Fluorescent and flame retarded functionalization hydrotalcite and preparation method thereof

A hydrotalcite and functionalization technology, applied in the field of functionalized hydrotalcite-like and its preparation, can solve the problems of poor compatibility between inorganic hydrotalcite-like and polymer materials, high price of ionic liquid, etc., and achieve light-transfer intensity and flame-retardant performance Improvement, cost reduction, simple equipment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

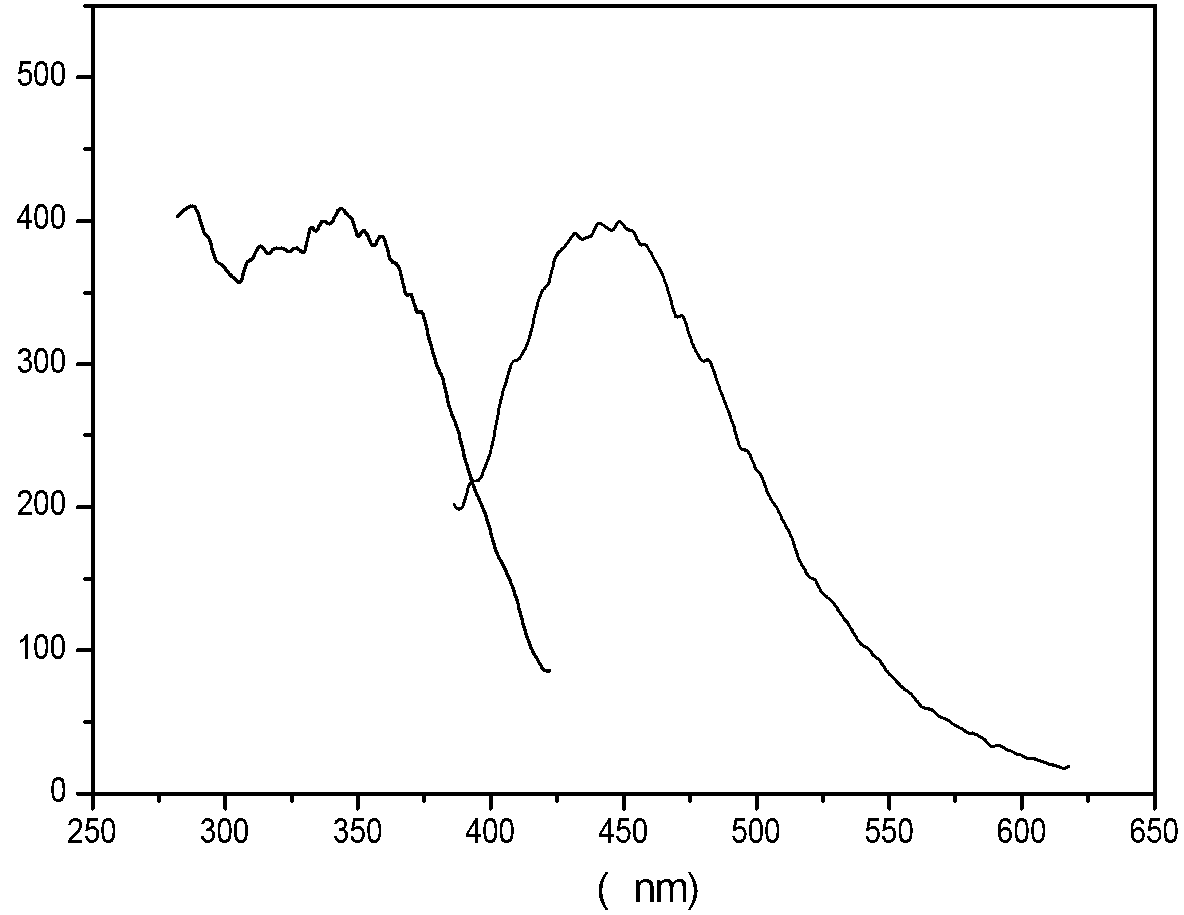

Embodiment 1

[0026] Prepare 0.5mol / L Zn(NO 3 ) 2 and 0.25mol / L Al(NO 3 ) 3Aqueous solution (A); prepare urea aqueous solution (B) containing 3mol / L; mix solution (A) and solution (B) under nitrogen protection, continue magnetic sub-stirring, react for 30 hours, adopt deionized water to centrifugally wash to medium properties, and dried at 50°C for 10 hours to obtain a carbonate intercalated hydrotalcite precursor. The prepared hydrotalcite precursor and ionic liquid 1-butyl-3-methylimidazolium hexafluorophosphate (C) were added to the absolute ethanol solvent for reaction, adding 0.5 g and 3 g of ionic liquid (that is, hydrotalcite precursor 50 g / L, ionic liquid 300 g / L), the stirring speed is 2000 rpm, stirring reaction for 12 hours, standing at 50 ° C for 10 hours, centrifuged washing with absolute ethanol, and drying After 10 hours, the functionalized hydrotalcite-like ionic liquid doped with strong blue fluorescence and flame retardancy was obtained.

