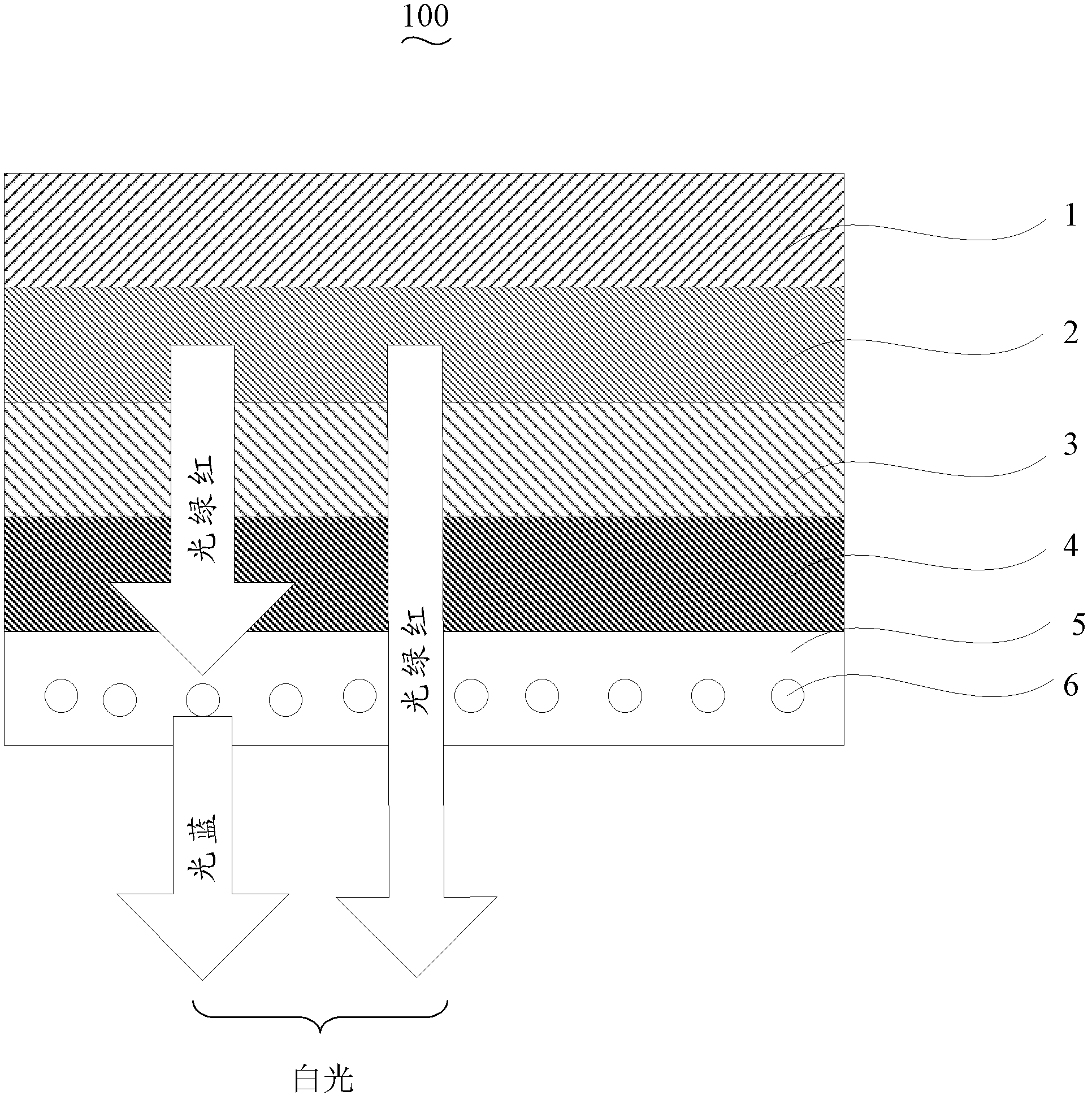

A technology of yttrium oxysulfide and luminescent materials, which is applied in the fields of luminescent materials, chemical instruments and methods, semiconductor/solid-state device manufacturing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The preparation method of the above-mentioned holmium-doped yttrium oxysulfide up-conversion luminescent material comprises the following steps:

[0024] Step S11, weighing Y 2 o 3 、Ho 2 o 3 , refers to sulfur (S) and Na 2 CO 3 Powder, where Y 2 o 3 、Ho 2 o 3 , S, Na 2 CO 3 The molar ratio is (0.95~0.99):(0.01~0.05):1:1.5.

[0025] In this step, Y 2 o 3 、Ho 2 o 3 , S, Na 2 CO 3 The molar ratio is 0.97:0.03:1:1.5.

[0026] Step S13, mixing the powder weighed in step S11 evenly to obtain a precursor.

[0027] In this step, the powder is ground in a corundum bowl for 20 minutes to 60 minutes to obtain a homogeneously mixed precursor, preferably for 40 minutes.

