Pre-stored stress rib with composite structure and manufacturing method thereof

A technology of pre-existing stress tendons and composite structures, applied in the direction of structural elements, building structures, building components, etc., can solve problems such as low elongation rate, and achieve the effects of preventing cracking, increasing durability, and increasing crack resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

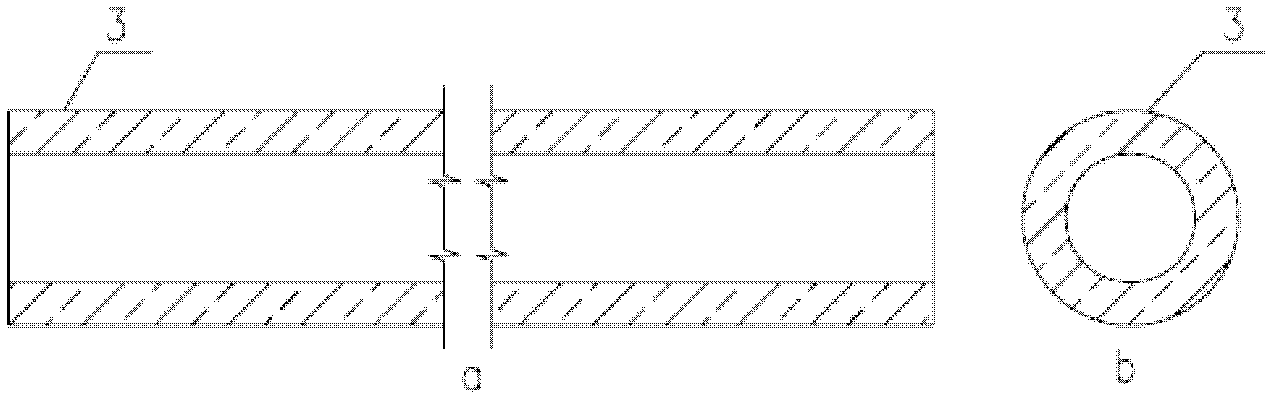

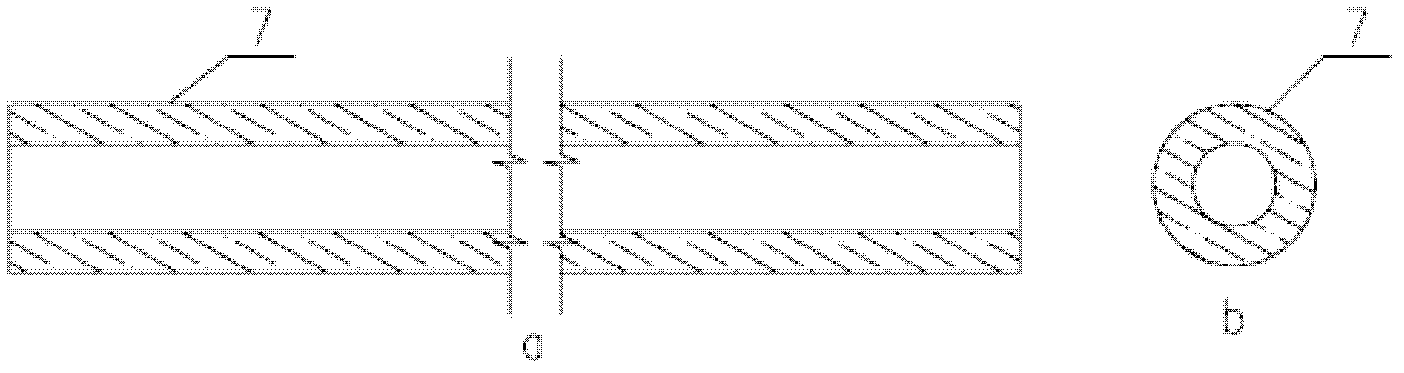

[0158] Such as Figure 21A As shown, first, a method of manufacturing the CFRP (carbon fiber reinforced composite material) outer pipe 3 will be described. Figure 15 It is a schematic diagram of the manufacturing method of the fiber bundle outer tube 3 and the fiber bundle mandrel 4 . Arrange several pitch-based continuous carbon fibers in parallel in the same direction on the mandrel, or weave and twist on the mandrel, soak in the mixed glue solution with 50% weight of phenolic resin and ethanol, and pultrude through the forming hole , heated at 300°C for 1 hour to cure the phenolic resin to make a CFRP outer tube. The medium of the CFRP outer tube can also use polyimide. The inner and outer surfaces of the CFRP outer tube can be treated to be uneven to increase its bonding force with the base material and the inner structure of the tube. During the manufacturing process of the CFRP outer tube, the inner diameter and outer diameter of the CFRP outer tube 3 are changed by ...

Embodiment 2

[0166] The manufacturing method of the CFRP outer tube 3 is the same as that in Embodiment 1.

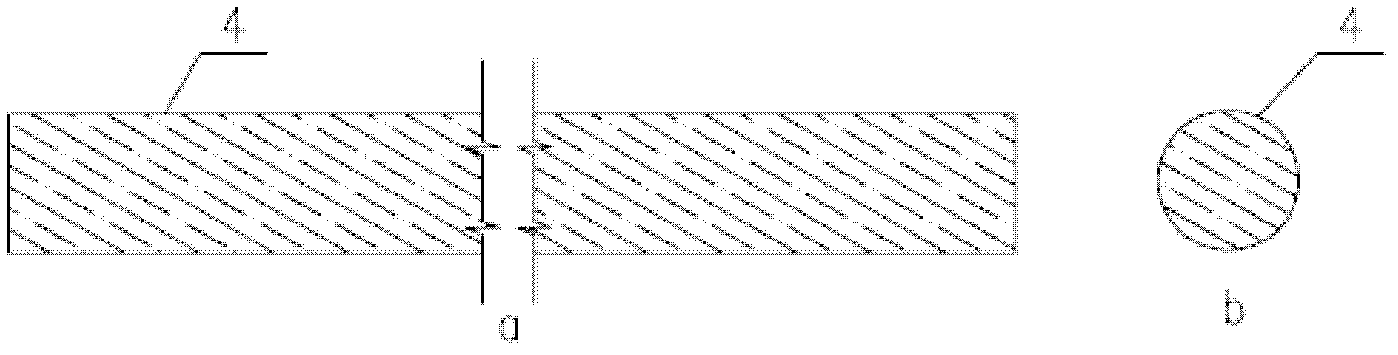

