Biodiesel preparation device and preparation method

A technology for biodiesel and preparation equipment, which is applied in the fields of biofuel, petroleum industry, chemical/physical/physicochemical process of energy application, etc. It can solve the problems of insufficient transesterification reaction, slow reaction speed, high cost, etc., and achieve the goal of improving raw materials Conversion rate, good mixing, and cost-effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

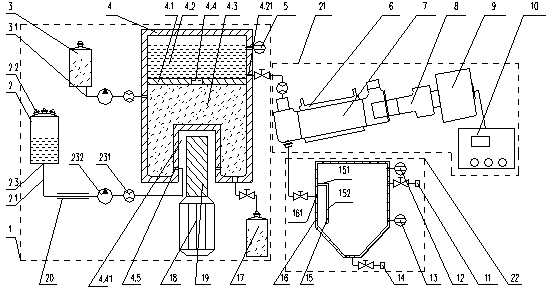

[0029] Combined with the accompanying drawings figure 1 , the biodiesel preparation device includes a magnetic stirring mechanism 1, an ultrasonic esterification reaction mechanism 21 and a liquid phase separator 16, and the magnetic stirring mechanism 1 includes a stirring tank 4, a vertical circular permanent magnet 19, a magnetic ionic liquid storage tank 3 and Raw material storage tank 2, a layered baffle 4.1 is provided in the middle of the mixing tank 4, and the layered baffle 4.1 separates the mixing tank into upper and lower mixing chambers, and the middle part of the layering baffle is provided with a through hole connecting the upper and lower mixing chambers 4.4. The bottom of the lower mixing chamber is concave to form a cylindrical cavity 4.41. The vertical circular permanent magnet is rotatably placed in the concave and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com