Embodiment 2

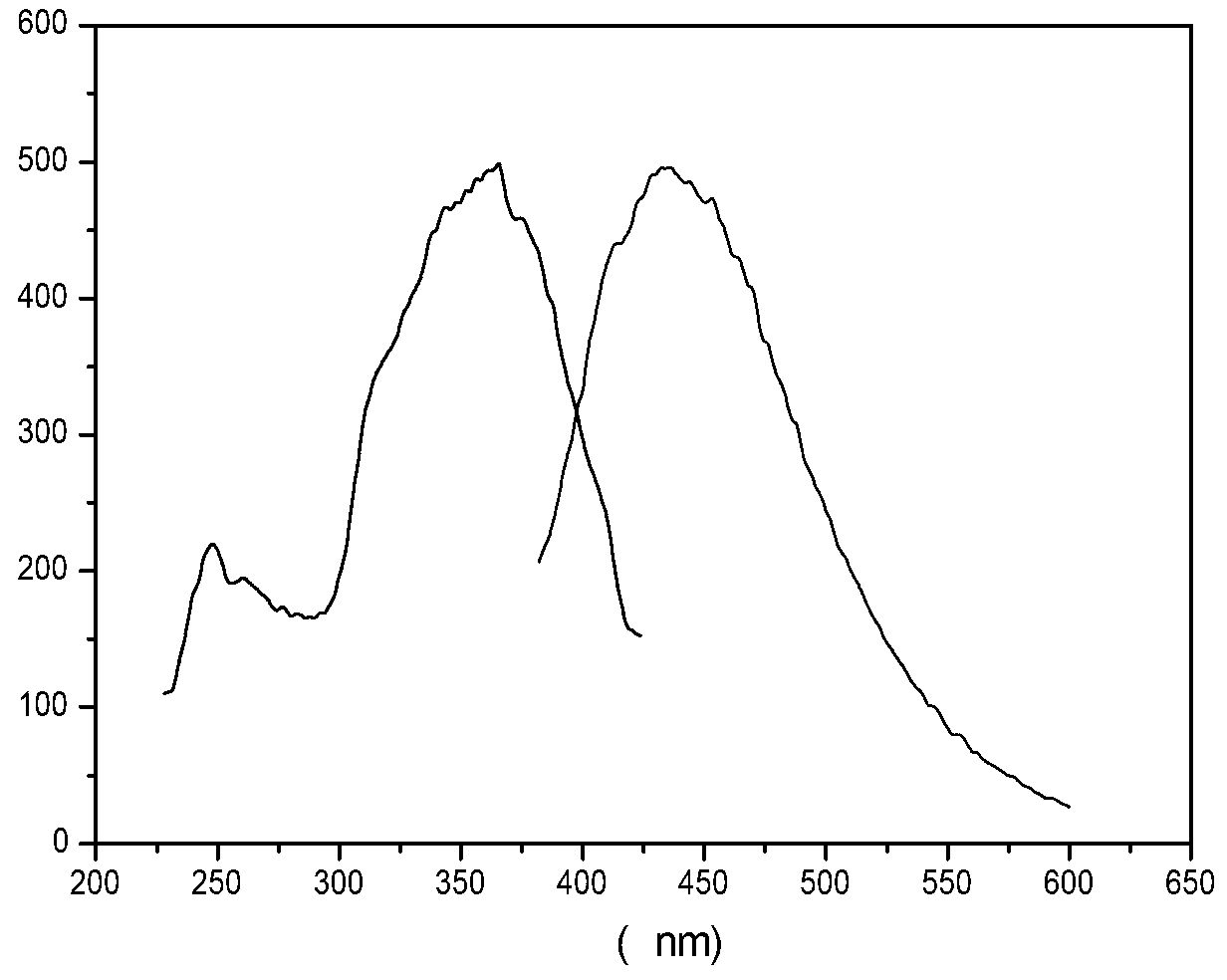

[0028] Prepare 1.0mol / L Co(NO 3 ) 2 and 0.3mol / L Al(NO 3 ) 3 Aqueous solution (A); prepare urea aqueous solution (B) containing 10mol / L; mix solution (A) and solution (B) under the protection of nitrogen, continue magnetic sub-stirring, react for 40 hours, adopt deionized water to centrifugally wash to medium properties, and dried at 50°C for 12 hours to obtain a carbonate intercalated hydrotalcite precursor. Add the prepared hydrotalcite precursor and ionic liquid N-octyl-pyridine hexafluorophosphate (C) into anhydrous ethanol solvent for reaction, add hydrotalcite precursor 100g / L, ionic liquid 450gL, and stir at 2000 RPM, stirring for 12 hours, standing at 50°C for 12 hours, centrifuging and washing with absolute ethanol, and drying for 10 hours to obtain functionalized hydrotalcite-like doped ionic liquid with strong blue fluorescence and flame retardancy.

