Spirally wound lithium-air solid state battery with replaceable electrodes

A solid-state battery, wound-type technology, applied in the direction of electrical components, battery electrodes, fuel cell half-cells and secondary battery-type half-cells, etc., can solve the problem that the positive and negative electrodes of lithium-air batteries cannot be fully utilized, To achieve the effect of convenient and quick replacement operation, avoid waste, and tight connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

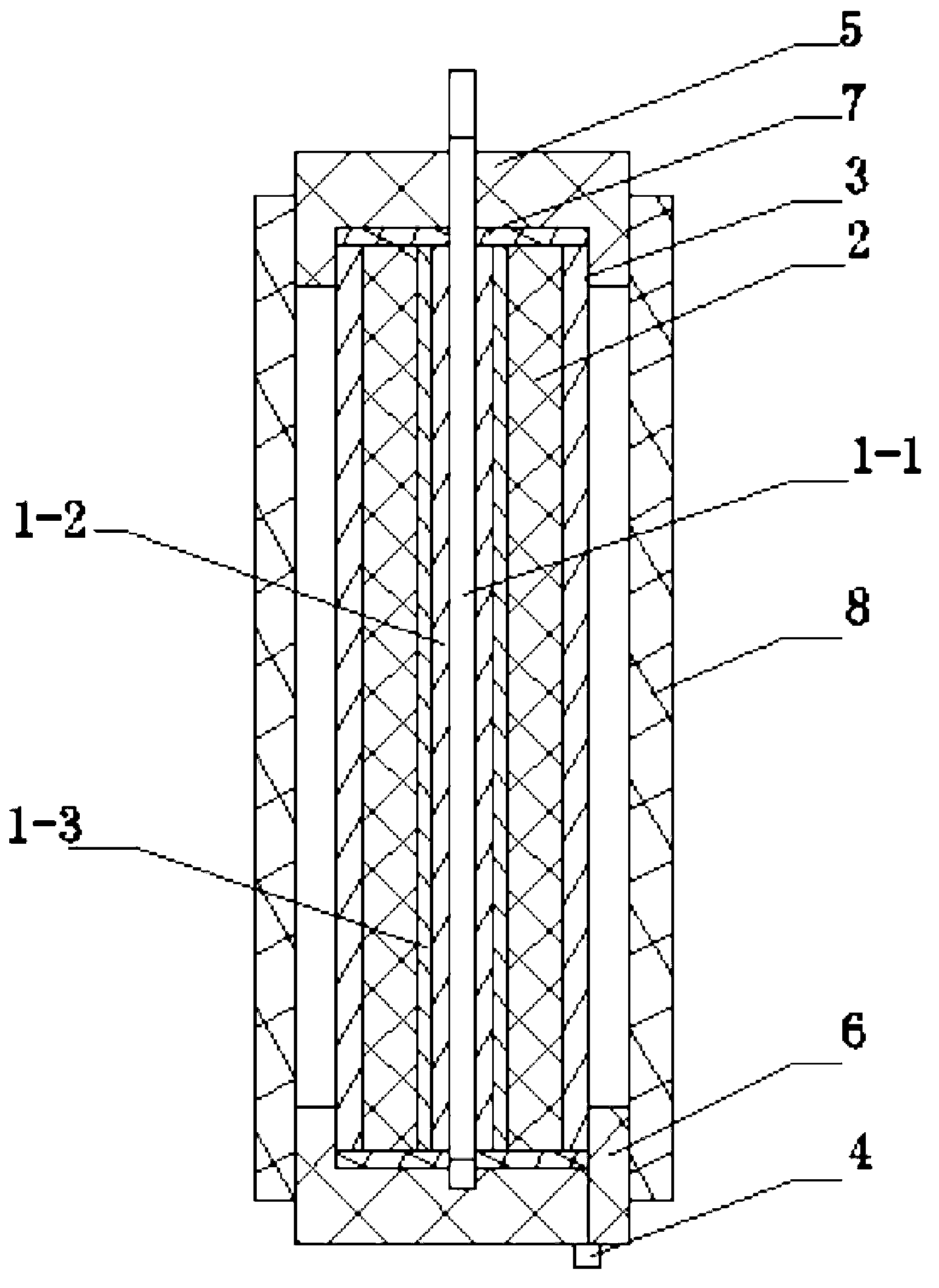

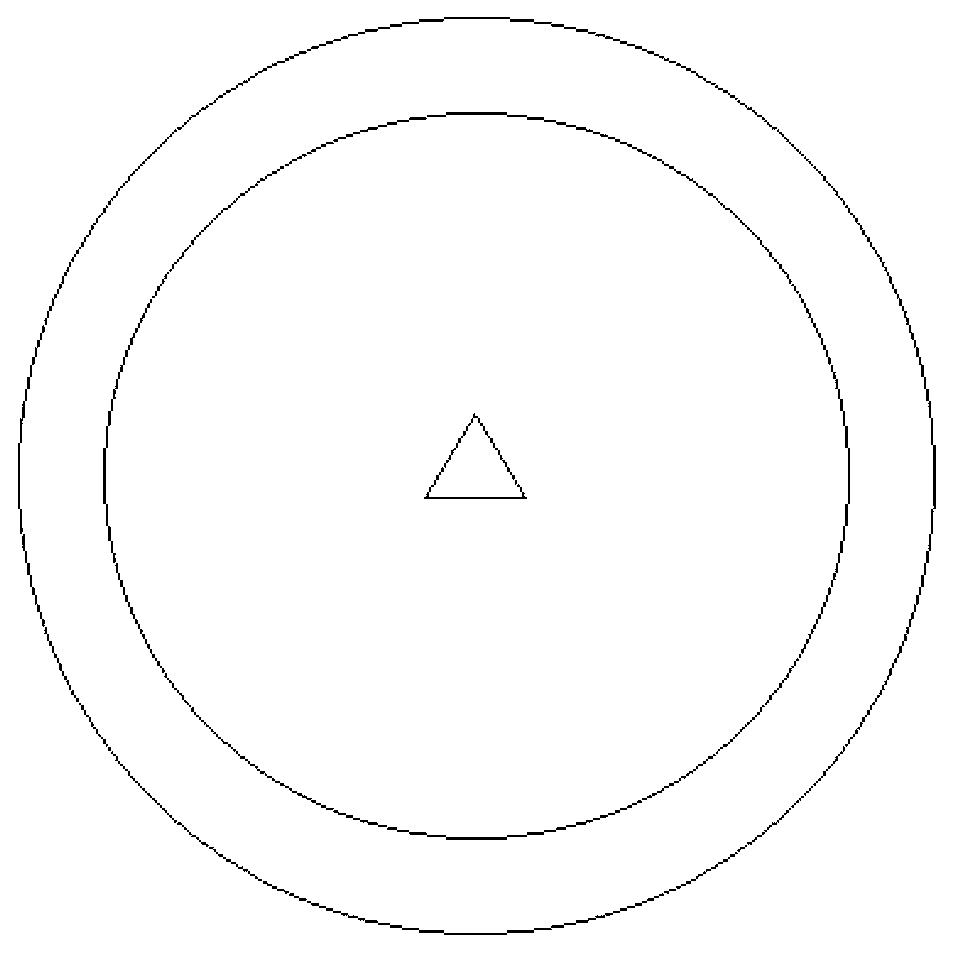

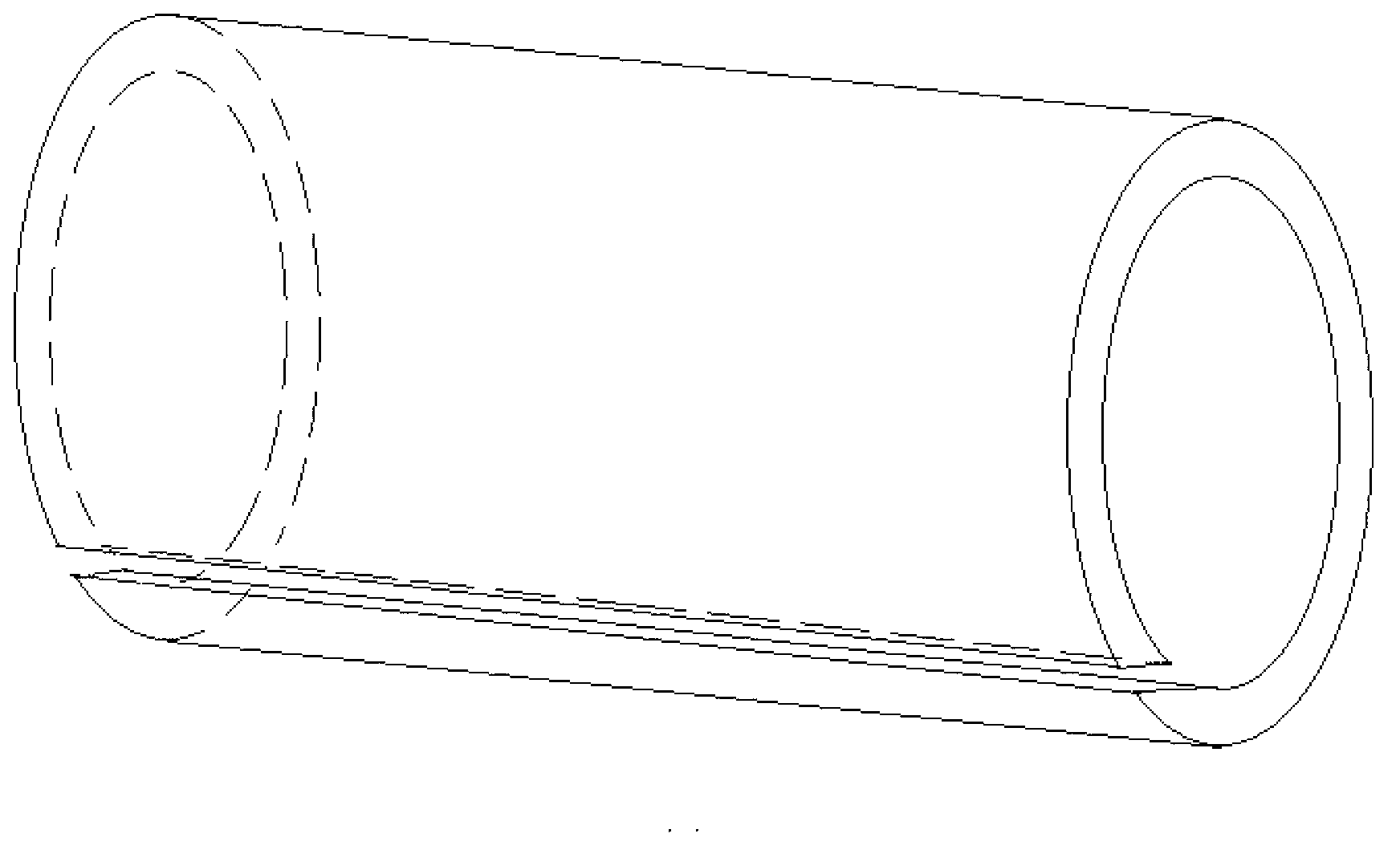

[0018] Embodiment 1: In this embodiment, a wound-type lithium-air solid-state battery with replaceable electrodes consists of a conductive rod 1-1, a conductive sheet 1-2, a negative electrode sheet 1-3, a gel