CIGS (copper indium gallium selenium) thin film solar cell and preparation method thereof

A technology of solar cells and copper indium gallium selenide, which is applied in the field of solar cells, can solve problems such as difficult to accurately control Ga, CIGS is not easy to reach a parabolic state, etc., to achieve the effect of improving photoelectric conversion efficiency, improving photoelectric conversion efficiency, and ensuring repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

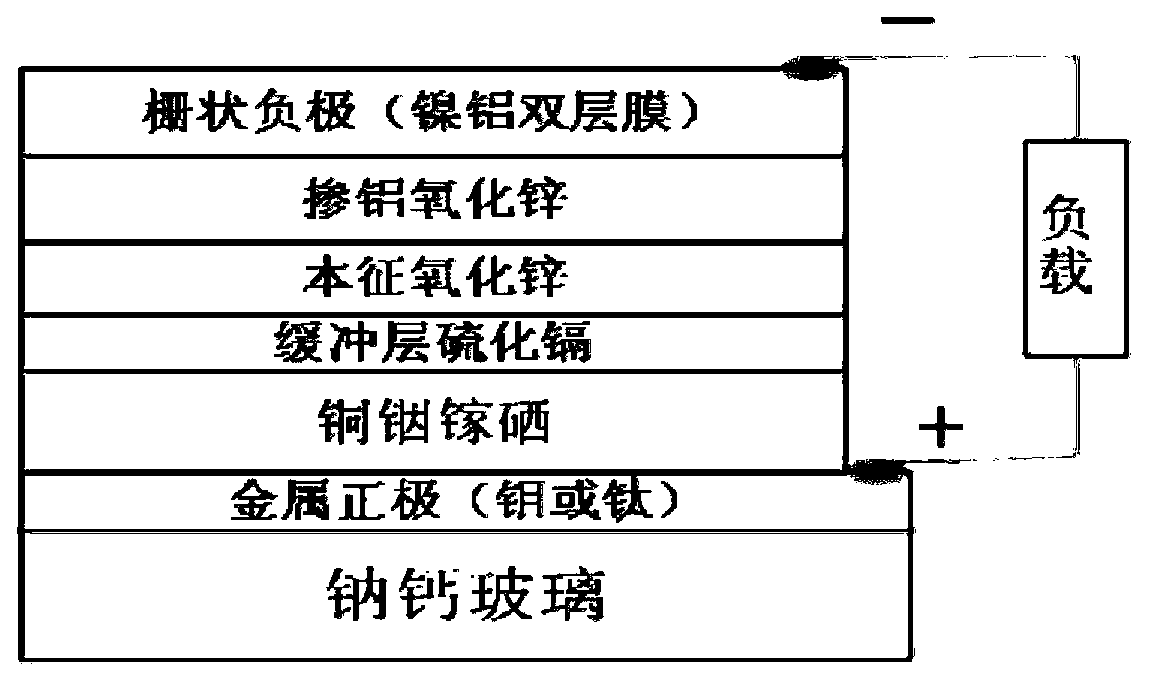

[0052] A kind of preparation method of copper indium gallium selenide thin film solar cell, its specific scheme is as follows:

[0053] The substrate, metal positive electrode, light absorbing layer, buffer layer, window layer, transparent electrode layer and grid-shaped metal negative electrode are sequentially connected and assembled into a copper indium gallium selenide thin film solar cell;

[0054] Each copper indium gallium selenide monolayer of the light absorbing layer is directly formed into a film by adjusting the magnetron sputtering gas pressure, magnetron sputtering temperature range and magnetron sputtering power density, or preparing a prefabricated layer by magnetron sputtering, Then put the prefabricated layer under the protection of argon or nitrogen for 400~500 o C selenization treatment to form copper indium gallium selenide film; wherein the magnetron sputtering gas pressure is 0.1~10 Pa, and the magnetron sputtering temperature range is 200~600 o C, the ...