[0028] Step S15 , under a reducing atmosphere, burn the precursor at 800° C. to 1000° C. for 0.5 to 5 hours, then cool to 100° C. to 500° C., and keep warm for 0.5 to 3 hours to obtain a powder product.

[0029] Preferably, the precursor is fired at 800° C. for 3 hours.

[0030] Preferably, it ...

Embodiment 1

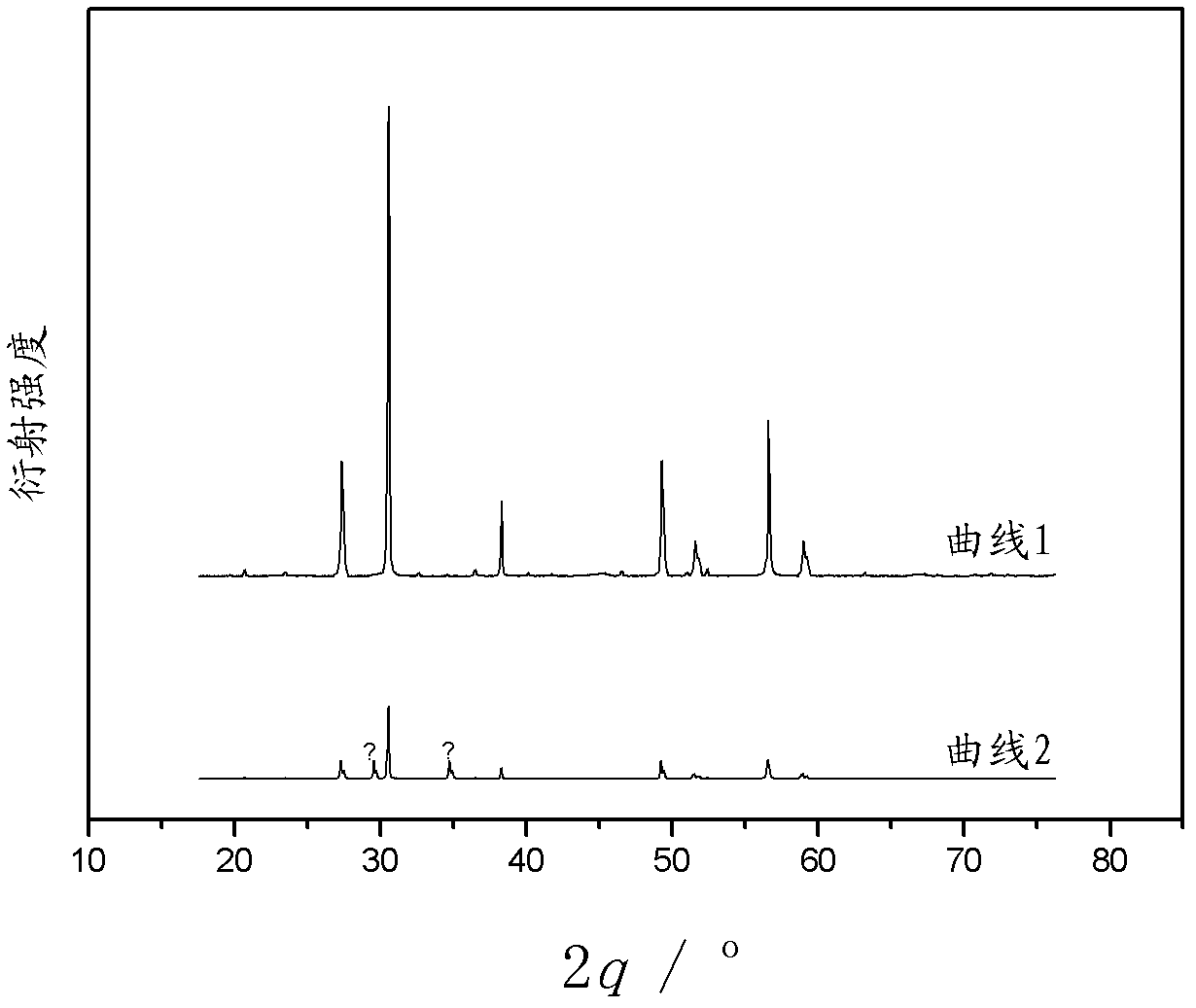

[0040] Choose powder with a purity of 99.99%, Y 2 o 3 , Ho 2 o 3 , elemental S and Na 2 CO 3 Flux powder, its mass is 2.318g, 0.189g, 1.074g, 0.836g respectively. Grind them in a corundum mortar for 40 minutes to make them evenly mixed, and then burn for 3 hours at 800°C in argon-hydrogen mixed gas containing 5% hydrogen as a protective gas. Then cool to 250°C and keep it warm for 2 hours, then naturally cool to room temperature, take out the powder, soak in hot dilute hydrochloric acid for 1 hour, then rinse with deionized water until neutral, filter and dry to obtain the final phosphor.

