Sarcosine oxidase affinity medium and method for synthesizing and purifying sarcosine oxidase

A sarcosine oxidase pro- and sarcosine oxidase technology, which is applied in the fields of bioengineering and diagnostic enzyme production, can solve the problems of low protein and activity recovery rate, long purification time, etc., and achieves increased purification efficiency and great economy. Benefit, effect of large industrial application potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

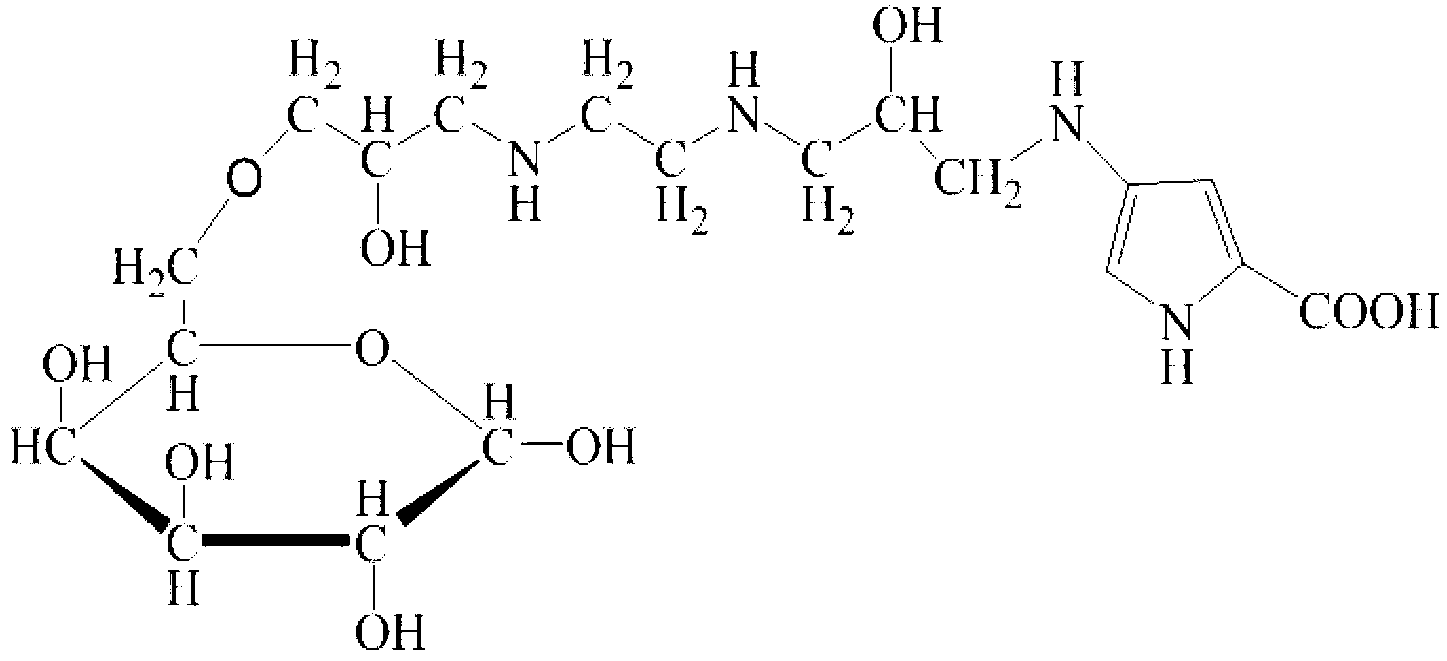

[0037] Embodiment 1: Synthesis and application of Sepharose-4-aminopyrrole-2-carboxylic acid

[0038]Sepharose CL 4 B (100 g) was washed with 10 times the volume of deionized water and dried into a wet cake; suspended in 50 mL activation buffer (0.8 M NaOH, 20% dimethyl sulfoxide, 10% epichlorohydrin ) Shake at 40°C for 2.5 h, then pour it into a glass frosted funnel, wash with 10 times the volume of distilled water each time under suction filtration until the pH of the washing solution reaches neutral, and then drain to form a wet cake. The activated Sepharose CL 4 B medium was suspended in 100 mL of deionized water, ethylenediamine was added at a molar ratio of 1:2, and the gel was kept at 60 °C for 12 h under stirring (200 rpm). Rinse with deionized water. NH 2 -Sepharose CL 4 B was resuspended in 50mL buffer system (0.8 M NaOH, 20% dimethyl sulfoxide, 10% epichlorohydrin) at 40°C for 2.5 h on a shaker, then poured into a glass frosted funnel, Wash with 10 times the volu...

Embodiment 2

[0050] Embodiment 2: Synthesis and application of polychitosan-4-aminopyrrole-2-carboxylic acid

[0051] Polychitosan (100 g) was washed with 10 times the volume of deionized water and dried into a wet cake; suspended in 50 mL activation buffer (0.8 M NaOH, 20% dimethyl sulfoxide, 10% epichlorohydrin ) Shake at 40°C for 2.5 h, then pour into a glass frosted funnel, wash with 10 times the volume of distilled water each time under suction filtration, until the pH of the washing solution is neutral, and then drain to form a wet cake. The activated polychitosan medium was suspended in 500 mL of 0.1M NaOH solution, 20 mL of ethylenediamine solution was added, and the gel was kept at 30 °C for 12 h under stirring (200 rpm). Rinse and dry with deionized water to obtain amino-polychitosan. Amino-polychitosan was suspended in 50 ml buffer system (0.8 M NaOH, 20% dimethyl sulfoxide, 10% epichlorohydrin) and shaken at 40 °C for 2.5 h, then poured into a glass frosted funnel, After wash...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com