Embodiment 1

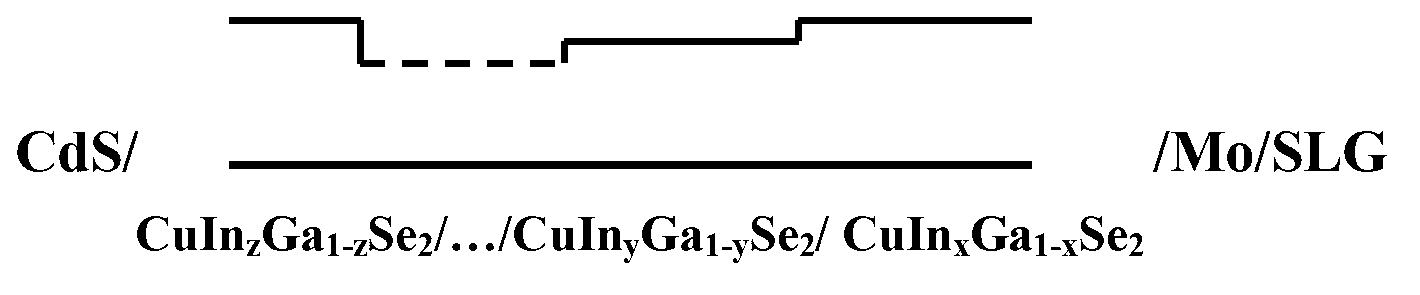

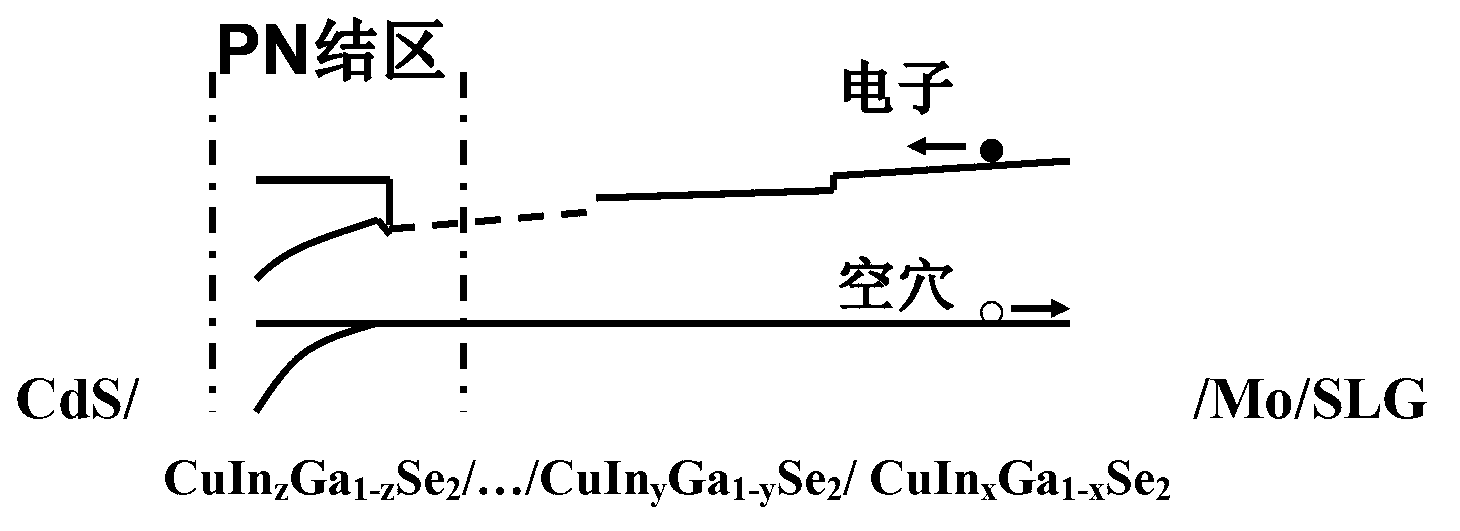

[0057] The copper indium gallium selenide thin film solar cell prepared in this embodiment includes a light absorption layer, which is arranged between the metal positive electrode and the buffer layer, and the light absorption layer is composed of two layers of copper indium gallium selenide with different energy gaps. The composition of the thin film, and the Ga composition in the CIGS single layer adjacent to the buffer layer is greater than the Ga composition in the remaining CIGS single layers.

[0058] The Ga composition refers to the atomic ratio of Ga / (In+Ga) in the CIGS thin film.

[0059] The atomic ratio of Ga / (In+Ga) in the single layer of copper indium gallium selenide adjacent to the metal positive electrode is 0.233, and its thickness is 300 nm; the atomic ratio of Ga / (In+Ga) in the second single layer of copper indium gallium selenide The ratio is 0.294, and its thickness is 300 nm;

[0060]The copper indium gallium selenide thin film solar cell of this embodi...

Embodiment 2

[0063] The copper indium gallium selenide thin film solar cell of this embodiment includes a light absorption layer, the light absorption layer is arranged between the metal positive electrode and the buffer layer, and the light absorption layer is composed of three layers of copper indium gallium selenide thin films with different energy gaps , the Ga composition in each CIGS monolayer is fixed, and the Ga composition in the CIGS monolayer adjacent to the buffer layer is greater than the Ga composition in the remaining CIGS monolayers.

[0064] The atomic ratio of Ga / (In+Ga) in the single layer of copper indium gallium selenide adjacent to the metal positive electrode is 0.302, and its thickness is 300 nm; the atomic ratio of Ga / (In+Ga) in the second single layer of copper indium gallium selenide ratio is 0.295, and its thickness is 300 nm; the atomic ratio of Ga / (In+Ga) in the third CIGS monolayer (the CIGS monolayer adjacent to the buffer layer) is 0.325, and its thickness i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com