Film plating device and method for preparing TCO (Transparent Conducting Oxide) glass online by floating method

A coating device and glass technology, applied in the field of float glass processing, can solve the problems of unstable production process, weak film firmness, short service life, etc., and achieve low production cost, easy maintenance, and good wear resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

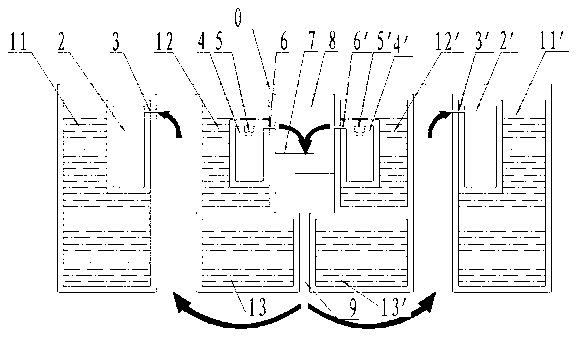

[0024] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0025] Such as figure 1 As shown, the coating device of the present invention for preparing TCO glass by float method on-line is located in the tin tank B of the float glass production line; it includes a coating reactor A fixedly mounted below the top plate, surrounded by wall plates and in a rectangular parallelepiped structure; The coating reactor A is suspended in the tin tank B of the float glass production line through the cantilever C fixed on its top plate, and its lower part is open and directly above the glass conveyor belt passing through the tin tank B; the coating reactor The length of A is the same as the width of this glass conveyor belt.

[0026] Wherein, the coating reactor A is suspended in the temperature range of 630-650° C. in the tin bath B.

[0027] Such as figure 2As shown, the coating reactor of the present inven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com