A kind of fixed bed heavy oil hydrogenation method

A heavy oil hydrogenation and fixed bed technology, which is applied in the fields of hydrogenation treatment process, petroleum industry, hydrocarbon oil treatment, etc., can solve the problems of low activity and inability to effectively improve the hydrogenation performance of the graded catalyst system, and achieve high impurity capacity , Improve operational flexibility and ensure product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

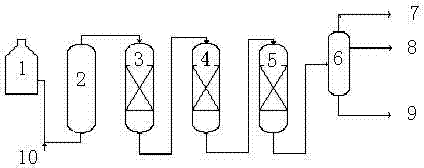

[0027] The serial number 1 is the raw material tank, 2 is the pretreatment reactor, 3 is the hydrodemetallization reactor, 4 is the hydrodesulfurization reactor, 5 is the hydrodenitrogenation reactor, 6 is the distillation unit, 7 is gasoline, and 8 is diesel oil , 9 is hydrogenation tail oil, 10 is hydrogen, and the rest are pipelines.

[0028] Such as figure 1 As shown, the principle process of heavy oil hydrotreating in the present invention is as follows: first, the heavy oil raw material in the raw material tank 1 is mixed with hydrogen 10 and enters the pretreatment reactor 2 in a flow-type manner to carry out hydrodescaling, hydrodemetallization and partial asphaltene addition. Hydrogen conversion reaction; the pretreated stream enters the hydrodemetallization reactor 3, hydrodesulfurization reactor 4 and hydrodenitrogenation reactor 5 in sequence for hydrodemetallization, hydrodesulfurization and hydrodenitrogenation / hydroconversion Reaction; after the reaction, the s...

Embodiment 1

[0037] This example is a hydrogenation test of low-quality residual oil in a fixed-bed heavy oil processing technology. The ebullated-bed reactor for pre-hydrogenation adopts an upflow operation mode, and the rest of the reactors adopt a fixed-bed operation mode in which gas and liquid flow together and flow down. First, the heavy oil raw material in the raw material tank 1 is mixed with hydrogen 10 and enters the pretreatment reactor 2 in an upflow mode for hydrodescaling, hydrodemetallization and partial asphaltene hydroconversion reactions; the pretreatment stream enters the hydrodemetallization in sequence Reactor 3, Hydrodesulfurization Reactor 4 and Hydrodenitrogenation Reactor 5 carry out hydrodemetallization, hydrodesulfurization and hydrodenitrogenation / hydroconversion reactions; after the reaction, the stream passes through distillation unit 6 to obtain 350°C 9. The particulate catalyst used in the pretreatment section is a microspherical molybdenum-nickel catalyst su...

Embodiment 2

[0040] The experimental operation process of this embodiment is basically the same as that of Example 1, except that the particulate catalyst loaded in the inert cage of the reaction section from the stream inlet to one-third of the inlet in the pretreatment reactor contains MoO 3 6wt%, containing 1.2wt% NiO, and a bulk density of 0.65g / cm 3 , with a surface area of 190m 2 / g, the average diameter of the catalyst particles is 1.5mm, which accounts for 40% of the cage volume; the equivalent diameter ratio of the metal cage to the catalyst is 60; the catalyst loaded in the remaining reaction section contains MoO 3 It is 12wt%, containing NiO is 4wt%. Catalyst bulk density is 0.71g / cm 3 , with a surface area of 230m 2 / g, the average diameter of the catalyst particles is 0.8mm, which accounts for 70% of the cage volume, and the equivalent diameter ratio of the metal cage to the catalyst is 100. The reaction conditions and test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| dry point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com