[0167] Next, a method for manufacturing the CFRP (carbon fiber reinforced composite material) mandrel 4 will be described. Such as Figure 15 , several pitch-based continuous carbon fiber bundles arranged in the same direction are soaked in polyimide adhesive, pultruded through forming holes, heated and cured, and made into CFPR mandrel 4 . Soak the conductive heating wire 15 coated with insulating varnish in the epoxy resin glue solution with curing agent, and then weave the mesh conductive heating wire 15 on the surface of the CFPR mandrel 4 as a heating element, or wind it on the CFPR mandrel The twisted conductive heating wire 15 is used as a heating element, the epoxy resin is cured, and the conductive heating wire 15 is bonded on the surface of the mandrel to form a CFPR mandrel 4 with a heating element.

[0168] If epoxy resin is used as the medium, one method is to soak se...

Embodiment 3

[0172] The manufacturing method of the high-strength steel wire spliced outer tube 3 will be described below. During the forming process of high-strength steel wire, the cross-sectional shape of the wire drawing is as follows: Figure 13 11 of them. The outer tube 3 is formed by assembling three tube pieces 11 . The splicing connection method can use modified high-temperature-resistant epoxy resin adhesive 21 or inorganic adhesive to splice the pipes at the splicing seam 12 , or directly wind the silk thread to bundle the segments 11 into the outer pipe 3 . In the surface bonding treatment of the spliced outer tube 3, except for the seam surface, other surfaces of the steel wire can be treated with suitable spiral ribs to increase the binding force between the outer tube 3, the base material and the adhesive 5. On the division of the assembled outer tube 3, the outer tube 3 can be assembled from two pieces, or assembled from more pieces. Figure 17 It is a schematic dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com