Method of plating ZnO film on surface of metal material

A technology of metal materials and thin films, which is applied in the field of material surface modification, can solve problems affecting the judgment of optical signals, variable components, and complex coating preparation processes, etc., to achieve easy visual observation, low industrialization cost, and wear resistance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The method for plating ZnO thin film on the surface of aluminum sheet comprises the following steps:

[0024] (1) The surface of the aluminum sheet is polished, and ultrasonic cleaning is carried out with acetone;

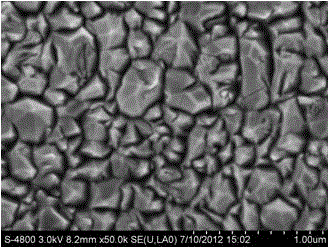

[0025] (2) Put the ultrasonically cleaned aluminum sheet into a magnetron sputtering furnace, and use a zinc oxide target to deposit a ZnO film on the surface of the aluminum sheet. The specific method is as follows: place the zinc oxide at the target position, and The pole spacing is 3 cm; the magnetron sputtering furnace is evacuated to a vacuum degree of 1.0×10 -4 Pa, fill in argon to a pressure of 5 Pa, clean and activate the surface of the aluminum sheet; fill in a mixed gas of oxygen and argon to a pressure of 25 Pa, and the pressure ratio of oxygen and argon in the mixed gas is 1:1 , sputtering power 50W. Adjust the temperature in the magnetron sputtering furnace to 320°C and keep it warm for 1 hour; turn off the power, and evacuate the magnetron sp...

Embodiment 2

[0027] The method for plating ZnO thin film on the surface of aluminum sheet comprises the following steps:

[0028] (1) The surface of the aluminum sheet is polished, and ultrasonic cleaning is carried out with acetone;

[0029] (2) Put the ultrasonically cleaned aluminum sheet into a magnetron sputtering furnace, and use a zinc oxide target to deposit a ZnO film on the surface of the aluminum sheet. The specific method is as follows: place the zinc oxide at the target position, and The pole spacing is 5 cm; the magnetron sputtering furnace is evacuated to a vacuum degree of 3.0×10 -4 Pa, filled with argon gas to a pressure of 10 Pa, cleaning and activating the surface of the aluminum sheet; filled with a mixed gas of oxygen and argon to a pressure of 30 Pa, the pressure ratio of oxygen and argon in the mixed gas is 1:3, splashing The injection power is 60W, adjust the temperature in the magnetron sputtering furnace to 380°C, and keep it warm for 5 hours; turn off the power,...

Embodiment 3

[0031] The method for plating ZnO thin film on the surface of aluminum sheet comprises the following steps:

[0032] (1) The surface of the aluminum sheet is polished, and ultrasonic cleaning is carried out with acetone;

[0033] (2) Put the ultrasonically cleaned aluminum sheet into a magnetron sputtering furnace, and use a zinc oxide target to deposit a ZnO film on the surface of the aluminum sheet. The specific method is as follows: place the zinc oxide at the target position, and The pole spacing is 4cm; the magnetron sputtering furnace is evacuated to a vacuum degree of 1.0×10 -4 Pa, fill in argon to a pressure of 10 Pa, clean and activate the surface of the aluminum sheet; fill in a mixed gas of oxygen and argon to a pressure of 35Pa, the pressure ratio of oxygen and argon in the mixed gas is 1:2, the power 70W, adjust the temperature in the magnetron sputtering furnace to 360°C, keep warm for 2 hours; turn off the power, and vacuum the magnetron sputtering furnace to a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

| dispersion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com