electrolyte-air positive electrode combination 2, and a positive electrode A current collector 3, a positive electrode lead connector 4, a negative electrode gas seal head 5, a positive electrode gas seal head 6, an airtight diaphragm 7 and a ventilating casing 8; wherein, the upper end of the conductive rod 1-1 is a negative electrode connector, and the negative electrode connector has an external thread. The conductive rod 1-1 is the central axis, the conductive rod 1-1 is welded to one end of the conductive sheet 1-2, the other end of the conductive sheet 1-2 is hooked to the negative electrode sheet 1-3, and the conductive sheet 1-2 is connected to the negative electrode sheet 1-2. 3 The whole is tightly wound on the surface of the conductive rod 1-1, and the surface ...

specific Embodiment approach 2

[0021] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the positive current collector 3 is made of stainless steel, copper alloy, aluminum alloy, magnesium alloy, nickel alloy, titanium alloy, polyacetylene or linear polyphenylene. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0022] Specific embodiment 3: The difference between this embodiment and specific embodiment 1 or 2 is that the material of the negative gas sealing head 5 is polytetrafluoroethylene, polyvinylidene fluoride, polystyrene, polypropylene, polyimide, phenolic Resin, polyvinyl chloride, polychlorotrifluoroethylene or polyethylene, and the material of the positive gas sealing head 6 is polytetrafluoroethylene, polyvinylidene fluoride, polystyrene, polypropylene, polyimide, phenolic resin, polychlorinated Ethylene, polychlorotrifluoroethylene or polyethylene. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com