A treatment method for circulating water and sewage to be reused in power plants

A treatment method and technology of circulating water, applied in the directions of water/sewage multi-stage treatment, water/sludge/sewage treatment, general water supply saving, etc. The problems such as the decrease of permeate production water volume, etc., can achieve the effect of reducing the efflux of wastewater, reducing alkalinity and hardness, and reducing the hardness of influent water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

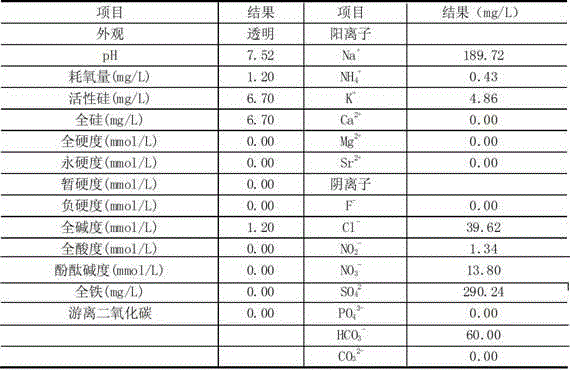

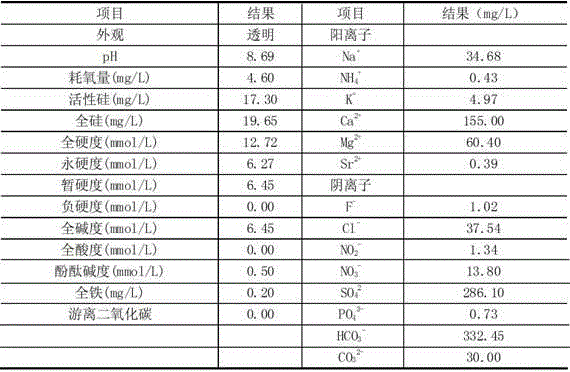

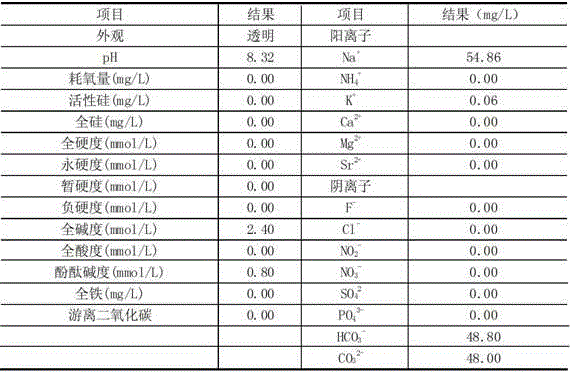

[0026] (1) Set the water volume to 200m 3 / h of circulating water sewage is injected into the mechanical agitation acceleration clarification tank, and its hardness value and alkalinity value are measured to be 12.72mmol / L and 6.45mmol / L respectively, and sodium hydroxide is added to the above-mentioned circulating water to soften, so that the hydrogen and oxygen in the circulating water The root concentration is 0.1-0.4mmol / L, then add polyferric sulfate and polyacrylamide to the softened circulating water for coagulation and clarification treatment, the addition amount of polyferric sulfate and polyacrylamide is 40mg / L and 1.0mg respectively / L; The mechanical agitation acceleration clarification tank adopts a Ф14300 mechanical agitation acceleration clarification tank, and the design output is 180-350m 3 / h. See Table 1 for the water quality of the power plant's circulating water and sewage.

[0027] Table 1 Water quality of circulating water and sewage

[0028]

[0...

Embodiment 2

[0040] The hardness value and alkalinity value of circulating water sewage in this embodiment are 14.20mmol / L and 6.50mmol / L respectively, add sodium hydroxide to soften, make the concentration of hydroxide in circulating water be 0.1-0.4mmol / L; The addition amounts of polyferric sulfate and polyacrylamide were 20 mg / L and 0.6 mg / L respectively; other steps were the same as in Example 1. The water quality of the reverse osmosis produced water in this embodiment also meets the reuse standard.

Embodiment 3

[0042] In this embodiment, the hardness value and alkalinity value of the circulating water sewage are 13.50mmol / L and 7.20mmol / L respectively, and sodium hydroxide is added for softening, so that the concentration of hydroxide in the circulating water is 0.1-0.4mmol / L; The addition amounts of polyferric sulfate and polyacrylamide were 10 mg / L and 2 mg / L respectively; other steps were the same as in Example 1. The water quality of the reverse osmosis produced water in this embodiment also meets the reuse standard.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com