Method and device for controlling etching waste liquid with low copper content by using algae

A technology of copper etching and algae, which is applied in the field of algae treatment of low-copper-containing etching waste liquid, can solve problems such as uneven contact, complicated process, and difference in algal powder adsorption, and achieves convenient use and operation, simple device structure, and water protection. resource effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with drawings and embodiments.

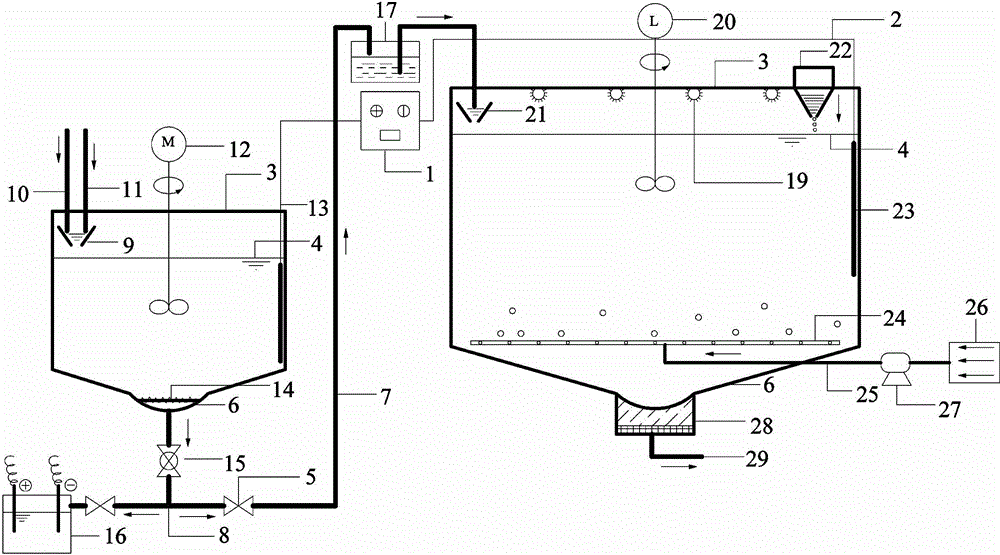

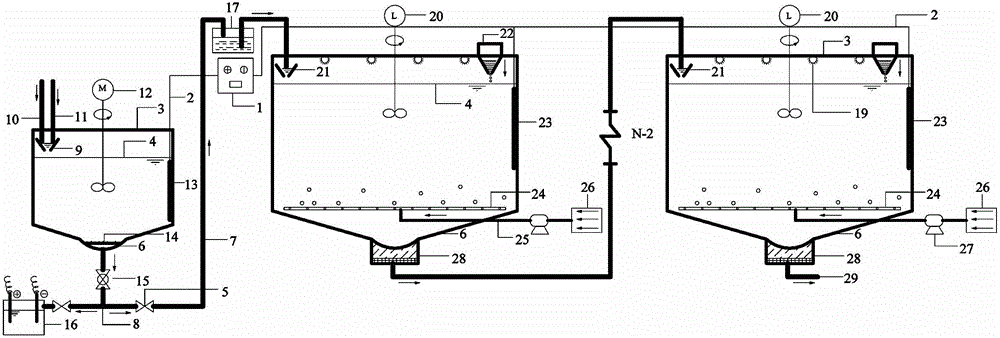

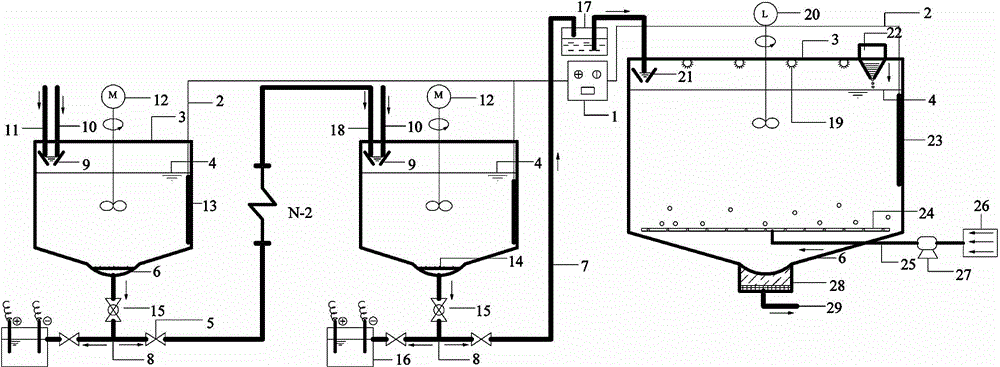

[0027] Such as figure 1 , 2 , 3 and 4, the present invention is composed of algae powder adsorption-analysis chamber and algae cultivation chamber connected by liquid pipeline 7, algae powder adsorption-analysis chamber and algae cultivation chamber respectively have N sub-chambers, and N is a natural number greater than or equal to 1 , when N is a natural number greater than 1, the sub-chambers are connected in series through liquid pipes.

[0028] Figure 5 Shown is a schematic diagram of the structure of the algae powder adsorption-analysis sub-chamber, a bracket 3 is installed on the top of the bracket, a medium-speed impeller agitator 12 is installed on the upper part of the bracket, an etching waste liquid inlet 9 is installed on the lower part of the bracket, and the first temperature control regulator 13 is installed on the lower part of the liquid level line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com