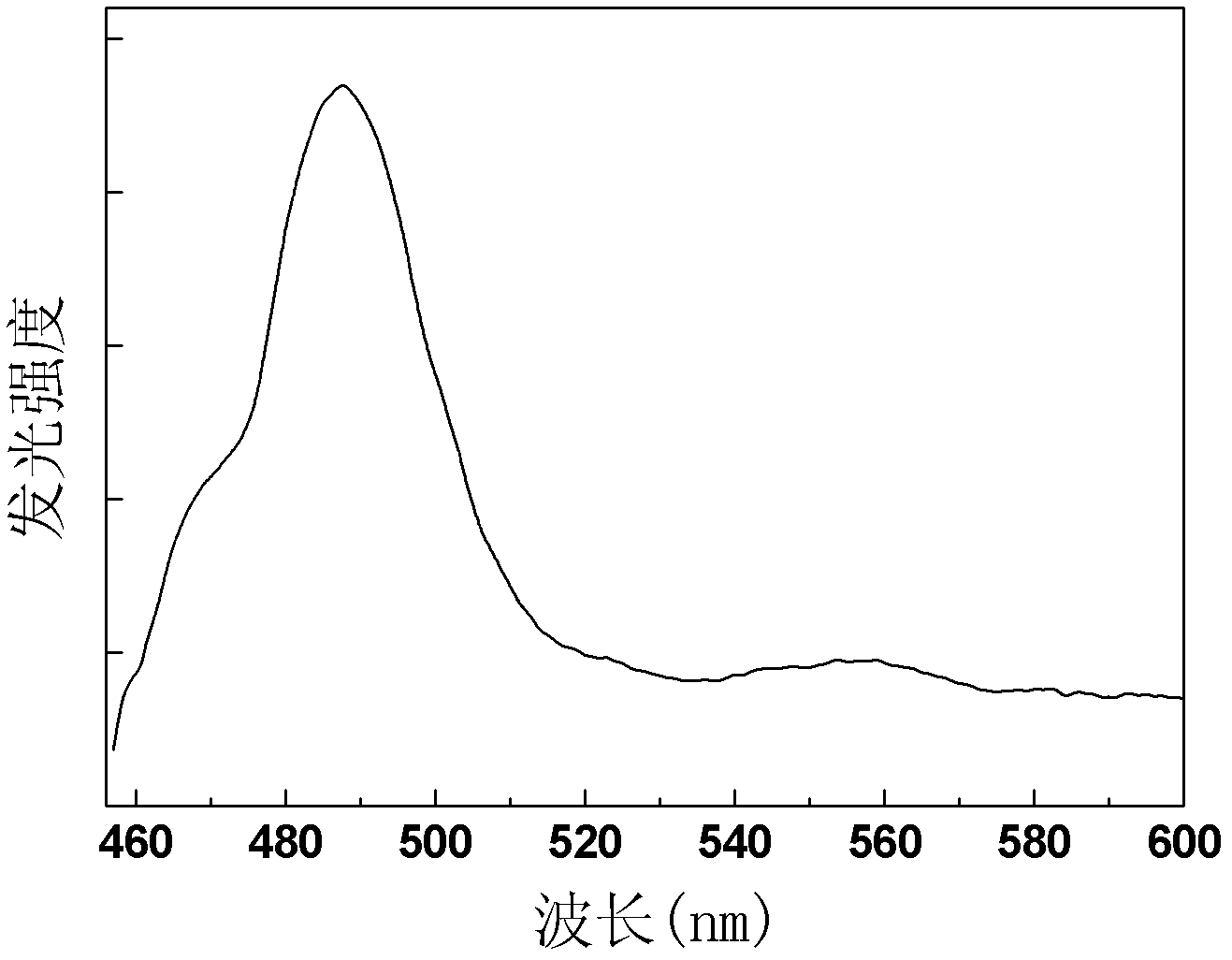

[0041] see figure 2 , figure 2 Shown is the photoluminescence spectrum of the obtained holmium-doped yttrium oxysulfide up-conversion luminescent material. Depend on figure 2 It can be seen that the excitation wavelength of the holmium-doped yttrium oxysulfide up-conversion luminescent material obtained in this embodiment is 640nm, and in the 490nm wavelength region by Ho 3+ io...

Embodiment 2

[0044] Choose powder with a purity of 99.99%, Y 2 o 3 , Ho 2 o 3 , elemental S and Na 2 CO 3 Flux powder, its mass is 2.196g, 0.378g, 1.103g, 0.858g respectively. Grind in a corundum mortar for 20 minutes to make them evenly mixed, and then burn for 5 hours at 500°C in argon-hydrogen mixed gas containing 5% hydrogen as a protective gas. Then cool to 100°C and keep it warm for 0.5 hours, then naturally cool to room temperature, take out the powder, soak in hot dilute hydrochloric acid for 1 hour, then rinse with deionized water until neutral, filter and dry to obtain the final phosphor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com