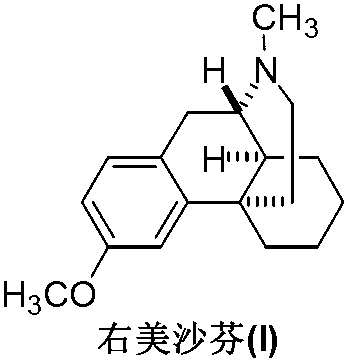

Method for preparing dextromethorphan

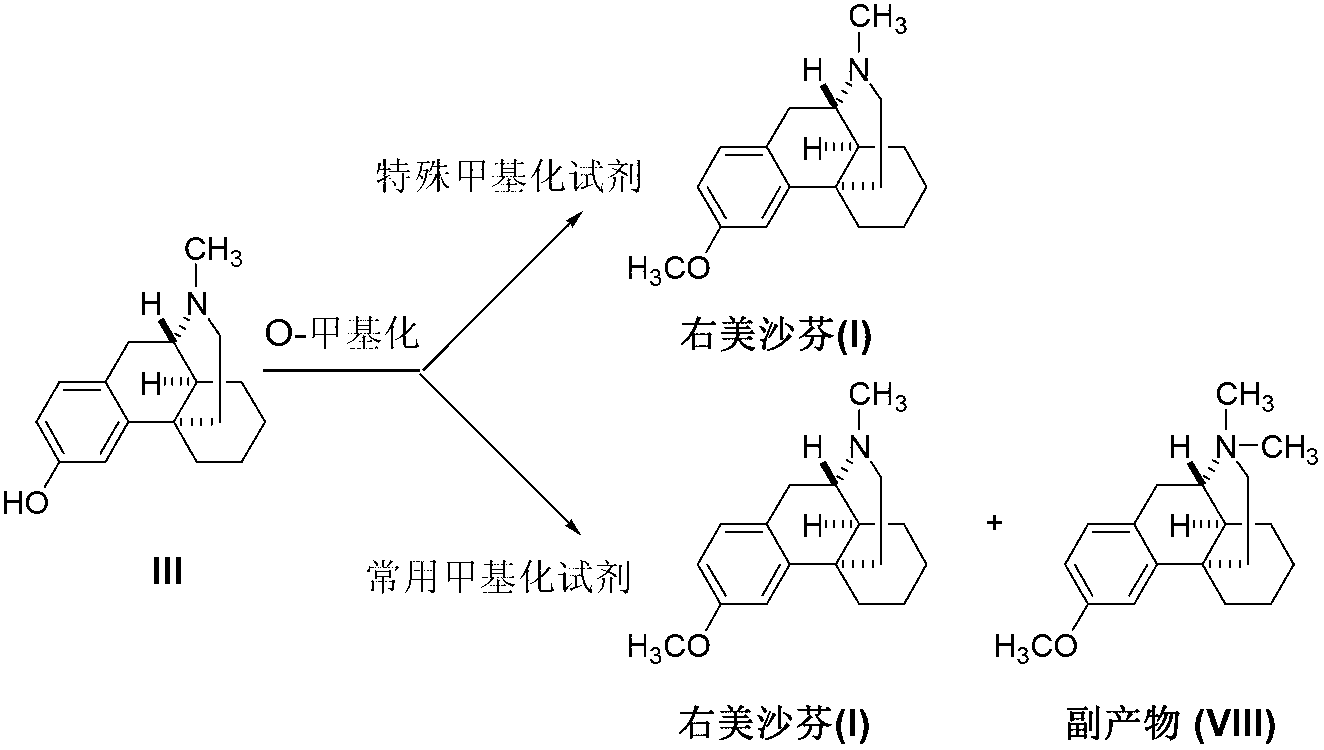

A technology of dextromethorphan and reaction, which is applied in the field of preparation of dextromethorphan, can solve the problems of high price of trimethylphenyl ammonium hydroxide, increased production cost of dextromethorphan, and difficulty in obtaining it, and achieve the goal of promoting economic and technological development Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