Embodiment 3

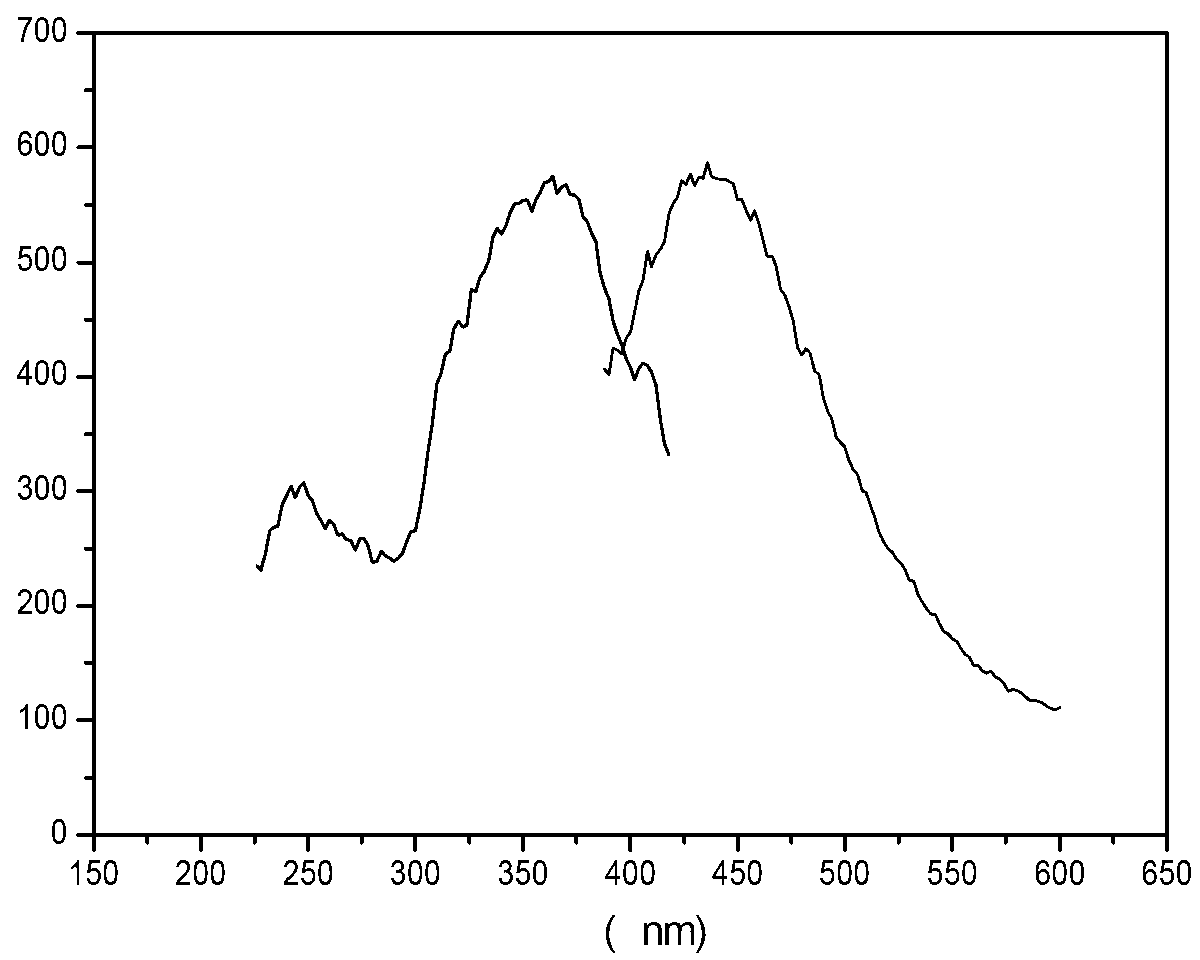

[0030] Prepare 1.0mol / L Zn(NO 3 ) 2 and 0.5mol / L Al(NO 3 ) 3 Aqueous solution (A); prepare urea aqueous solution (B) containing 9mol / L; under nitrogen protection, solution (A) and solution (B) are mixed, and the magnetic sub-stirring is continued, reacted for 30 hours, and then centrifugally washed with deionized water to medium properties, and dried at 50°C for 10 hours to obtain carbonate intercalated hydrotalcite. Add the prepared hydrotalcite precursor and ionic liquid 1-ethyl-3-methylimidazolium ethyl sulfate salt (C) into anhydrous ethanol solvent for reaction, add 80gL of hydrotalcite precursor and 400g / L of ionic liquid, The stirring speed is 3000 rpm, stirring reaction for 12 hours, standing at 60°C for 10 hours, centrifugal washing with absolute ethanol, and drying for 10 hours to obtain a functionalized ionic liquid doped with strong blue fluorescence and flame retardant properties. Hydrotalcite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com