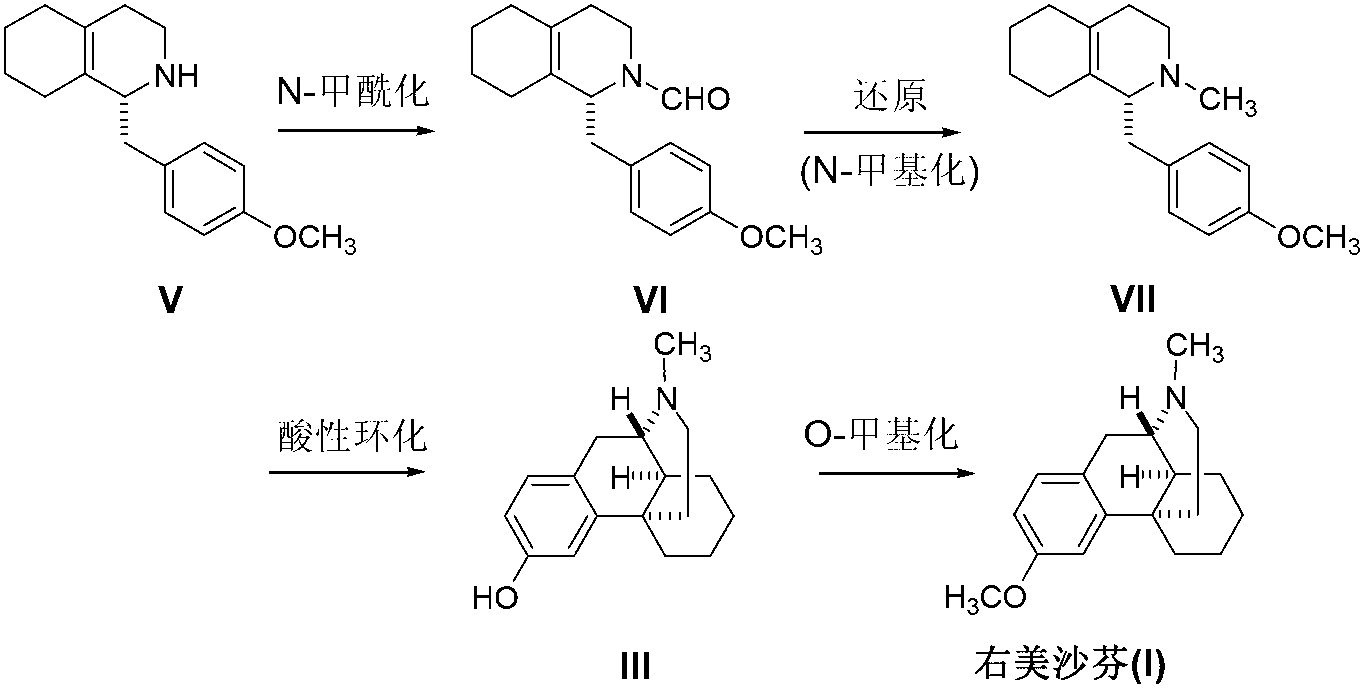

Method used

Image

Examples

Embodiment 1

[0021] Example 1: Intermediate (II) (25.7 g, 0.1 mol), 40% formaldehyde (15.0 g, 0.2 mol) and 200 mL of methanol were successively added to a 500 mL three-necked flask, and the reaction was stirred slowly for 12 hours. Transfer the reaction solution into a hydrogenation reactor, add 3 g of Raney nickel, keep room temperature and a pressure of 2-4 kg, react for 4 hours, and TLC detects that the reaction is complete. The catalyst was recovered by filtration, the mother liquor was concentrated under reduced pressure, and the residue was recrystallized from methanol to obtain 22.5 g of off-white solid dextromethorphan (I), with a yield of 83.0%.

Embodiment 2

[0022] Embodiment two: add intermediate (II) (25.7g, 0.1mol), paraformaldehyde (6.0g, 0.2mol), solid potassium carbonate (13.8g, 0.1mol), methanol 150mL and Add 50 mL of water, raise the temperature to 65-75°C, and start stirring to react for 6 hours. The reaction solution was transferred to a hydrogenation reactor, 3 g of palladium carbon was added, the temperature was raised to 40-45° C., the pressure was kept at 2-4 kg, and the reaction was carried out for 6 hours, and the TLC detection reaction was completed. The catalyst was recovered by filtration, the mother liquor was concentrated under reduced pressure, and the residue was recrystallized from methanol to obtain 23.8 g of off-white solid dextromethorphan (I), with a yield of 87.8%.

Embodiment 3

[0023] Example three: Add intermediate (II) (25.7g, 0.1mol), sodium methoxide (10.8g, 0.2mol), 150mL of methyl formate successively in a 500mL three-necked flask, heat up to 50-55°C, and stir the reaction After 6 hours, TLC detected that the reaction was complete. The solvent was removed under reduced pressure, and the residue was dissolved in ethanol. Add sodium borohydride (4.6 g, 0.12 mol) in batches, and react at room temperature for 12 hours, and TLC detects that the reaction is complete. The mother liquor was concentrated, and the residue was dissolved in ethyl acetate, washed with dilute hydrochloric acid and water to neutrality, and dried over anhydrous sodium sulfate. Concentrate under reduced pressure, and recrystallize the residue from methanol to obtain 21.6 g of off-white solid dextromethorphan (I), with a yield of 79.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com